Processing technology of black locust flower substitute tea

A kind of processing technology, the technology of locust flower, applied in the field of processing technology of locust flower substitute tea, achieves the effect of improving mental state, rich and fragrant aroma, simple and easy processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

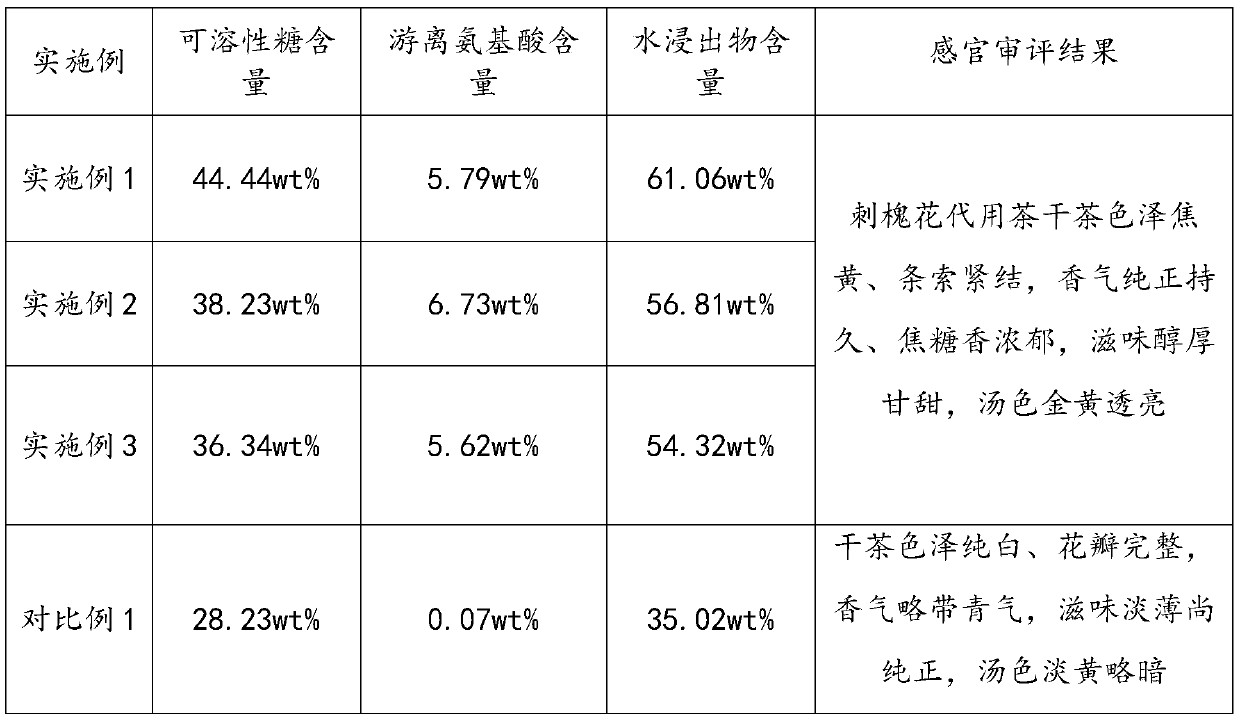

Examples

Embodiment 1

[0029] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0030] B. Lay the treated black locust flower in step A on the bamboo raft sieve naturally, with a thickness of 1.5cm, spread it at 15°C until the water content of the black locust flower is 65wt%, and turn it up and down once every 4 hours during the cooling period ,spare;

[0031] C, stir-fry the black locust flower after being cooled in step B at 100°C until the water content of the black locust flower is 35wt%, then spread it cool for 30min, and set aside;

[0032] D, stir-fry the black locust flower after being cooled in step C at 80°C until the water content of the black locust flower is 15wt%, then spread it for 20 minutes, and set aside;

[0033] E. Place the cooled locust flower in the step D in an oven at 70° C., and bake until the water content of the locust flower is 5 wt%, to obtain the...

Embodiment 2

[0035] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0036] B. Lay the processed black locust flower in step A on the bamboo raft sieve naturally, with a thickness of 1.8cm, spread it at 20°C until the water content of the black locust flower is 68wt%, and turn it up and down once every 4 hours during the cooling period ,spare;

[0037] C, stir-fry the black locust flower after being cooled in step B at 105°C until the water content of the black locust flower is 38wt%, then spread it for 40 minutes, and set aside;

[0038] D, stir-fry the black locust flower after being cooled in step C at 85°C until the water content of the black locust flower is 18wt%, then spread it cool for 25 minutes, and set aside;

[0039] E. Place the cooled locust flower in step D in an oven at 75° C., and bake until the water content of the locust flower is 6 wt%, to obtain ...

Embodiment 3

[0041] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0042] B. Lay the processed black locust flower in step A on the bamboo raft sieve naturally, with a thickness of 2.0cm, spread it at 25°C until the water content of the black locust flower is 70wt%, and turn it up and down once every 4 hours during the cooling period ,spare;

[0043] C, stir-fry the black locust flower after being cooled in step B at 110°C until the water content of the black locust flower is 40wt%, then spread it cool for 60min, and set aside;

[0044] D, stir-fry the black locust flower after being cooled in step C at 90°C until the water content of the black locust flower is 20wt%, then spread it for 30 minutes, and set aside;

[0045] E. Place the black locust flower cooled in step D in an oven at 80° C., and bake until the water content of the black locust flower is 8 wt%, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com