Waste centrifugal extractor

A centrifugal extractor and waste technology, which is applied in solvent extraction, liquid solution solvent extraction, separation methods, etc., can solve the problems of insufficient mixing and separation effect of light and heavy phases, vibration of centrifugal extractor, and limitation of rotating drum speed, etc. Improve mixing and separation effect, separate sufficient, reduce the effect of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

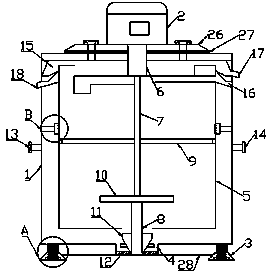

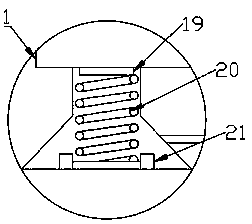

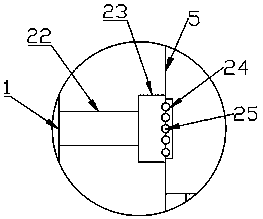

[0021] Such as figure 1 It is a structural schematic diagram of the present invention, a waste centrifugal extractor, including a casing 1, a centrifugal motor 2 is arranged on the top surface of the casing 1, a base 3 is arranged on the bottom surface of the casing 1, and a There is a shock absorbing device, a mixing tank 4 is arranged on the housing 1 between the bases 3, a drum 5 is arranged inside the housing 1, and a stabilizing device is arranged between the drum 5 and the housing 1, The drum 5 and the housing 1 are provided with a first transmission shaft 6 , a second transmission shaft 7 and a third transmission shaft 8 , and the second transmission shaft 7 is arranged on the first transmission shaft 6 and the third transmission shaft 8 Between, the other end of the first transmission shaft 6 passes through the top surface of the housing 1 and is connected to the centrifugal motor 2, the other end of the third transmission shaft 8 is rotationally connected to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com