Continuous material belt type metal piece efficient cutting mechanism

A technology of metal parts and strips, which is applied in the field of efficient cutting mechanism for continuous strips of metal parts, can solve the problems of increased maintenance frequency, tool cost, increased cleaning process, and high heat generation of equipment, so as to reduce the probability of pollution and save The effect of removing the cleaning process and reducing the heat generated by the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

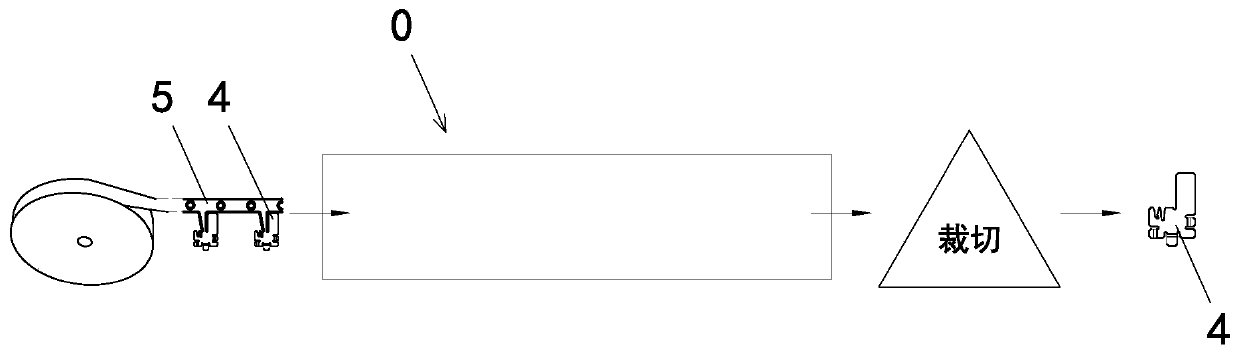

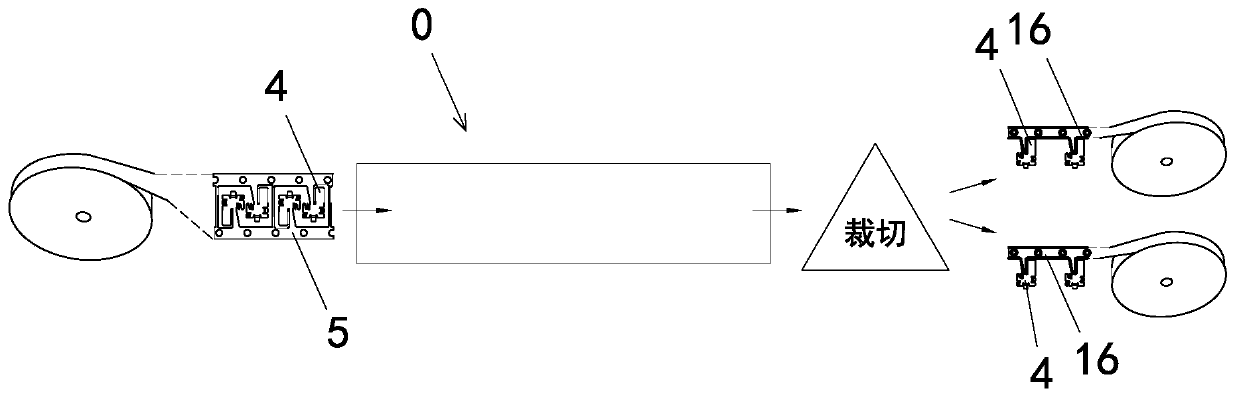

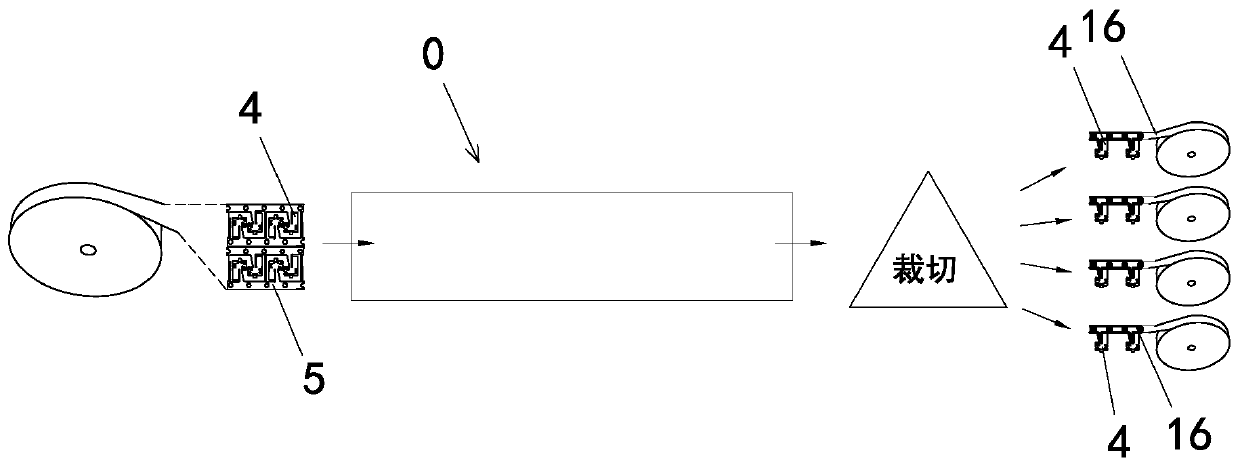

[0054] Example: see attached Figure 1~16 As shown in the figure, a continuous strip-type metal parts efficient cutting mechanism can be directly connected in series to the discharge port of the electroplating equipment 0. It includes a frame 1, and also includes at least one pair of feed guide wheels, a pair of rotating shear wheels and a pair of discharge guide wheels that are rotated and positioned in the frame 1 from front to back, and the feed The rotating shafts of the guide wheel, the rotary shearing wheel and the discharge guide wheel are all arranged in parallel.

[0055] Said at least one pair of feed guide wheels comprises a first feed guide wheel 2 and a second feed guide wheel 3, both of which are arranged in pairs in the up and down direction and at least one of them is a driving wheel; said first feed guide wheel The guide wheel 2 and the second feed guide wheel 3 at least limit the material belt 5 of the metal piece 4 to be cut in the up and down direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com