Automatic conveying and welding rotating device for vertical tube well vertical pipeline and using method thereof

A technology of vertical pipes and rotating devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited mechanization degree by site and low utilization rate of mechanization, so as to improve the level of mechanization and welding quality, and reduce the impact of delivery. , The effect of reducing the risk of edge operation and high-altitude hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

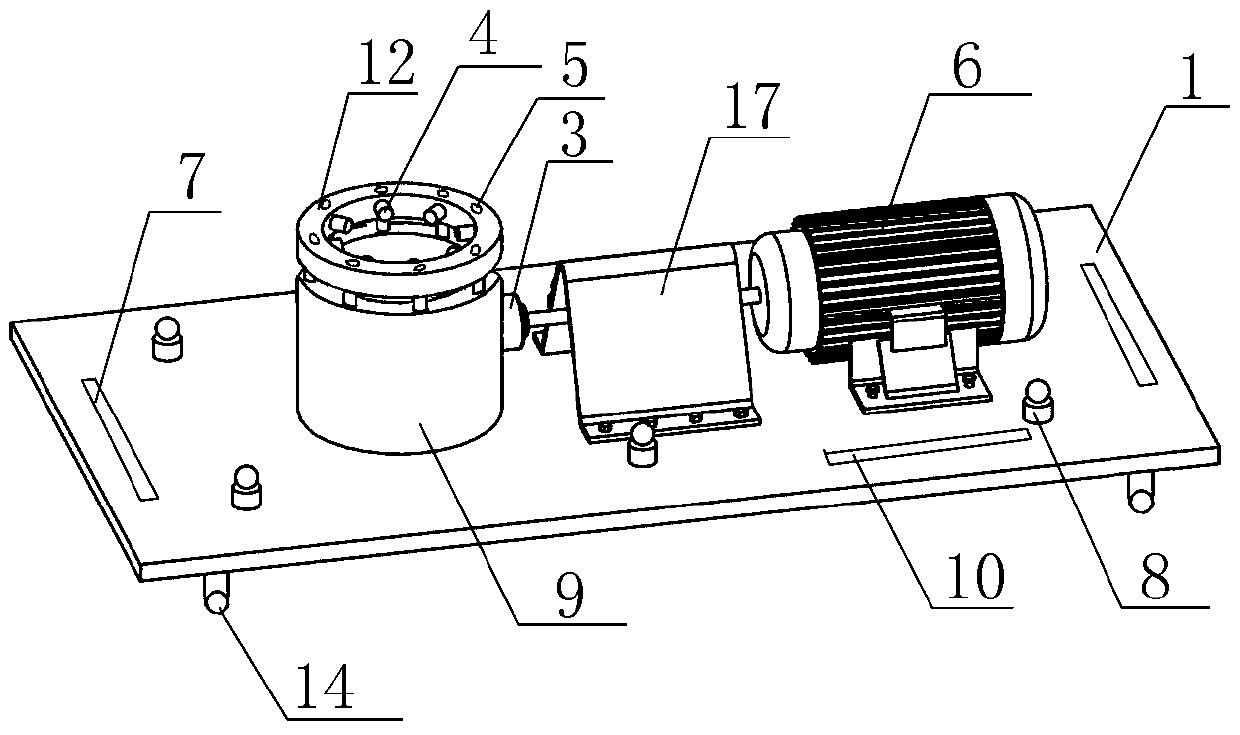

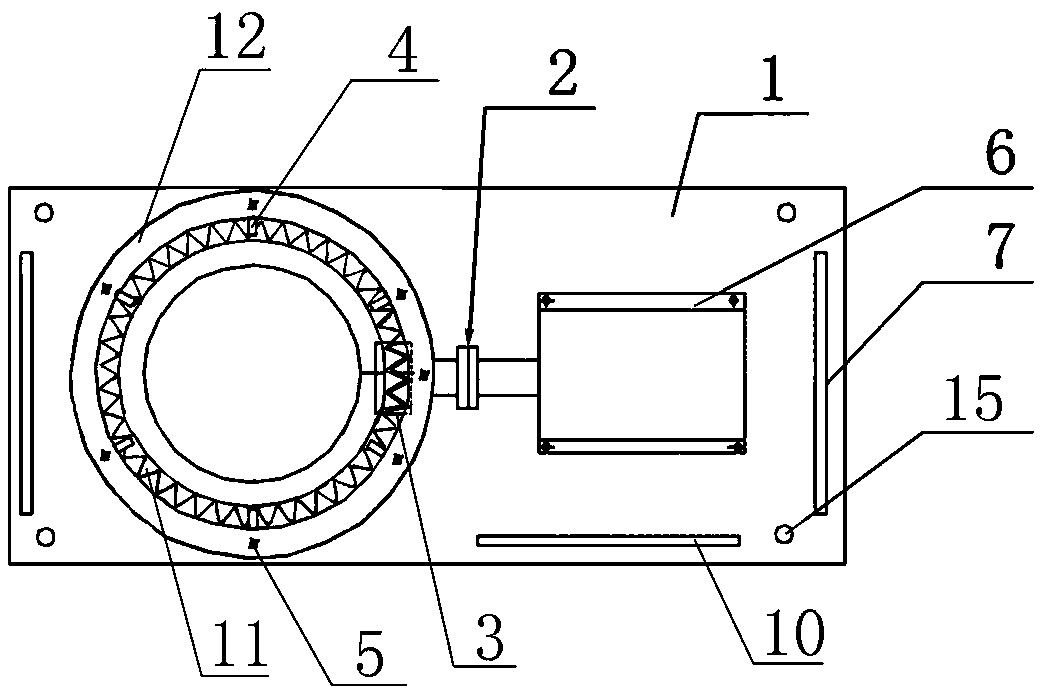

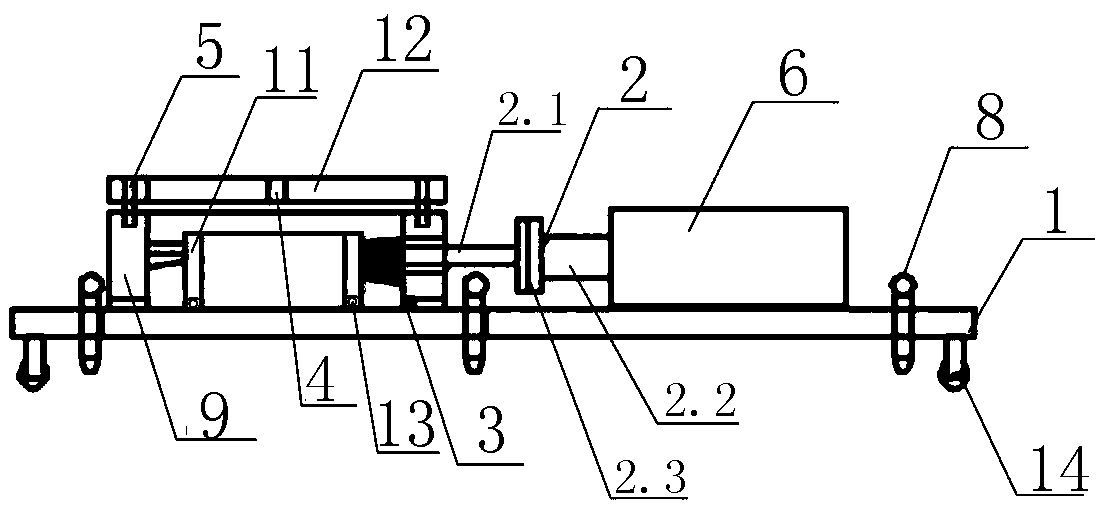

[0031] like Figure 1-5 As shown, this riser well vertical pipeline automatic transmission welding rotary device is used in conjunction with the vertical pipeline construction flip technology of the riser well, and includes a base 1; the left and right sides of the base 1 are respectively provided with longitudinal Scale 7; Between the two longitudinal scales 7, a frequency conversion servo motor 6, a transmission device and a rotating device are arranged in sequence along the horizontal direction; the frequency conversion servo motor 6 is fixedly connected to the base 1, and has a frequency conversion speed regulation function; the transmission The device includes an angular meshing gear 3 and a transmission shaft 2 connected between the variable frequency servo motor 6 and the angular meshing gear 3; the angular meshing gear 3 is driven by the transmission shaft 2 to rotate around a horizontal axis; the rotating device includes There are a protective sleeve 9, a horizontal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com