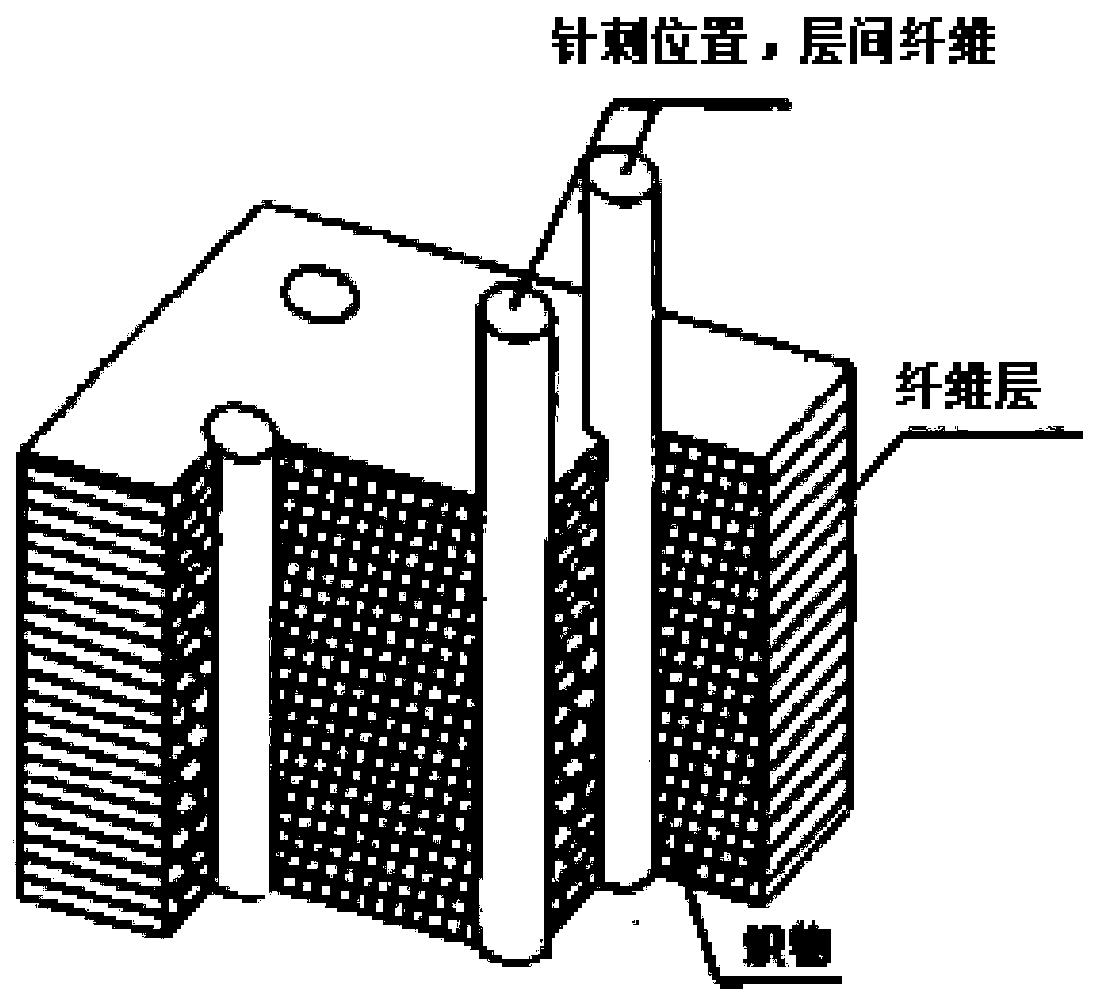

Method for soaking high-fall three-dimensional needling structure in low viscosity resin

A low-viscosity resin, high drop technology, used in other home appliances, home appliances, household components, etc., can solve the problems of uneven density, low resin viscosity, and large height drop between layers, achieving high degree of realization and technical difficulty. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

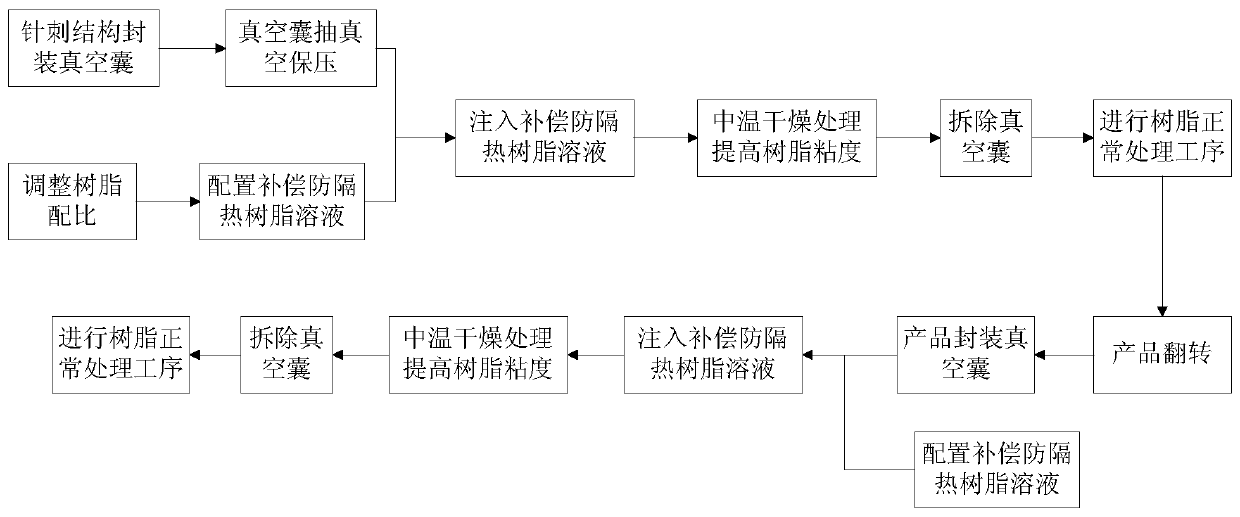

Embodiment 1

[0056] In the preparation of preform density 0.4g / cm 3 , when the three-dimensional needle-punched flat plate preform with a size of 500mm×500mm×80mm is used, the vertical dipping method is adopted, and the maximum height difference is 500mm. The phenolic resin with a glue content of 10% is dipped and diluted with ethanol. Use felt and vacuum bag film to wrap the workpiece, install a Φ10 aperture vacuum nozzle at a height of 300mm from the vertical upper side, and install a Φ30 aperture glue inlet interface at a distance of 300mm from the vertical lower side. Then the glue is injected and the glue inlet valve is closed. The whole is heated at 60°C, and after 4 hours of heat preservation, the bag is removed and placed vertically for resin drying and gel treatment. Then turn it over 180° to dip again, dry and solidify. Sampling at the highest point and the lowest point during the final product forming process, the density difference is 0.09g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com