Multi-layer sintering mold and sintering method for boron carbide absorbers for nuclear reactor

A nuclear reactor and boron carbide technology, applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of low density in the middle of sintered parts, low output and yield, poor density consistency, etc., to achieve density and size deviation Small, production The effect of shortening the cycle time and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

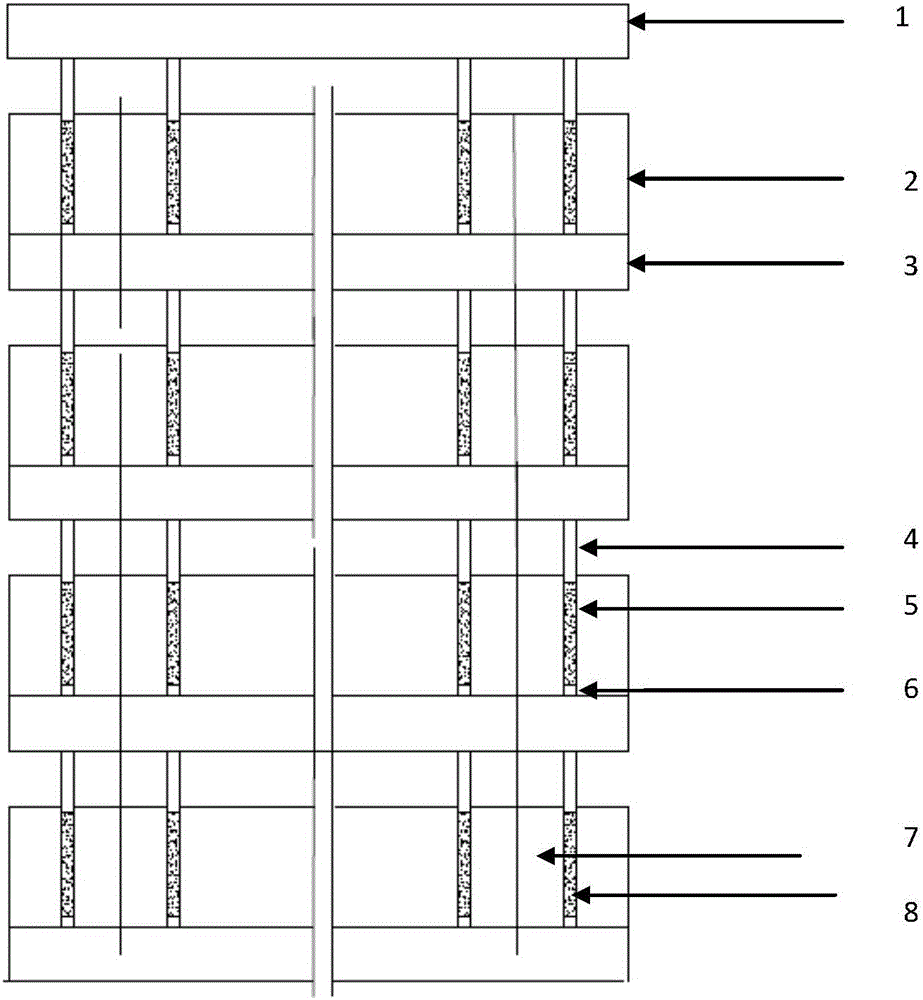

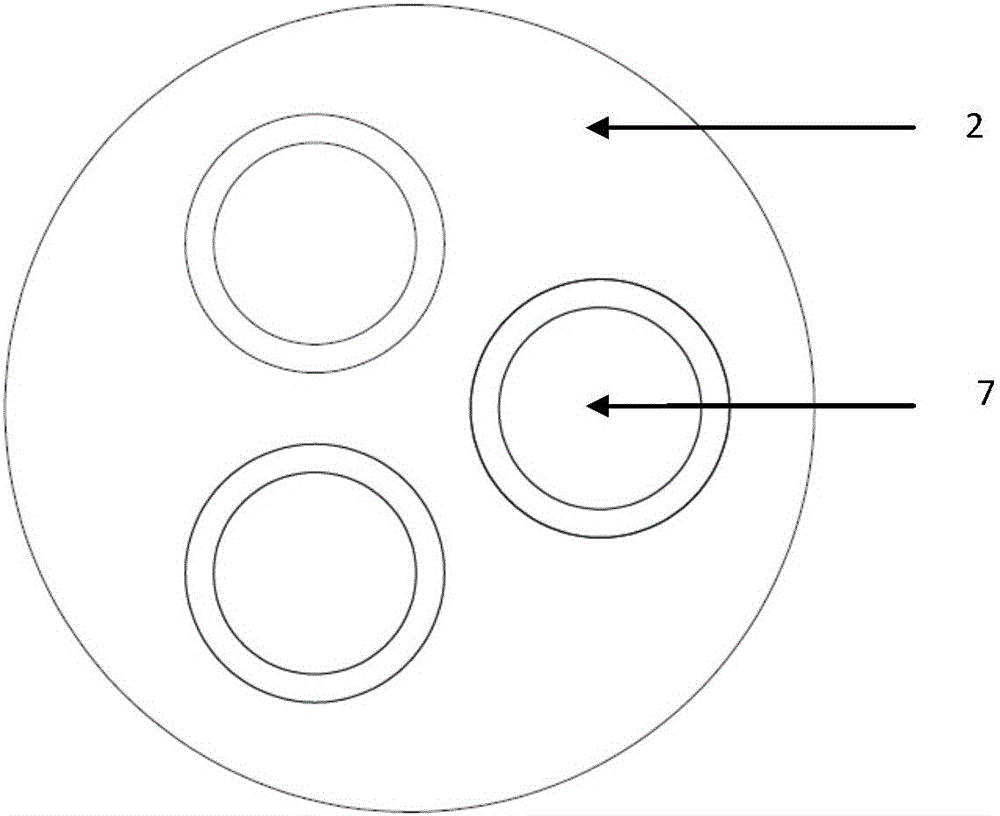

[0024] Assemble the mold, each layer of mold is composed of a lower support plate, a porous mold plate and an upper cover plate, the parallelism of the mold is less than 0.05mm; the porous mold plate contains 100 holes, each hole is equipped with a combined mold, the volume of the inner hole of the combined mold The deviation is less than 0.5%; a gap of 0.1mm should be reserved between the components of the composite mold. Select nuclear-grade boron carbide powder with a particle size D50 of 10 μm, weigh the powder with a mass deviation of less than 0.5%, and add it to the holes of the combined mold; combine the five-layer molds together and hang them into the hot-press sintering furnace.

[0025] Vacuumize the sintering furnace to below 100pa, heat up to 1000°C at a heating rate of 3°C / min, fill it with high-purity argon to gauge pressure -0.1Mpa, continue to heat up to 1400°C, evacuate, and heat up to 1800°C for 0.5 hours , natural cooling, out of the oven. The mechanical p...

Embodiment 2

[0027] Assemble the mold, each layer of mold is composed of a lower support plate, a porous mold plate and an upper cover plate, the parallelism of the mold is less than 0.05mm; the porous mold plate contains 10 holes, each hole is equipped with a combined mold, the volume of the inner hole of the combined mold The deviation is less than 0.5%; a gap of 4 mm should be reserved between the components of the composite mold. Select nuclear-grade boron carbide powder with a particle size D50 of 30 μm, weigh the powder with a mass deviation of less than 0.5%, and add it to the holes of the combined mold; combine the three-layer molds together and hang them into the hot-press sintering furnace.

[0028] Vacuumize the sintering furnace to below 100pa, heat up to 1000°C at a heating rate of 10°C / min, fill it with high-purity argon to gauge pressure -0.1Mpa, continue to heat up to 1400°C, evacuate, and heat up to 2100°C for 0.5 hours , natural cooling, out of the oven. The mechanical p...

Embodiment 3

[0030] Assemble the mold, each layer of mold is composed of a lower support plate, a porous mold plate and an upper cover plate, the parallelism of the mold is less than 0.05mm; the porous mold plate contains 3 holes, each hole is equipped with a combined mold, the volume of the hole in the combined mold The deviation is less than 0.5%; a gap of 2mm should be reserved between the components of the composite mold. Select nuclear-grade boron carbide powder with a particle size D50 of 50 μm, weigh the powder with a mass deviation of less than 0.5%, and add it to the holes of the combined mold; combine the three-layer molds together and hang them into the hot-press sintering furnace.

[0031] Vacuumize the sintering furnace to below 100pa, heat up to 1000°C at a heating rate of 40°C / min, fill it with high-purity argon to gauge pressure -0.1Mpa, continue to heat up to 1400°C, evacuate, and heat up to 1900°C for 0.5 hours , natural cooling, out of the oven. The mechanical pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com