Energy-saving type water purifying system

A water purification system and energy-saving technology, applied in the field of water purification, can solve problems such as increased cost and difficulty, and achieve the effect of good purification effect and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

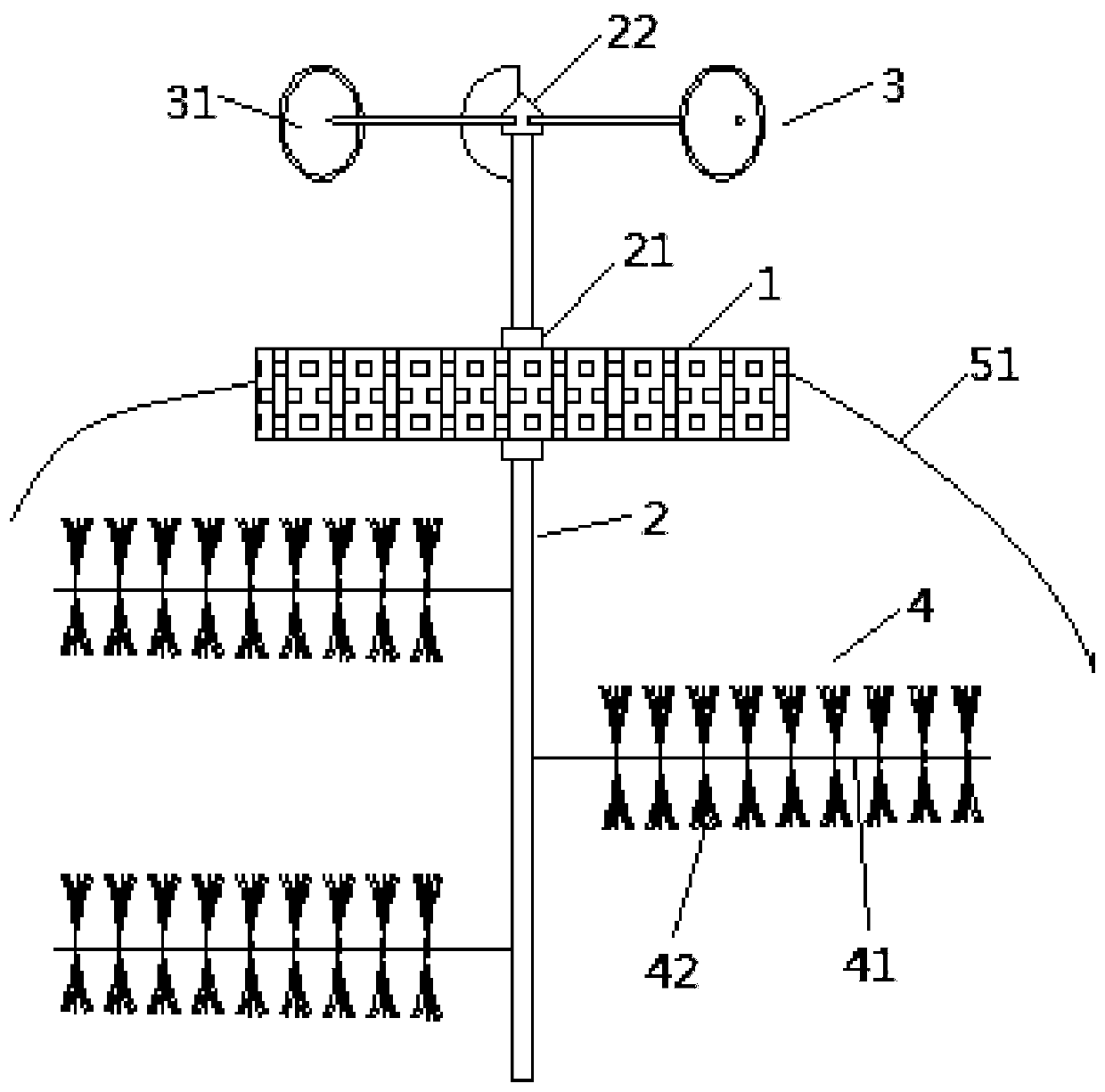

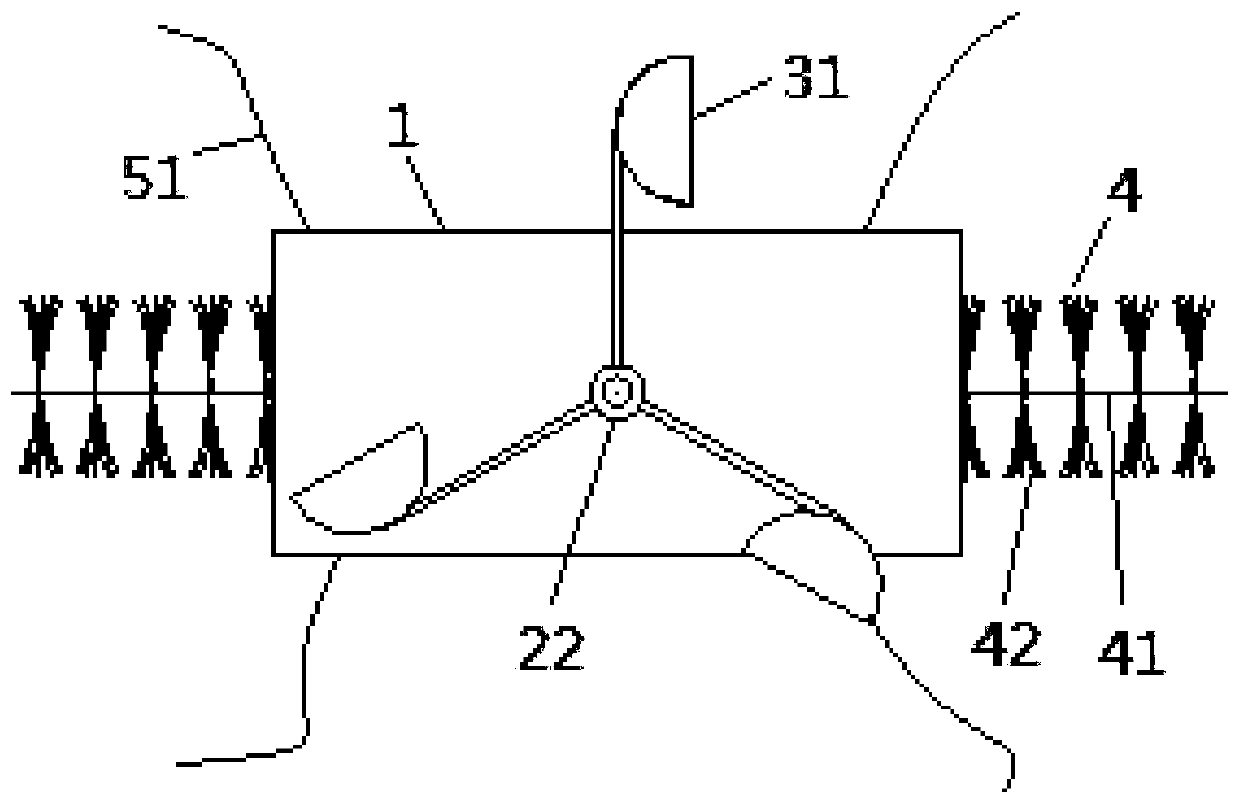

[0032] Embodiment one: if figure 1 and 2 As shown, the energy-saving water purification system of this embodiment includes a floating bed 1, which is used to float on the surface of a water body or in a water body; a rotating shaft 2, the above-mentioned rotating shaft 2 is vertically arranged, and its lower end runs through the above-mentioned floating bed 1 from top to bottom, and It is rotationally connected with the above-mentioned floating bed 1; the wind-driven structure 3, the above-mentioned wind-driven structure 3 is installed on the upper end of the above-mentioned rotating shaft 2, and is used to drive the above-mentioned rotating shaft 2 to rotate around its axis under the action of wind; the pollutant purification component 4, the above-mentioned pollutant purification The component 4 is installed at the lower end of the above-mentioned rotating shaft 2, and is used for purifying pollutants in the water body as the above-mentioned rotating shaft 2 rotates.

[003...

Embodiment 2

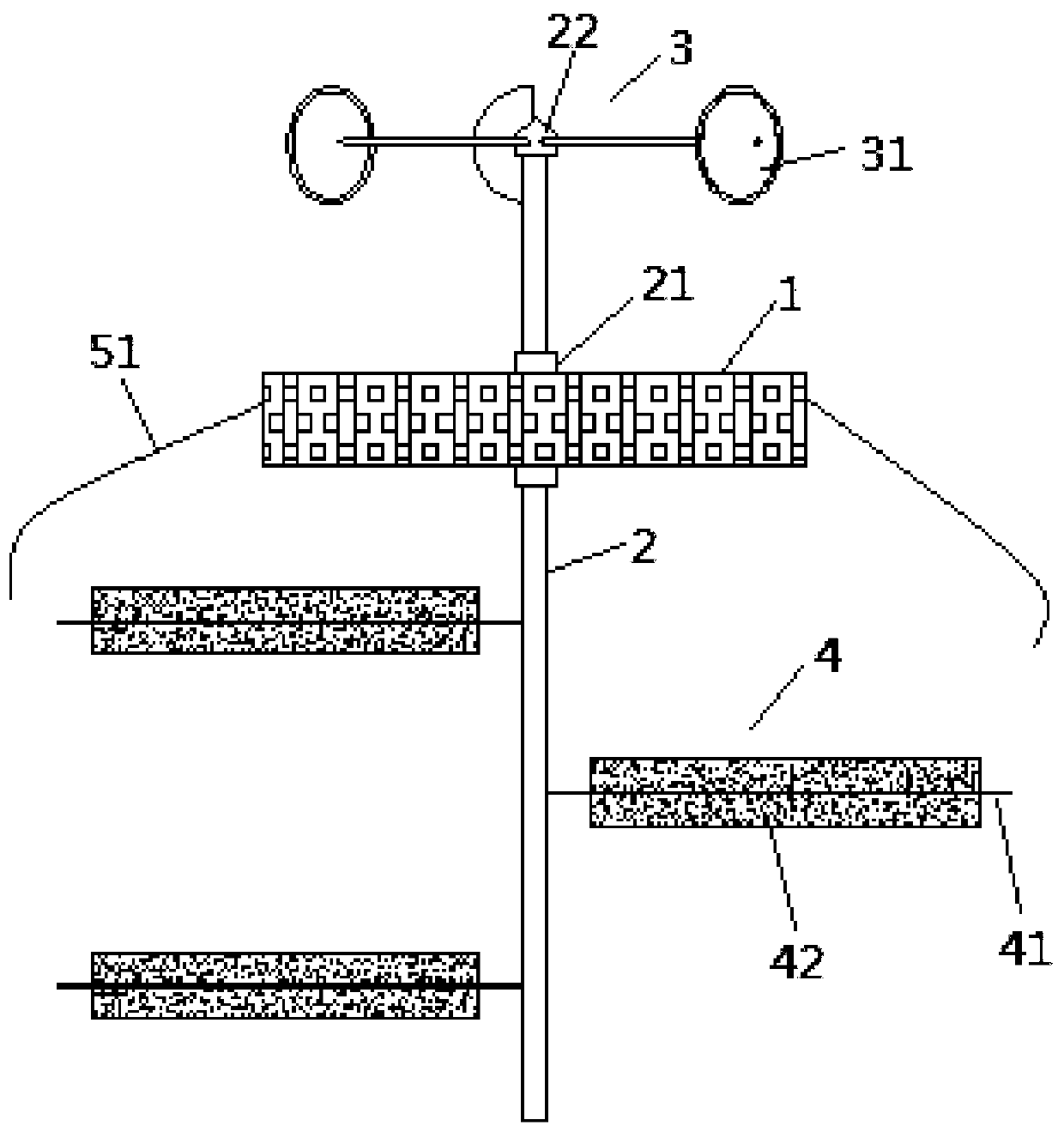

[0041] Embodiment two: if image 3 and 4 As shown, the above-mentioned pollutant purification units 42 are all solid adsorbent layers, and the above-mentioned adsorbent layers are wrapped and fixed on the outside of the support rod 41 along the length direction of the corresponding above-mentioned support rod 41, and the outside is wrapped with gauze. When there is wind, the wind force acts on the wind-driven structure 3, driving the wind-driven structure 3 to drive the rotating shaft 2 to rotate relative to the floating bed 1, thereby driving the pollutant purification assembly 4 at the lower end of the rotating shaft 2 to rotate, that is, the pollutant purification unit 42 ( Adsorbent layer) and the corresponding support rod 41 rotate with the rotating shaft 2, and the rotation of the adsorbent layer disturbs the water body to achieve the oxygenation effect, and the adsorbent layer can more fully contact the water body, and the pollutants in the water are removed by the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com