A near-infrared band full coverage rare earth doped multilayer luminescent glass and its preparation method and application

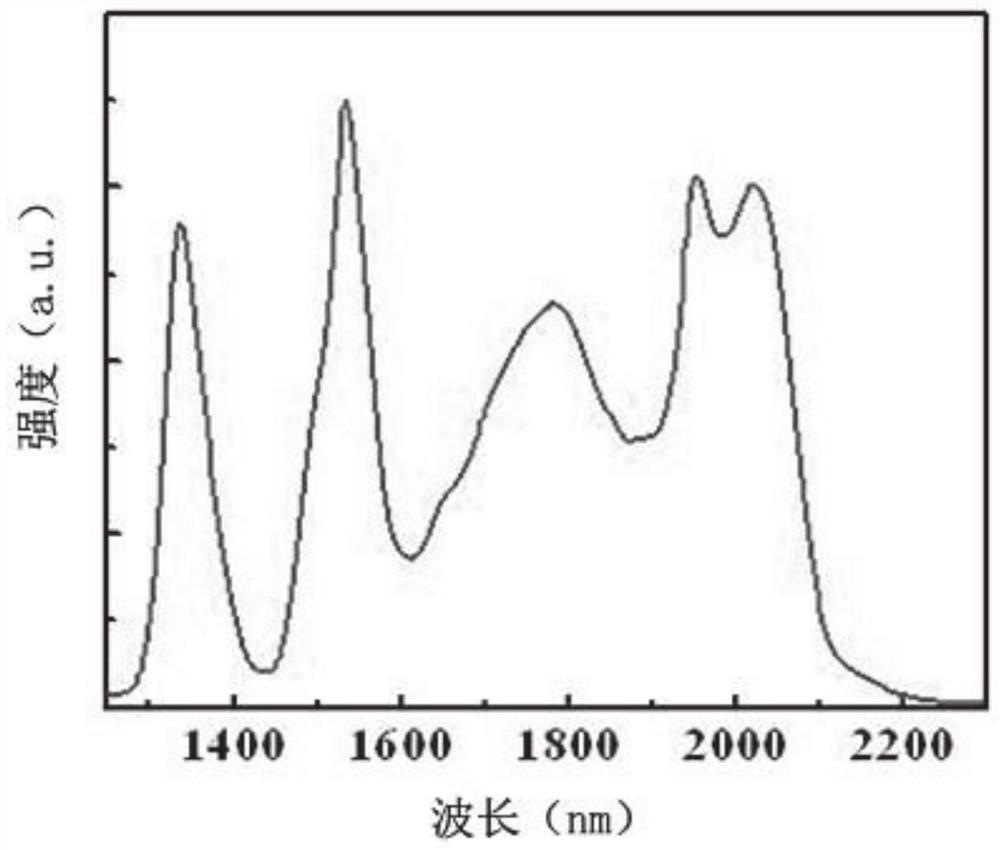

A luminescent glass and rare earth doping technology, which is applied in glass manufacturing equipment, glass furnace equipment, lasers, etc., can solve the problems of unfavorable miniaturization of near-infrared devices, single and discontinuous light-emitting bands, and large space occupation, and achieve the goal of overcoming single inconsistency Continuous, avoid luminescence quenching, and effectively adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A rare-earth-doped multilayer luminescent glass with full coverage in the near-infrared band of the present invention, the multilayer luminescent glass is composed of two layers of luminescent glass layers, wherein the first layer of luminescent glass layer is composed of the following molar ratios:

[0065] SiO 2 :PbF 2 : YbF 3 : TmF 3 :HoF 3 :ErF 3 =50:50:1.5:0.5:0.2:0.15

[0066] The second layer of luminescent glass layer is composed of the following molar ratios of each constituent raw material:

[0067] SiO 2 : PbF 2 :NdF 3 =50:50:0.3.

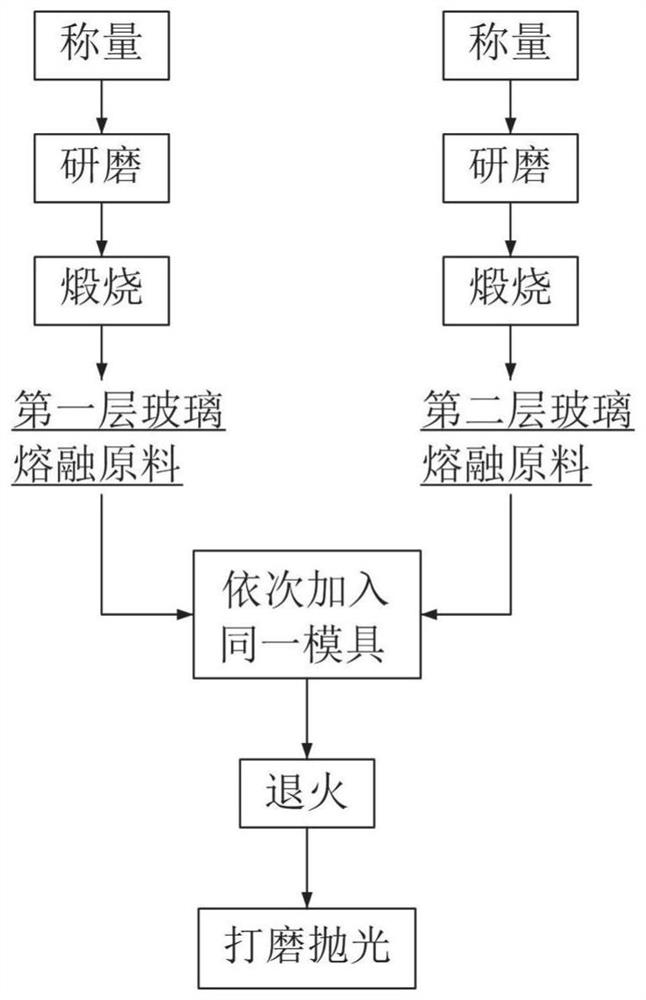

[0068] The rare earth-doped multi-layer luminescent glass with full coverage in the near-infrared band is prepared by the following method, and the process flow chart is as follows: figure 1 Shown:

[0069] (1) Weigh each composition raw material (SiO 2 , PbF 2 , YbF 3 , TmF 3 、HoF 3 、ErF 3 ) and the raw materials of the second luminescent glass layer (SiO 2 , PbF 2 , NdF 3 ), the weighing of all raw materials ...

Embodiment 2

[0075] A rare-earth-doped multilayer luminescent glass with full coverage in the near-infrared band of the present invention, the multilayer luminescent glass is composed of two layers of luminescent glass layers, wherein the first layer of luminescent glass layer is composed of the following molar ratios:

[0076] SiO 2 : PbF 2 : YbF 3 : TmF 3 :HoF 3 :ErF 3 =50:50:1.5:0.5:0.2:0.15

[0077] The second layer of luminescent glass layer is composed of the following molar ratios of each constituent raw material:

[0078] SiO 2 : PbF 2 :NdF 3 =50:50:0.5.

[0079] The rare earth-doped multi-layer luminescent glass with full coverage in the near-infrared band is prepared by the following method, and the process flow chart is as follows: figure 1 Shown:

[0080] (1) Weigh each composition raw material (SiO 2 , PbF 2 , YbF 3 , TmF 3 、HoF 3 、ErF 3 ) and the raw materials of the second luminescent glass layer (SiO 2 , PbF 2 , NdF 3 ), the weighing of all raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com