Super-leaching device and method

A leaching and super technology, applied in the direction of improving process efficiency, etc., to achieve the effect of high leaching rate, easy control and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

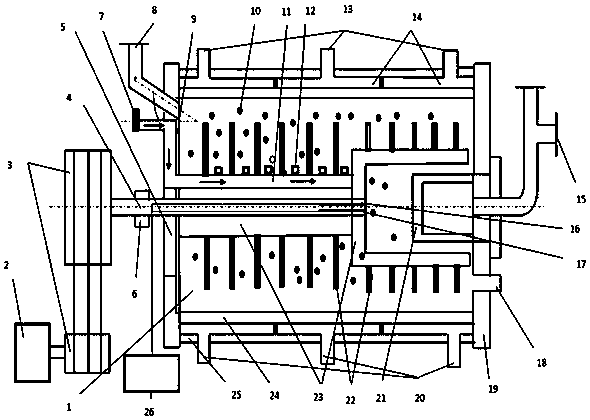

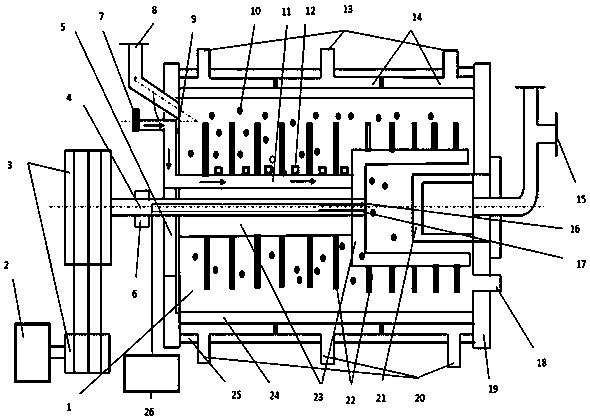

[0048] refer to figure 1 , the super leaching device of this embodiment includes a super leaching chamber 1, an activation structure, a ventilation structure, a temperature control structure and a control structure;

[0049] The super-immersion cavity 1 includes an outer jacket 25 and an inner jacket 24, and a segmented hollow 14 is arranged between the outer jacket 25 and the inner jacket 24. The segmented hollow 14 is used as a circulating water pipeline, and a circulating water pipe is respectively provided. Inlet 20 and circulating water outlet 13, the two ends of described outer cover 25 and inner cover 24 are respectively provided with end cover 19, and the end cover 19 of one end is provided with feed pipe 8 and liner 9, and the end cover 19 of other end is provided with Filter screen 21, discharge pipe 15 and medium discharge port 18; the liner 9 is used to prevent material from flowing backward;

[0050] The activation structure includes a shaft 4, a shaft power inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com