Gas-liquid separator

A technology of gas-liquid separator and separation chamber, which is applied in refrigeration and liquefaction, compressors, refrigeration components, etc., and can solve the problems of the third gas-liquid separator, such as the need to improve efficiency, compactness and low space utilization, and ejector Entrainment effect is not strong and other problems, to achieve the effect of improving gas kinetic energy and ejection efficiency, improving space utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

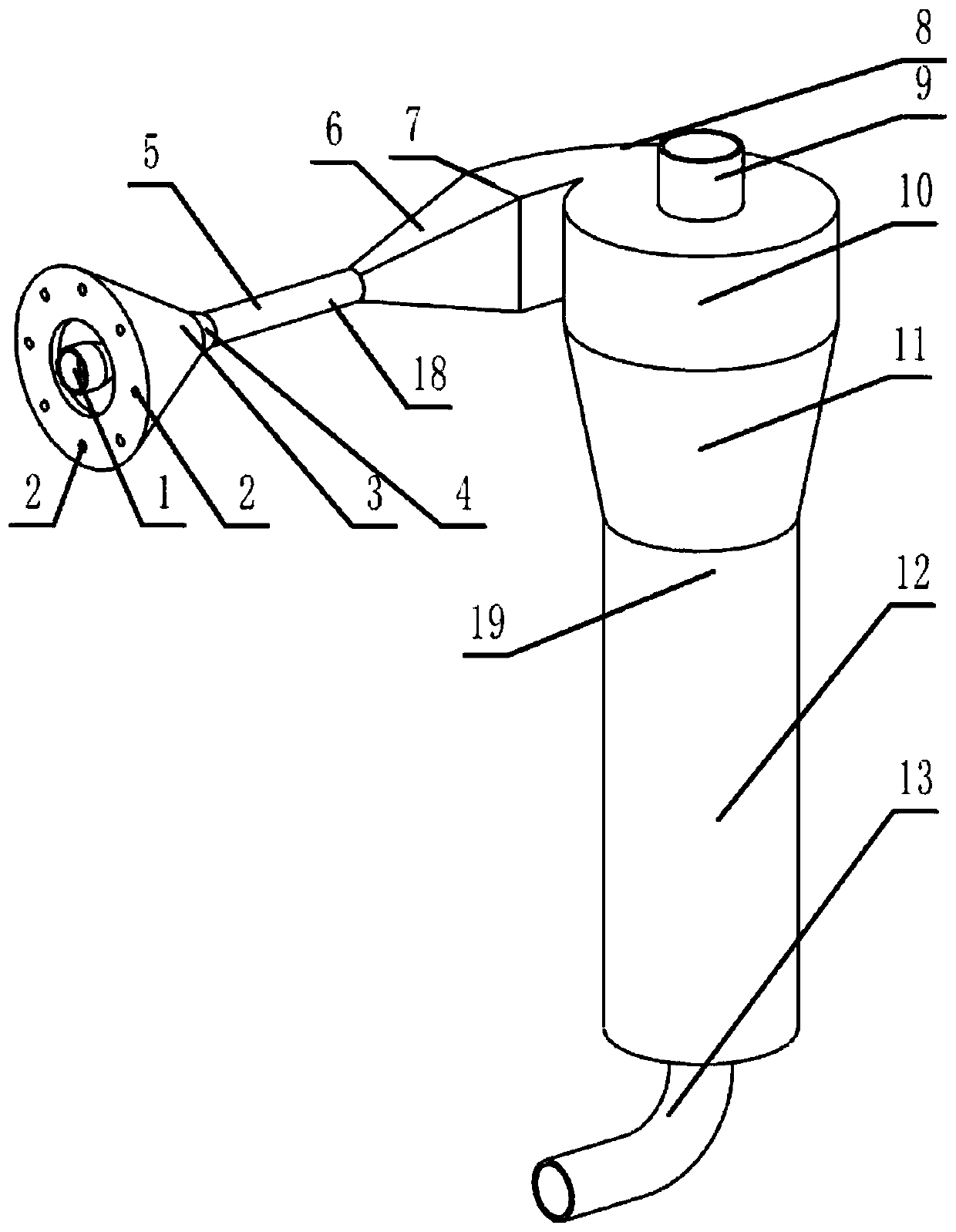

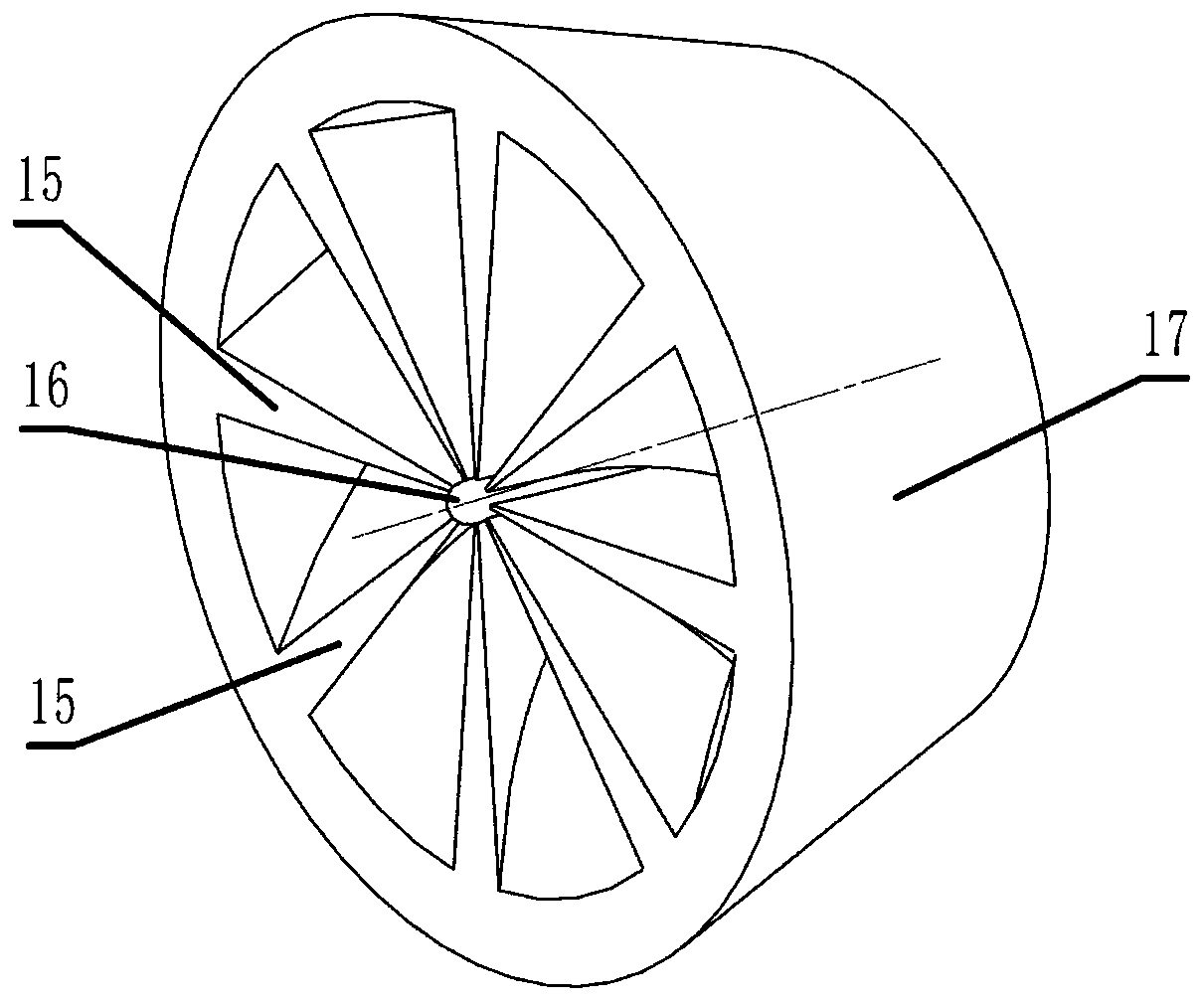

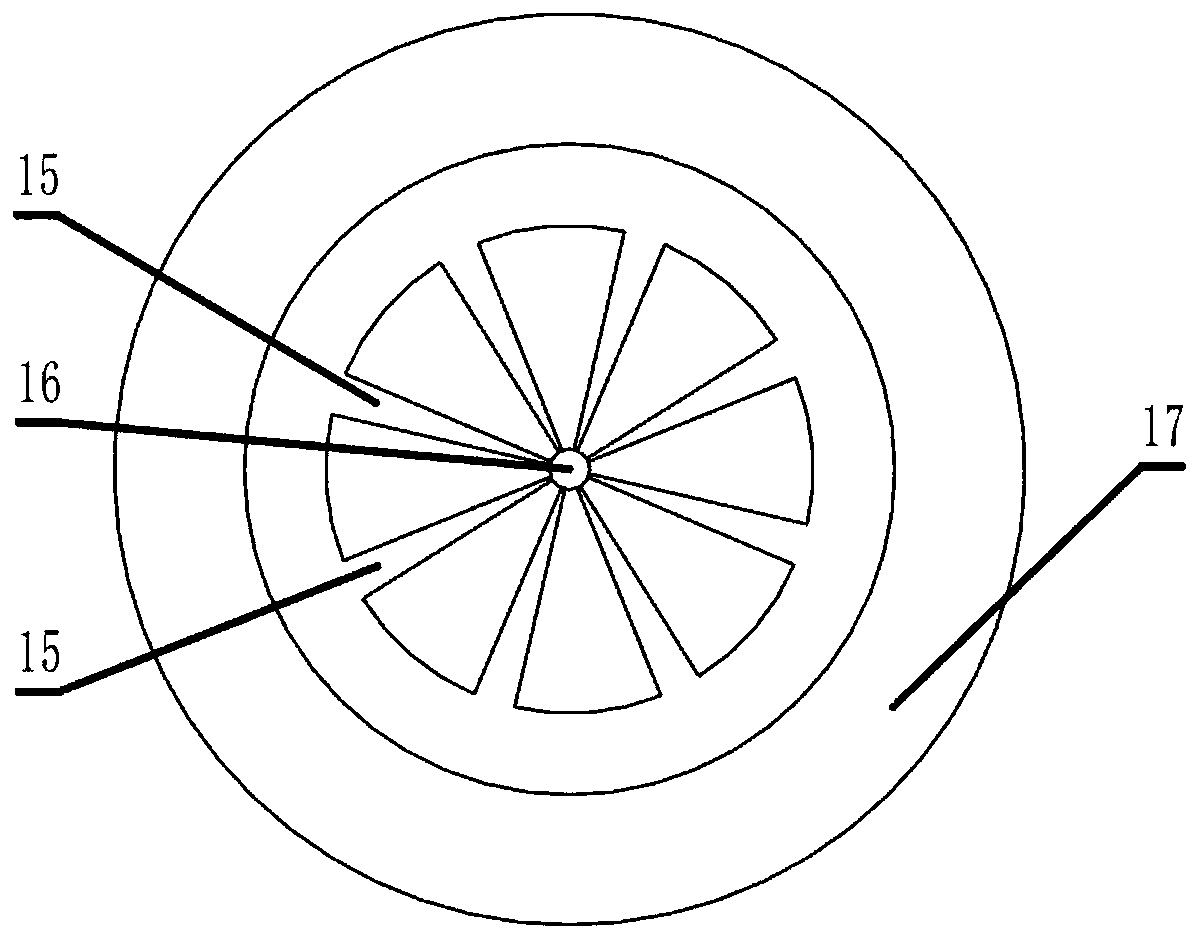

[0024] For the above-mentioned problems to be solved, such as figure 1 As shown, in order to improve the compactness of the system design and the space utilization rate, the present invention combines the injection function with the gas-liquid separator to carry out an integrated design, that is, eight injection holes 2, injection nozzles 14, injection Chamber 3, swirl generator 4, mixing section 5, and diffuser section 6 integrally form the inlet 18 of the gas-liquid separator, the junction of diffuser section 6 and mixing section 5 is circular, and the junction of the other end and pre-swirling section 8 is Rectangular, the design of the pre-swirl section inlet 7 is rectangular to reduce the pressure loss entering the pre-swirl section 8, the gas-liquid mixture obtains a circumferential velocity when flowing through the pre-swirl section 8, and the centrifugal force generated makes the liquid with a large difference in density Separated from the gas, the centrifugal dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com