cumo 2 Preparation method thereof, light-emitting device

A divalent copper and salt solution technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., to achieve the effect of improving carrier mobility, good stability, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The embodiment of the present invention provides a CuMO 2 The preparation method comprises the following steps:

[0019] S01. provide divalent cupric salt solution, under inert atmosphere, add reducing agent in described divalent cupric salt solution, the cupric ion in described divalent cupric salt generates cuprous ion under the effect of reducing agent, obtains copper ion solution;

[0020] S02. provide a M salt solution, the M is selected from one of Ga, In, Cr, Al, and the pH of the M salt solution is 5-6.5; under an inert atmosphere, the M salt solution is added into the cuprous ion solution, the heating reaction generates CuMO 2 .

[0021] CuMO provided by the embodiments of the present invention 2 According to the preparation method, the solution method is adopted to reduce the divalent cupric ions to cuprous ions, and then mix and react with the M salt aqueous solution to prepare CuMO 2 . The reaction conditions of this method are mild, and the prepared C...

Embodiment approach

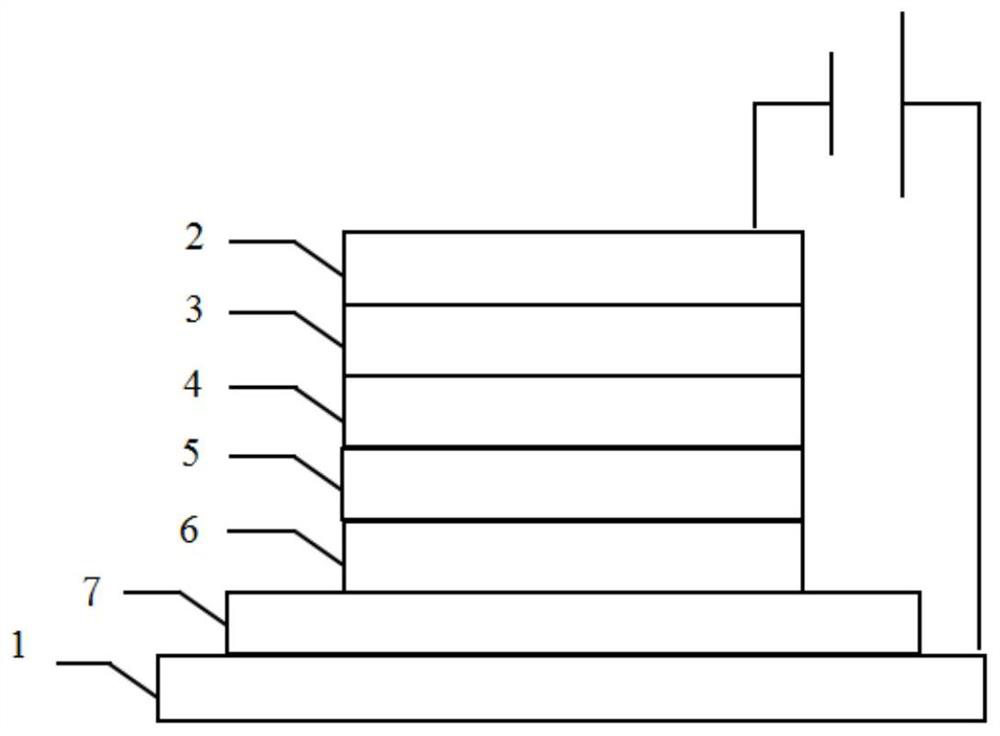

[0044] As an embodiment, the preparation method of the QLED device includes the following steps:

[0045] E01. Provide an anode substrate, and prepare a hole injection layer on the anode substrate in turn;

[0046] E02. Depositing CuMO on the hole injection layer 2 , to prepare a hole transport layer;

[0047] E03. A quantum dot light-emitting layer, an electron transport layer and a cathode are sequentially prepared on the hole transport layer.

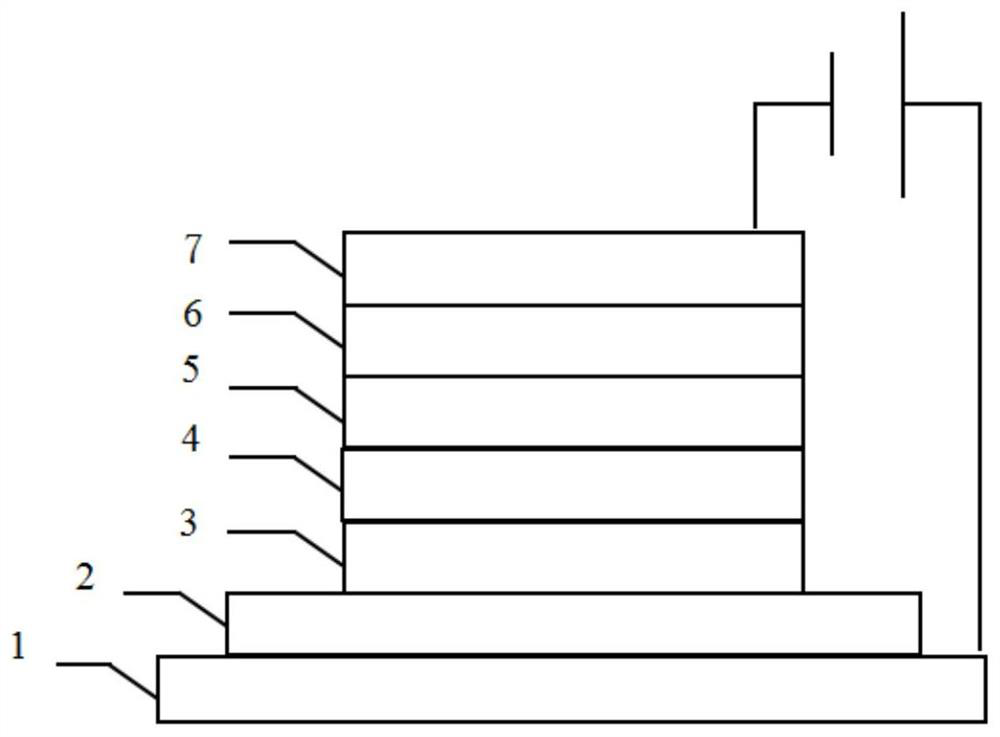

[0048] As another embodiment, the preparation method of the QLED device includes the following steps:

[0049] Q01. Provide a cathode substrate, and prepare an electron transport layer and a quantum dot light-emitting layer in sequence on the cathode substrate;

[0050] Q02. Prepare a hole transport layer on the quantum dot light-emitting layer;

[0051] Q03. A hole injection layer and an anode are sequentially prepared on the hole transport layer.

[0052] Specifically, in the above two methods, the materials of each layer are ...

Embodiment 1

[0058] A CuMO 2 The preparation method comprises the following steps:

[0059] Dissolve 5mmol copper chloride into 5ml water to configure copper chloride solution (solution A), pass in inert gas to remove oxygen dissolved in the water; then dissolve a weak reducing agent, such as 10mmol sodium thiosulfate into 5ml water to configure a weak reducing agent Solution (B solution), pass inert gas to exclude oxygen. Dissolve 5 mmol of gallium chloride into 5 ml of aqueous solution, adjust its pH to 5-6.5, configure C solution, and pass it into a large amount of inert gas to exclude dissolved oxygen in the water.

[0060] Add solution B to solution A and stir the reaction, so that divalent copper is reduced to monovalent copper, and after the reaction is complete; then add solution C, and stir well. Then, the obtained mixed solution was added to the reaction kettle, heated at 200°C for 2 hours, and finally the precipitate obtained by the reaction was washed with ammonia water, nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com