Dual-PWM variable frequency power supply feedback energy processing device and method

A variable frequency power supply and energy processing technology, which is applied to output power conversion devices, electrical components, and AC power input to AC power output. To achieve the effect of low cost, avoidance of failure, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

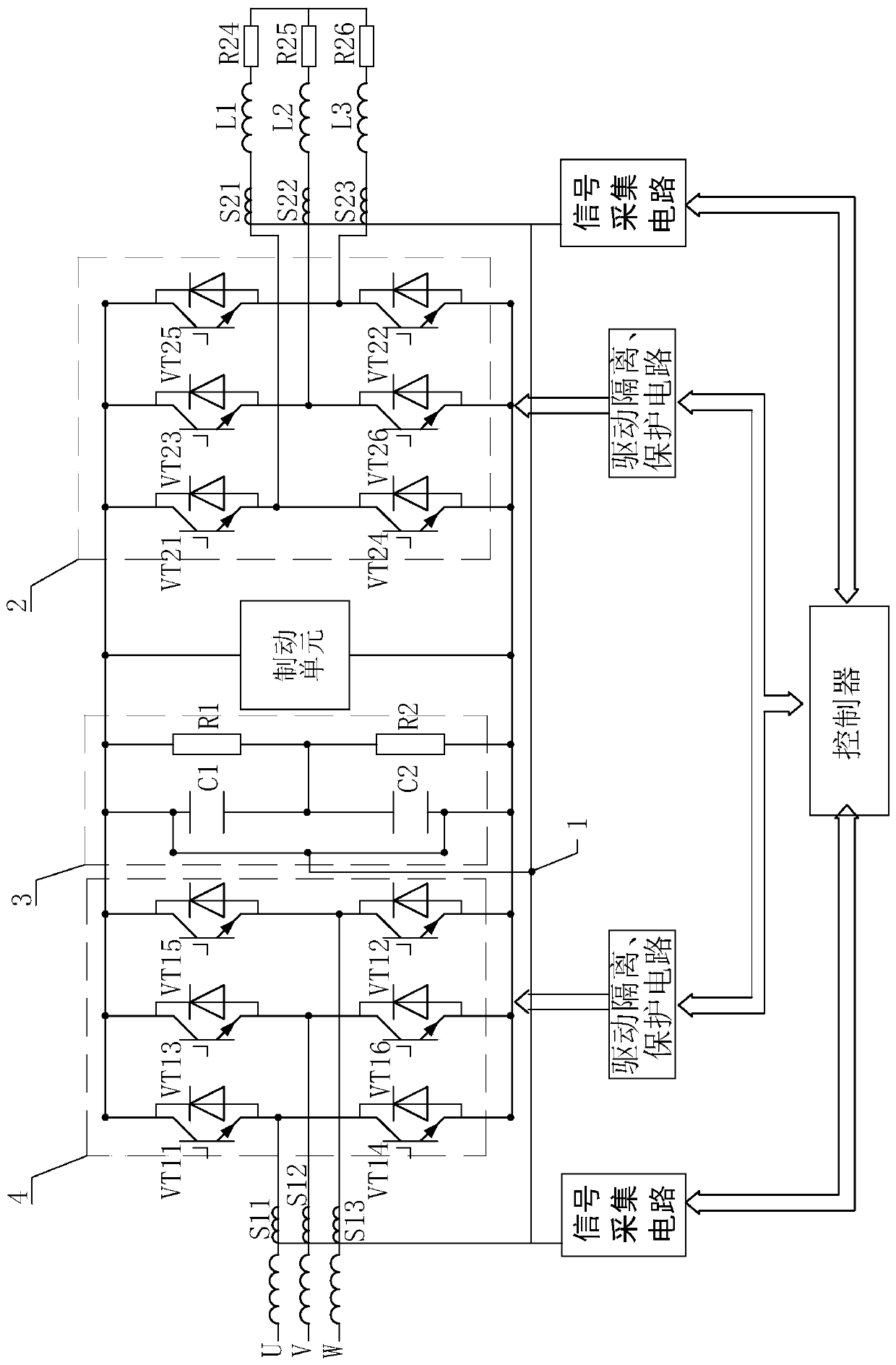

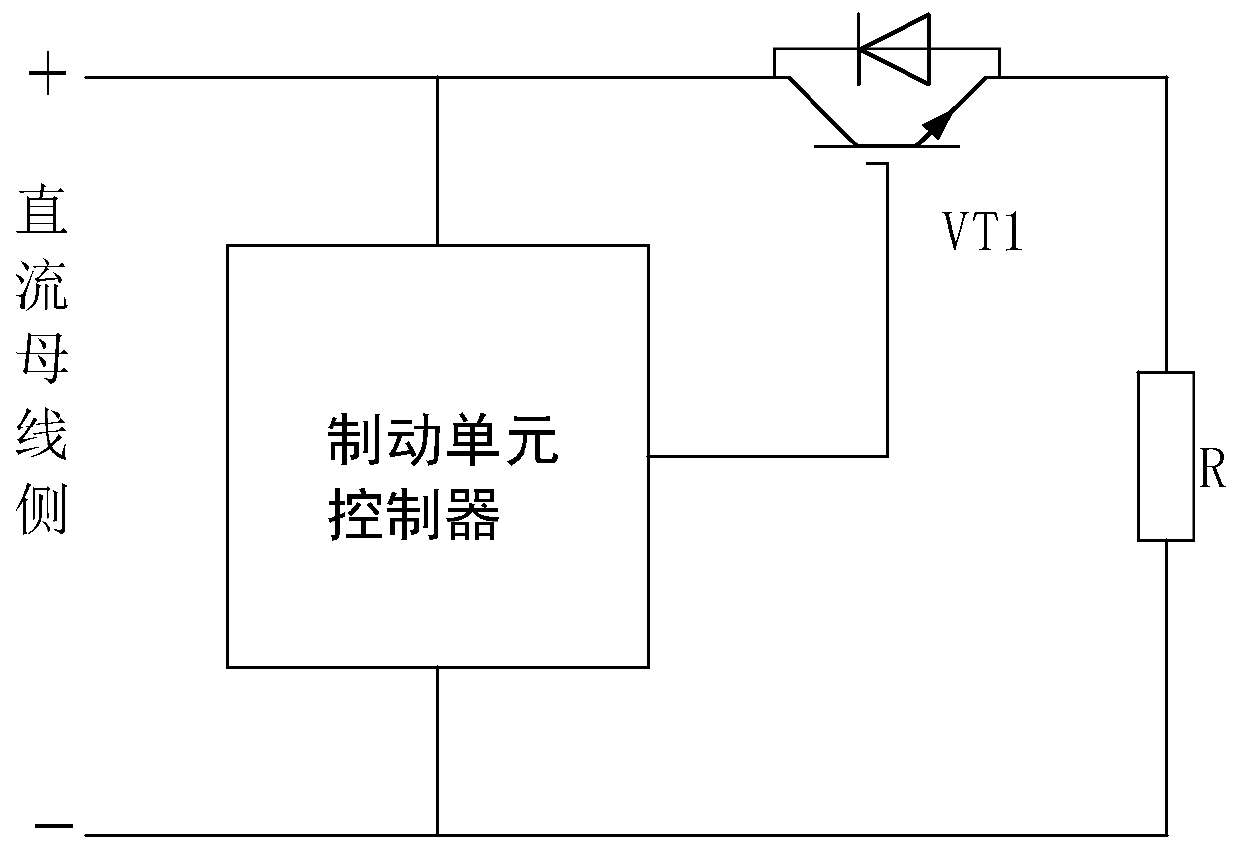

[0036] Such as figure 1 , figure 2 with image 3 As shown, a dual PWM variable frequency power supply feedback energy processing device. The variable frequency power supply includes a PWM rectifier 4, an intermediate link 3, a PWM inverter 2 and a controller. In this example, the controller is a DSP controller, preferably TMS320F28335; the controllers are respectively The drive isolation and protection circuit is electrically connected to the PWM rectifier 4 and the PWM inverter 2. The drive circuit includes an IGBT drive circuit composed of IR2110 chips. The input end of the drive circuit is connected to the controller, and the output end is connected to the PWM rectifier 4 and the PWM inverter. 2; Intermediate link 3 includes two serially connected DC bus capacitors C1 and C2, a voltage equalizing resistor R1 connected in parallel with C1, and a voltage equalizing resistor R2 connected in parallel with C2.

[0037] The processing device of the present invention includes a signa...

Embodiment 2

[0047] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the dual PWM variable frequency power supply feedback energy processing method is applied to the dual PWM variable frequency power supply. The variable frequency power supply includes a PWM rectifier 4 and an intermediate link 3. The two ends of the intermediate link 3 are connected in parallel with a braking resistor R for consuming the feedback energy.

[0048] The processing method includes the following steps:

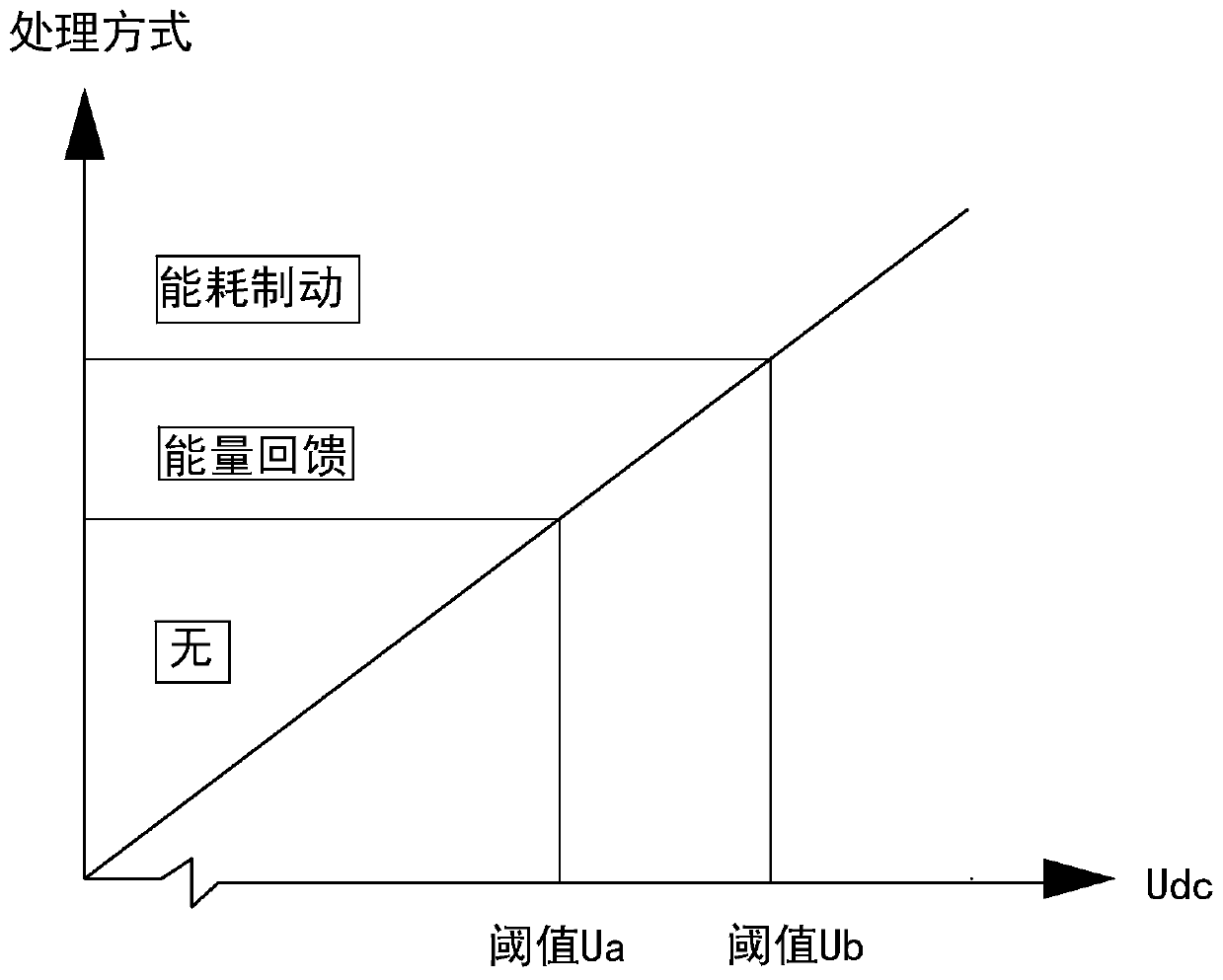

[0049] Step S1: Obtain the DC bus voltage. In this example, the ADC signal acquisition circuit collects the voltage at the connection point 1 of the two series-connected DC bus capacitors. Other methods can be used for acquisition;

[0050] Step S2: Determine whether the DC bus voltage matches the set threshold Ua and / or threshold Ub;

[0051] Step S3. If yes, generate a corresponding control signal;

[0052] Step S4: Control the PWM rectifier 4 to switch between the rectification and active inverter st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com