Hoop reinforcements for tires of heavy civil engineering vehicles

A technology for heavy-duty vehicles and crown reinforcements, which is applied in the field of tire crown reinforcements, and can solve the problems of negative impact on tire manufacturing costs, material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

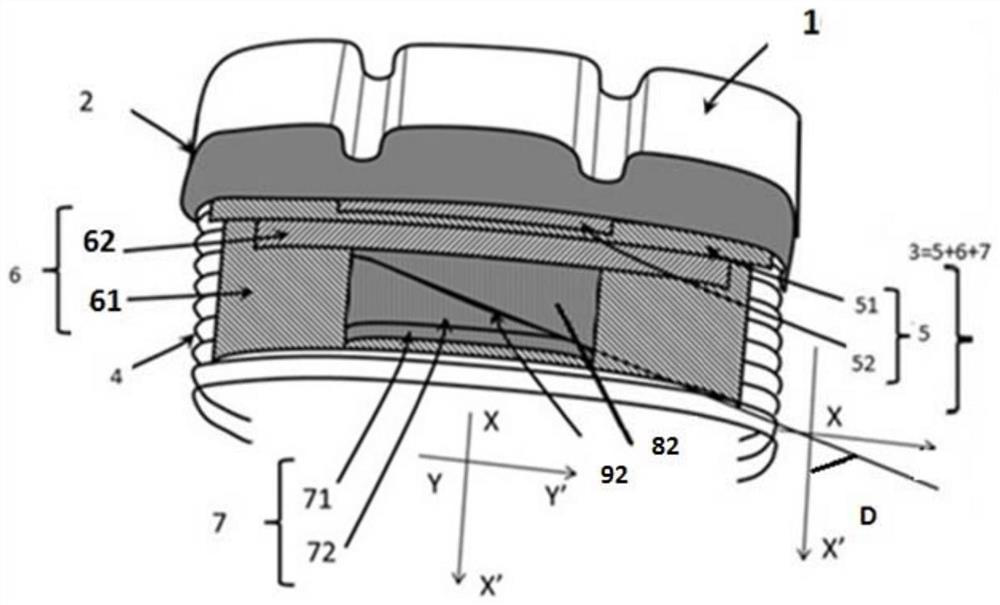

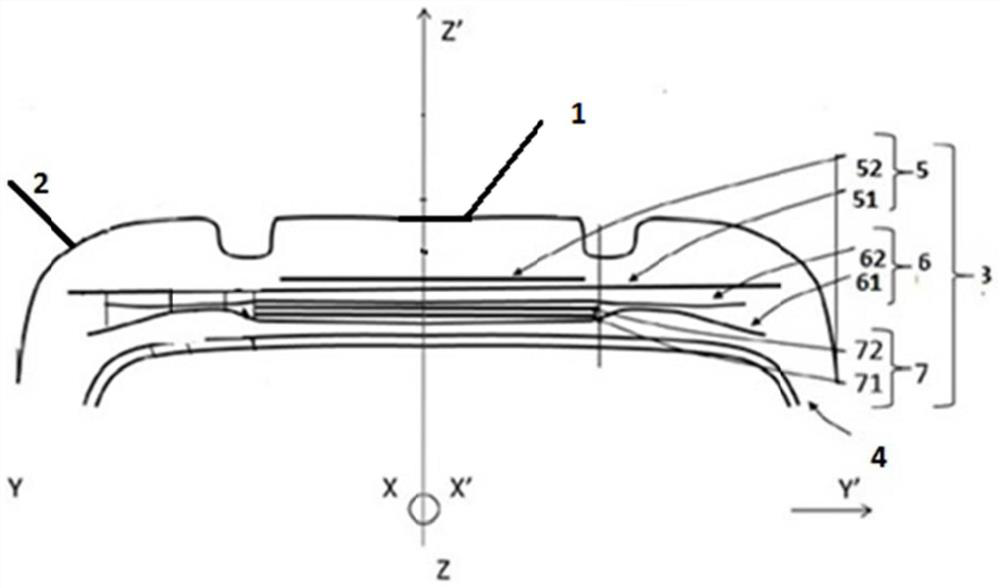

[0064] figure 1 Shown is a cutaway perspective view of a tire crown 1 according to the prior art, said tire crown 1 having:

[0065] - a tread 2 radially outside the carcass reinforcement 4,

[0066] - a crown reinforcement 3 comprising a protective reinforcement 5, a working reinforcement 6 and a hoop reinforcement 7,

[0067] - said protective reinforcement 5 is located radially outermost of the crown reinforcement 3 and comprises two protective layers (51, 52), each protective layer (51, 52) comprising a metallic reinforcement, said metallic reinforcement forming an angle at least equal to 10° with the circumferential direction (XX') which is tangent to the tire circumference,

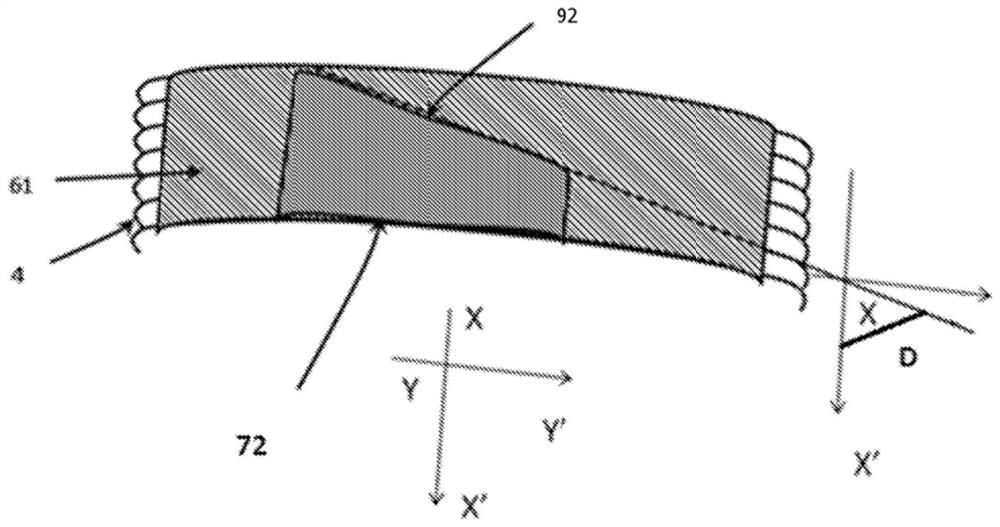

[0068] - said working reinforcement 6 comprises two working layers (61, 62), each working layer (61, 62) comprising a metal reinforcement forming at least equal to 15° with the circumferential direction (XX') while at most an angle equal to 45° and one working layer intersects the next,

[0069...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com