All-wheel system for an electric vehicle and method for operating an all-wheel system of such a vehicle

A technology for motor vehicles and driving axles, which is applied in electric vehicles, electrical devices, vehicle components, etc., and can solve problems such as speed disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

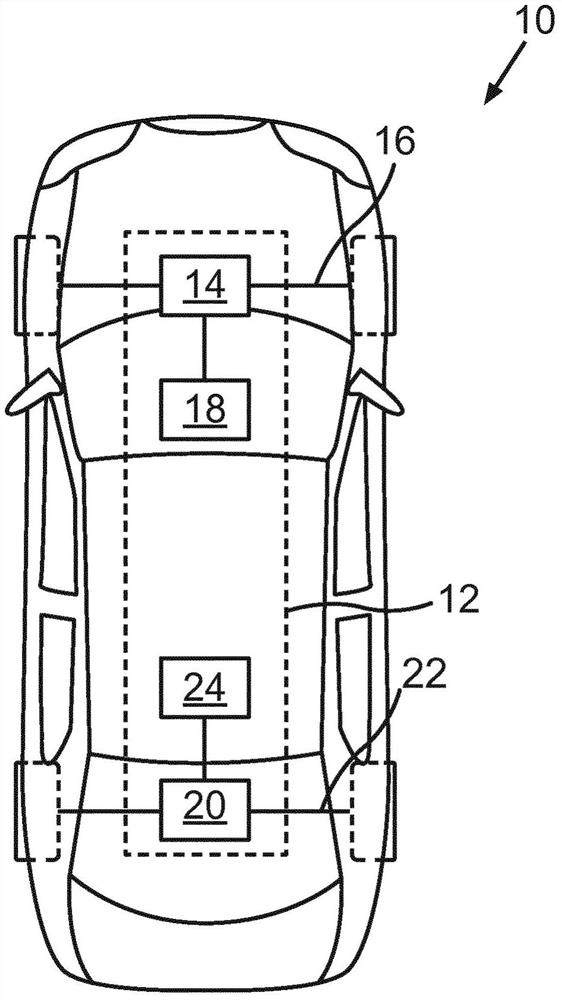

[0025] in the only attached figure 1 A schematic diagram of a motor vehicle 10 with an all-wheel system 12 is shown in . The motor vehicle 10 shown here is an electrically driven motor vehicle. All-wheel system 12 includes a first electric machine 14 for driving a first axle 16 of motor vehicle 10 . All-wheel system 12 also includes first power electronics 18 for controlling first drive motor 14 of motor vehicle 10 . All-wheel system 12 also includes a second electric machine 20 for driving a second drive axle 22 of motor vehicle 10 . The all-wheel system 12 also includes a second power electronics system 24 for controlling the second electric machine 20 .

[0026]The two electric machines 14 , 20 are fed with electrical energy by means of a traction battery (not shown here). The maximum power of the electric machines 14 , 20 is preferably equal to the maximum outputtable electrical power of the power battery (not shown here). If a traction battery (not shown here) can ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com