One-time coloring premixing agent with mica powder wrapped by pearly-luster coating and manufacturing method

A technology of mica powder and premix, which is used in pharmaceutical formulations, food ingredients as colors, and medical preparations with non-active ingredients, etc., can solve the problems that consumers mistaken for fake products, inconsistent product vision, and high coloring requirements. , to achieve the effect of increasing moisture resistance, uniform color, and guaranteed color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

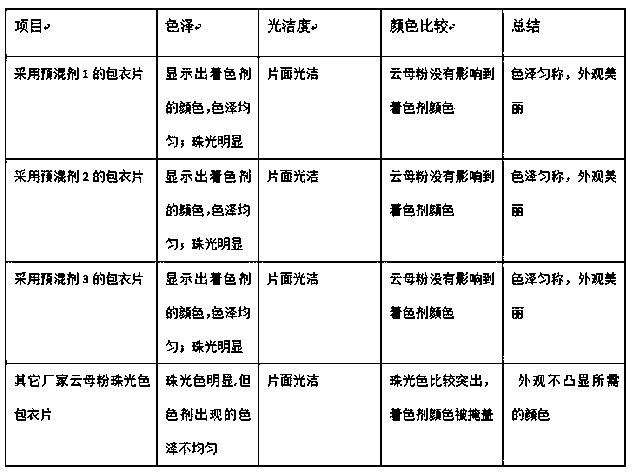

Examples

Embodiment Construction

[0021] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

[0022] The hypromellose in this application can be the hypromellose that is maturely used in film coating at present, and there is no special requirement for it in this application.

[0023] Premix 1 for this application:

[0024] Adopt the following weight ratio, coloring agent adopts pigment,

[0025] Hypromellose: 50 parts

[0026] Mica powder: 15 parts

[0027] Colorant: 15 parts

[0028] Triacetin: 8 servings

[0029] Tween 80: 6 servings

[0030] Castor oil: 6 parts;

[0031] Premix 2 for this application:

[0032] Adopt the following weight ratio, coloring agent adopts pigment,

[0033] Hypromellose: 48 parts

[0034] Mica powder: 14 parts

[0035] Colorant: 16 parts

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com