Low-consumption thermal circulation type glass processing kiln furnace

A technology of heat consumption and glass, which is applied in the field of low heat consumption cycle glass processing furnaces, can solve the problems of affecting processing efficiency, increasing processing cost, affecting service life, etc., and achieves the goals of shortening processing time, prolonging service life and increasing combustion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

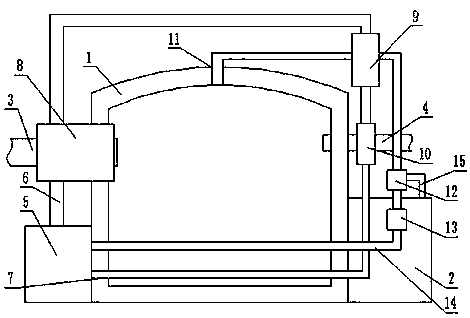

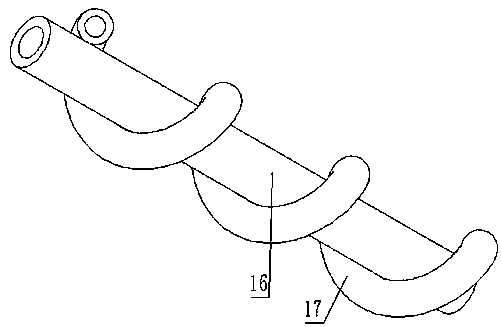

[0018] see Figure 1-2 , a low-heat-consumption cycle glass processing furnace, comprising a furnace body 1, a feed channel 3 and a gas pipe 4 are respectively arranged on the upper parts of both sides of the furnace body 1, the feed channel 3 is used for conveying raw materials, and the gas pipe 4 is used for The gas is delivered, and the combustion of the gas generates high temperature in the furnace body 1, and the raw materials are melted to form molten glass; the outer side of the furnace body 1 has a water tank 5 and a working pool 2 arranged in parallel with it, and the working pool 2 is used to draw out the melted glass, and the water tank 5 stores heat exchange water, the water tank 5 and the working pool 2 are located on both sides of the furnace body 1, the top of the water tank 5 is provided with a water outlet pipe 6, and a second heat exchanger 9 is arranged on the water outlet pipe 6, and the feed channel 3 and The first heat exchanger 8 and the third heat excha...

Embodiment 2

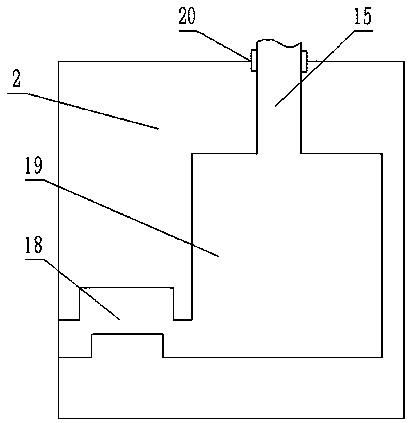

[0021] refer to image 3 , on the basis of Embodiment 1, the working pool 2 has a storage cavity 19, the lower part of the side of the storage cavity 19 is provided with a stepped passage 18 communicating with it, and the other end of the stepped passage 18 is connected to the inside of the furnace body 1, and the stepped passage 18 is used. In order to introduce the molten glass in the furnace body 1 into the storage chamber 19, the curved stepped passage 18 is convenient for sealing and blocking to reduce backflow. The top of the storage chamber 19 is provided with a negative pressure tube 15, and the other end of the negative pressure tube 15 is connected to the negative pressure tube 19. The pressure blower 12 is connected together. After the molten glass is melted, the negative pressure blower 12 will also suck out the air in the storage chamber 19 when the glass liquid is melted. The liquid can also discharge the internal air under the action of negative pressure; specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com