Monofilament viscose chenille fabric and production technique thereof

A production process and technology of glue snow, applied in the field of textile fabrics, can solve the problems of decreased comfort, poor nylon hand comfort, limited application scope, etc., and achieve the effects of difficult work efficiency, good warmth retention, and comfortable hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

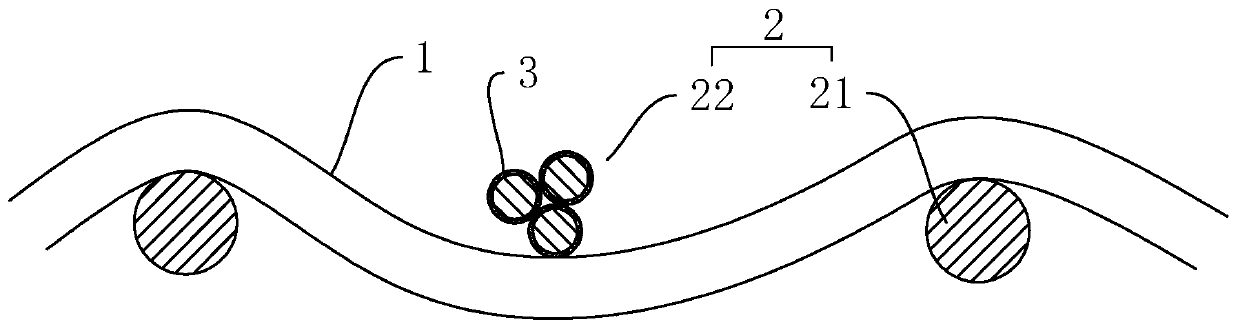

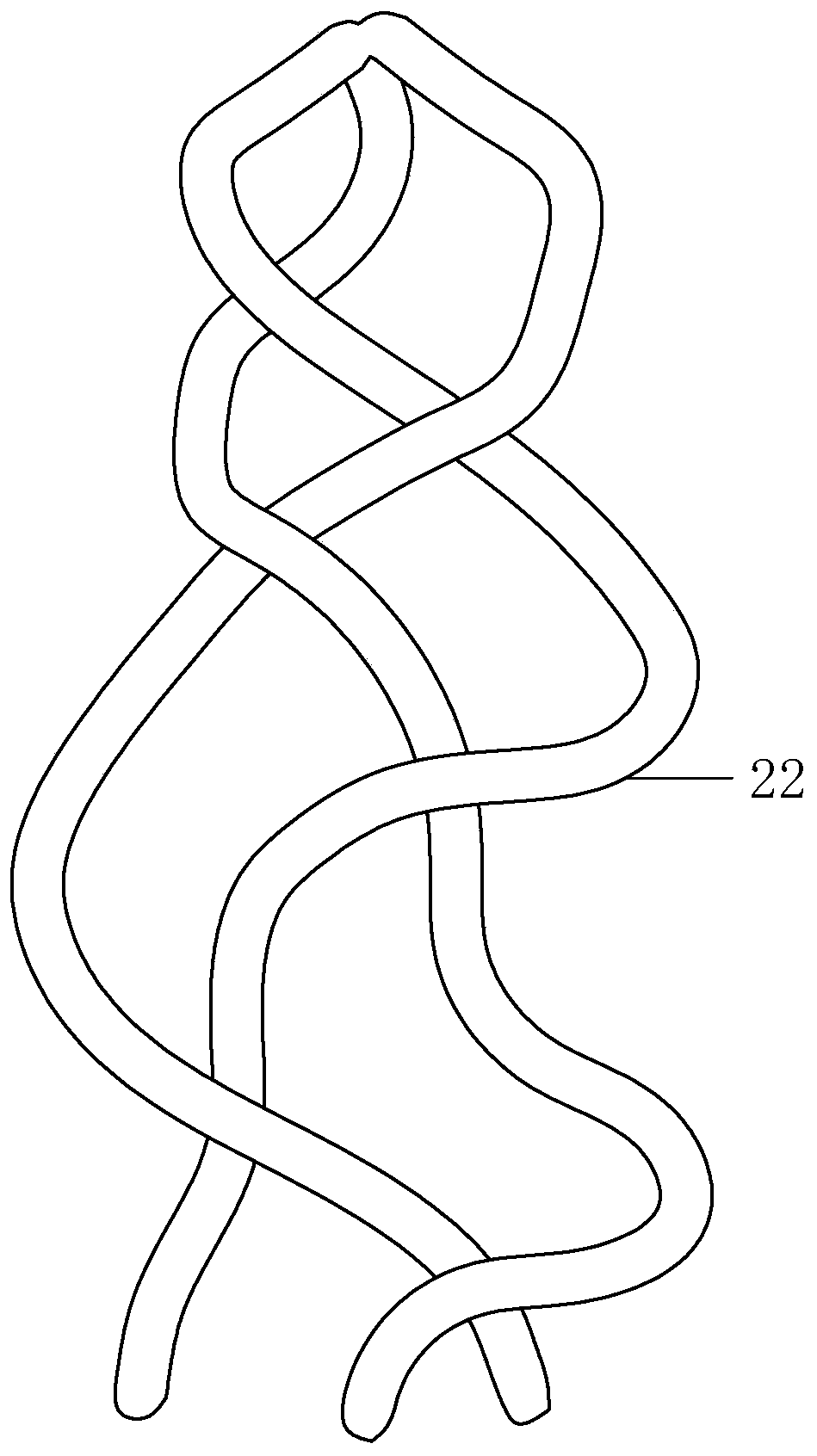

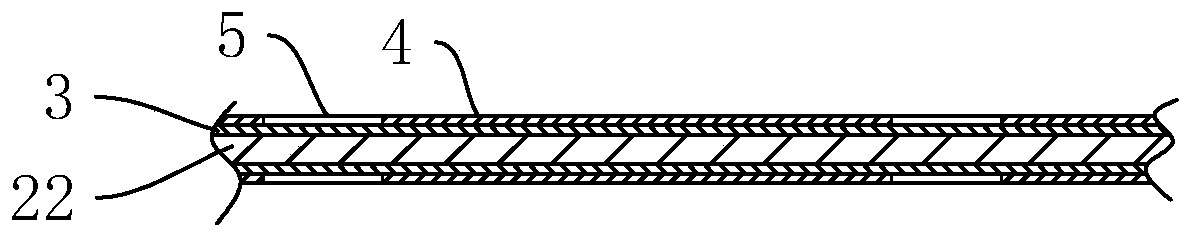

[0040] refer to figure 1 , is a kind of monofilament viscose chenille 22 fabric disclosed by the present invention, comprises base cloth layer, and base cloth layer is woven by air-jet loom by warp thread 1 and weft thread 2, and the total root number of whole piece fabric warp thread 1 is 8000-9000 pieces (specifically 8000 or 8510 or 9000 pieces), the width of the base fabric layer is 160-220cm (specifically 160cm or 185cm or 220cm), and the weft density of the upper machine is 18-20 shuttles / cm (specifically 18 shuttles / cm or 18.5 shuttles / cm or 20 shuttles / cm), the button number is 23# / cm, and the button width is 180-200cm (specifically 180cm or 185cm or 200cm).

[0041] Warp 1 includes 20D nylon semi-gloss monofilament. Nylon semi-gloss monofilament is a product obtained after nylon monofilament is brightened. Nylon monofilament is also called nylon monofilament or polyamide monofilament. It is made of adipic acid and adipic acid. Diamine or caprolactam is a synthetic fi...

Embodiment 2

[0044] A kind of production technology of monofilament viscose chenille fabric, comprises the steps:

[0045] S1 winding: wind the warp and weft yarns into bobbins, and remove defects and impurities;

[0046] S2 warping: winding the warp yarn on the warp beam;

[0047] S3 sizing: put the warp beam on the sizing machine, soak the warp yarn in the size, and dry it in an oven after absorbing the size;

[0048] S4 gluing: before gluing, boil 3 sticks of viscose chenille 22 and add 3-5% soda ash and 4-5% soap of fabric weight, the temperature is controlled at 40-50°C to remove 3 sticks of viscose Impurities and waxy fat on chenille 22, put 3 sticks of viscose chenille 22 on the gluing machine for gluing, before gluing, 3 sticks of viscose chenille 22 are continuously cleaned by circulating water during transportation Spray water on it, put a toughening agent in the glue to facilitate gluing, and blow it through a fan at the same time, and pre-dry it to form the first silica gel l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com