Heat exchange gas-liquid separator with economizer function

A gas-liquid separator and economizer technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc., can solve the problem of not being able to provide high-pressure refrigerant supercooling, save material costs and space, and increase heat transfer The area is conducive to the effect of effective heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

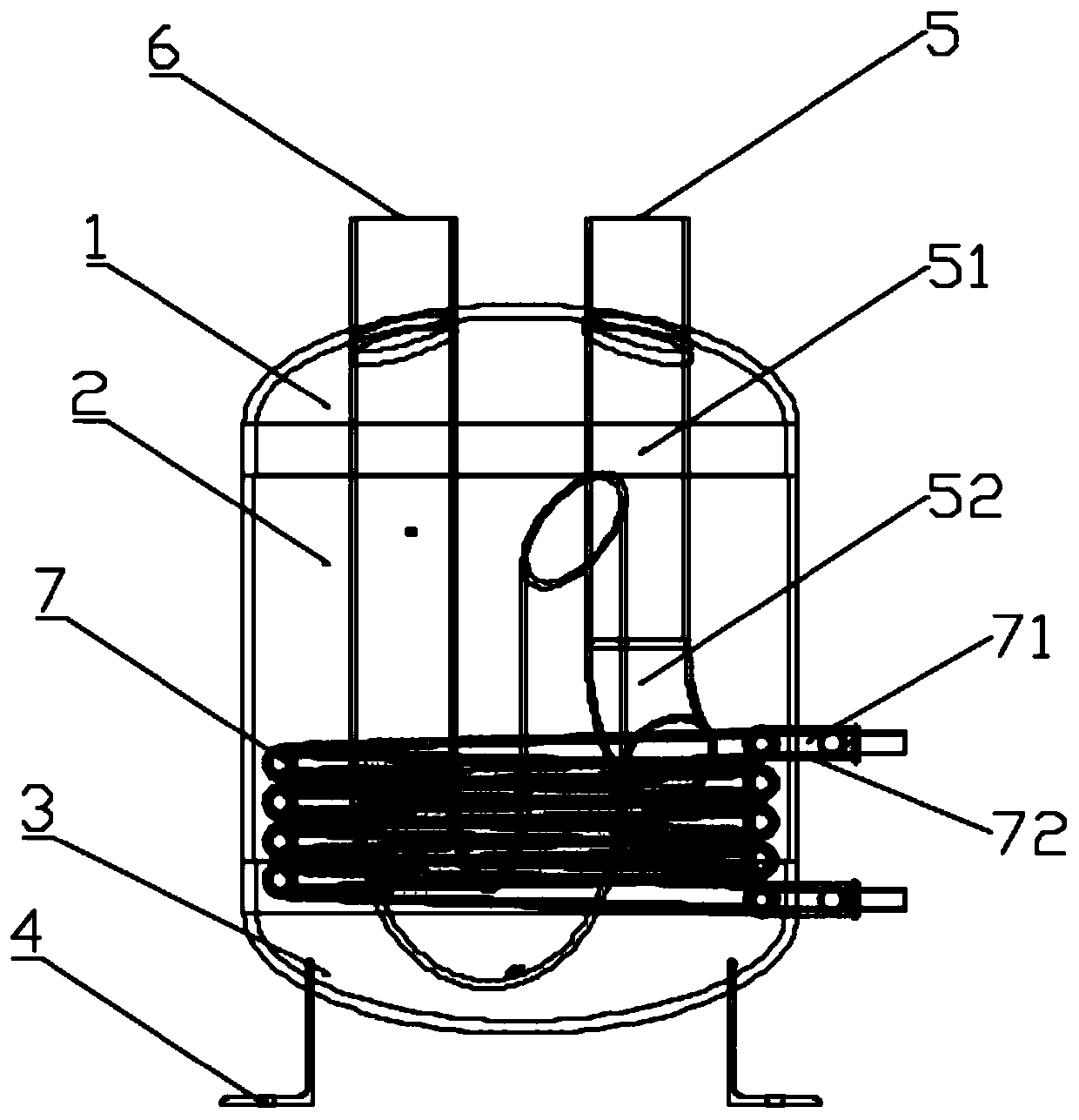

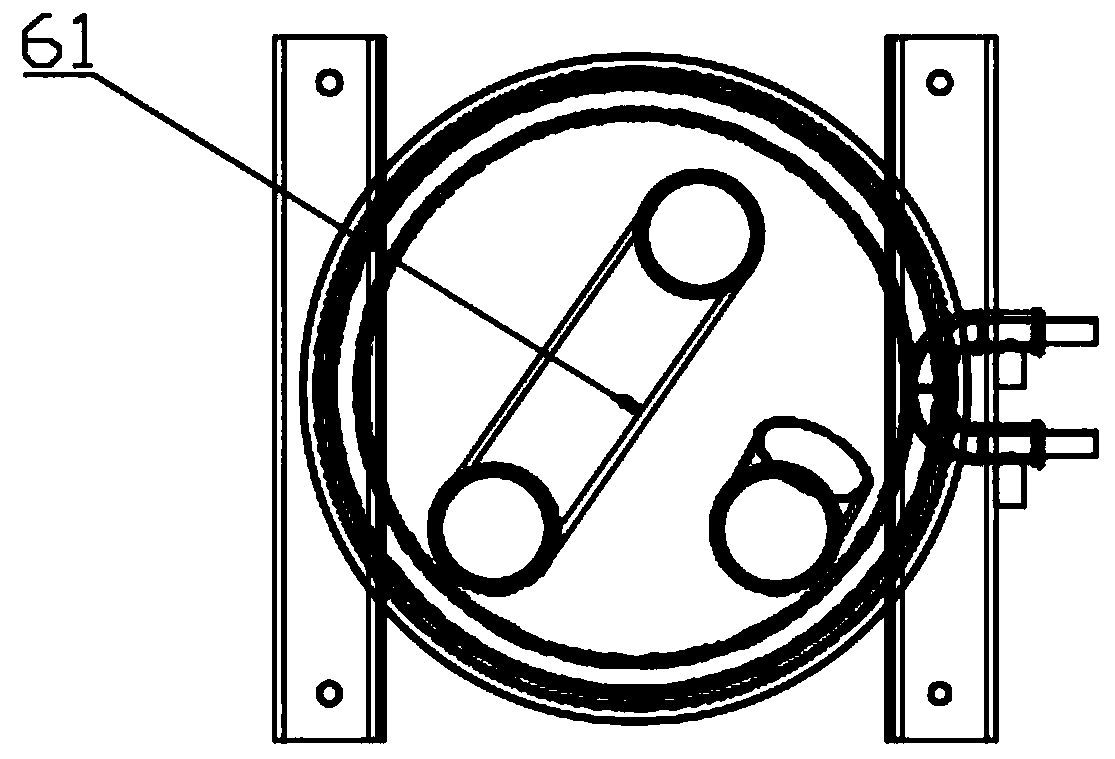

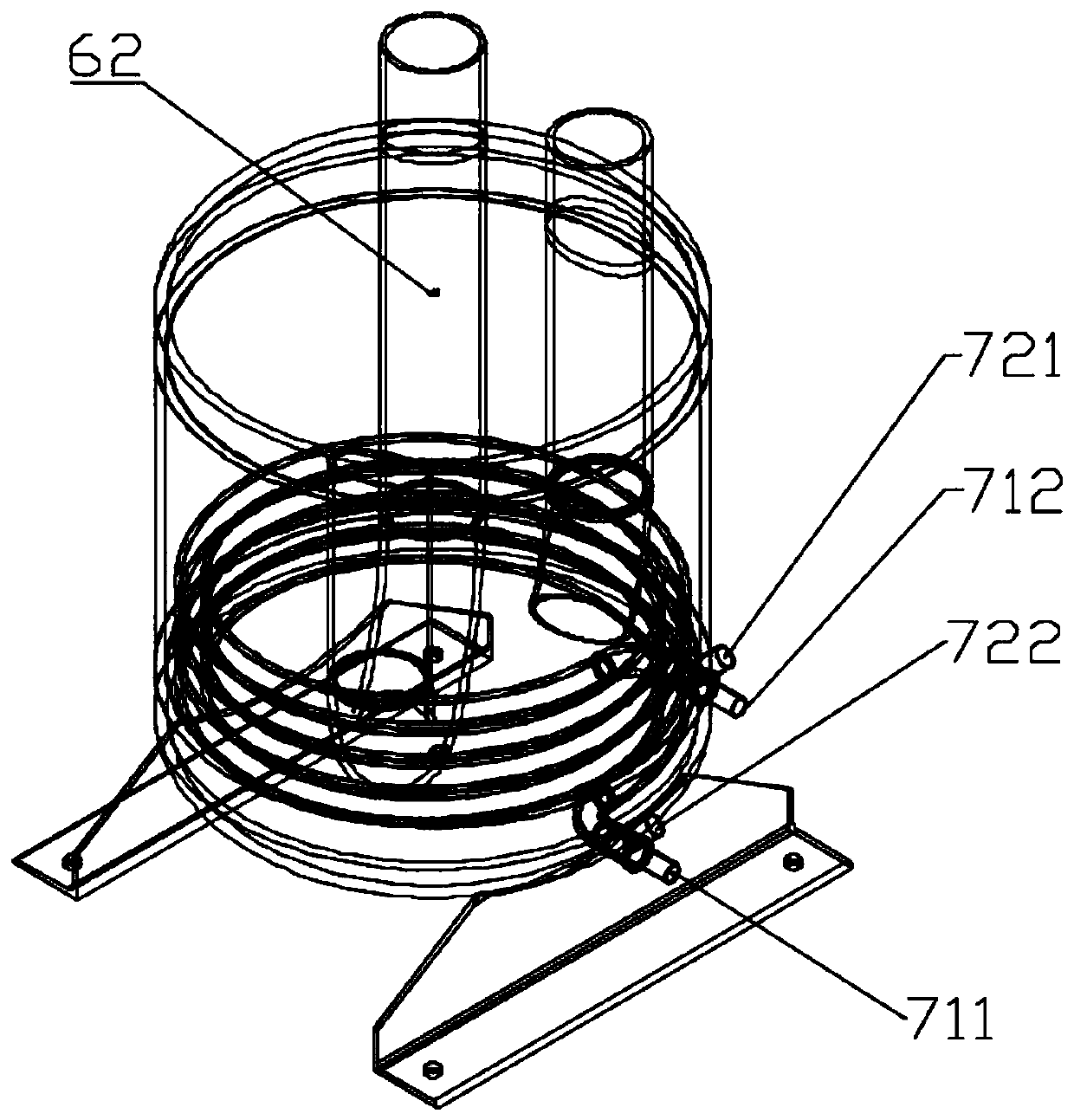

[0021] see figure 1 , figure 2 with image 3 , the heat exchange gas-liquid separator with economizer function in this embodiment includes a cylinder body 2, an upper cover 1 fixedly welded on the upper end of the cylinder body 2, and a lower cover 3 fixedly welded on the lower end of the cylinder body 2. The lower cover 3 is supported so that the cylinder body 2 is kept upright, and the cylinder body 2 is provided with an air inlet pipe 5, an air outlet pipe 6 and a heat exchanger 7; In a sleeve-and-tube heat exchanger composed of outer stacks, the nozzles at both ends of the inner tube 71 are respectively set as a throttling refrigerant inlet 711 and the gaseous refrigerant outlet 712, and the nozzles at both ends of the outer tube 72 are respectively set as a high-pressure liquid refrigerant inlet 721 and The high-pressure liquid refrigerant outlet 722 bypasses a branch of the high-pressure liquid refrigerant circuit, and the refrigerant liquid enters the inner pipe 71 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com