Parallel gradual-loading three-shaft sample making device

A technology of triaxial sample and graded loading, which is applied in the preparation of test samples, etc., can solve the problems of large individual differences in samples, difficulties in making triaxial samples, and inability to accurately reflect the real stress of cement and soil. Achieve the effect of avoiding disturbance and reducing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

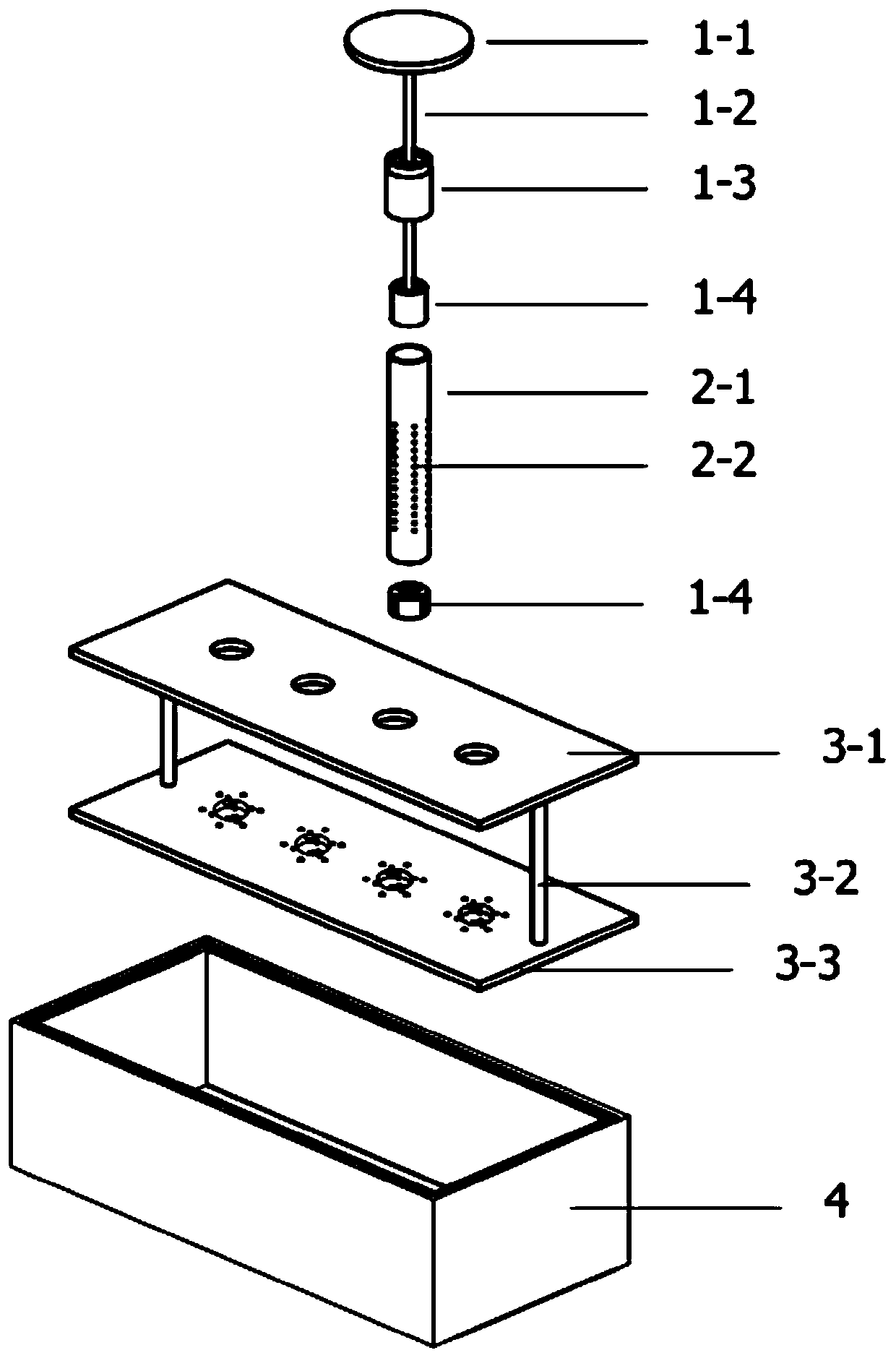

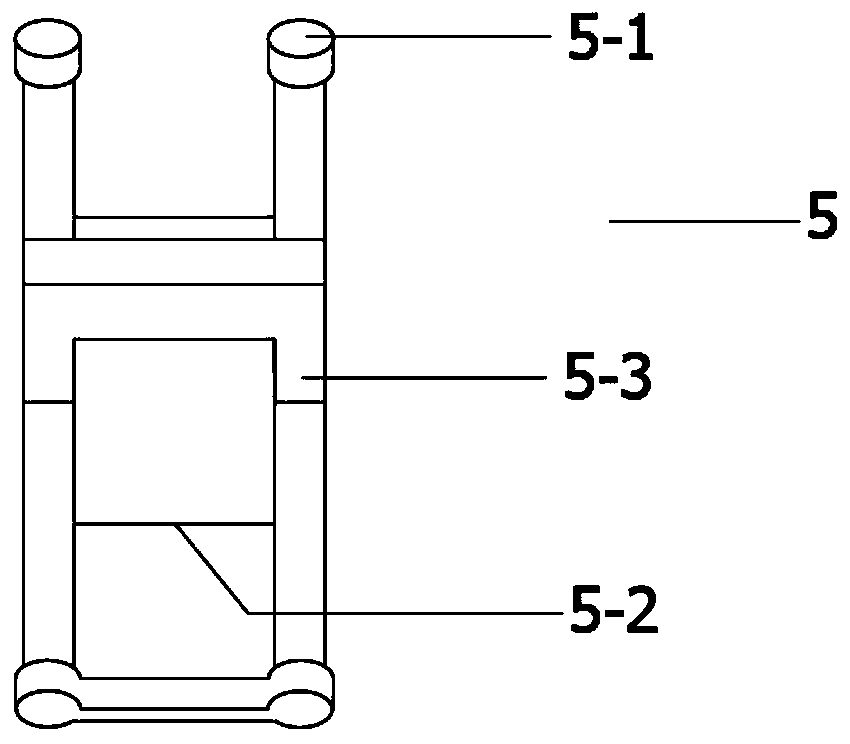

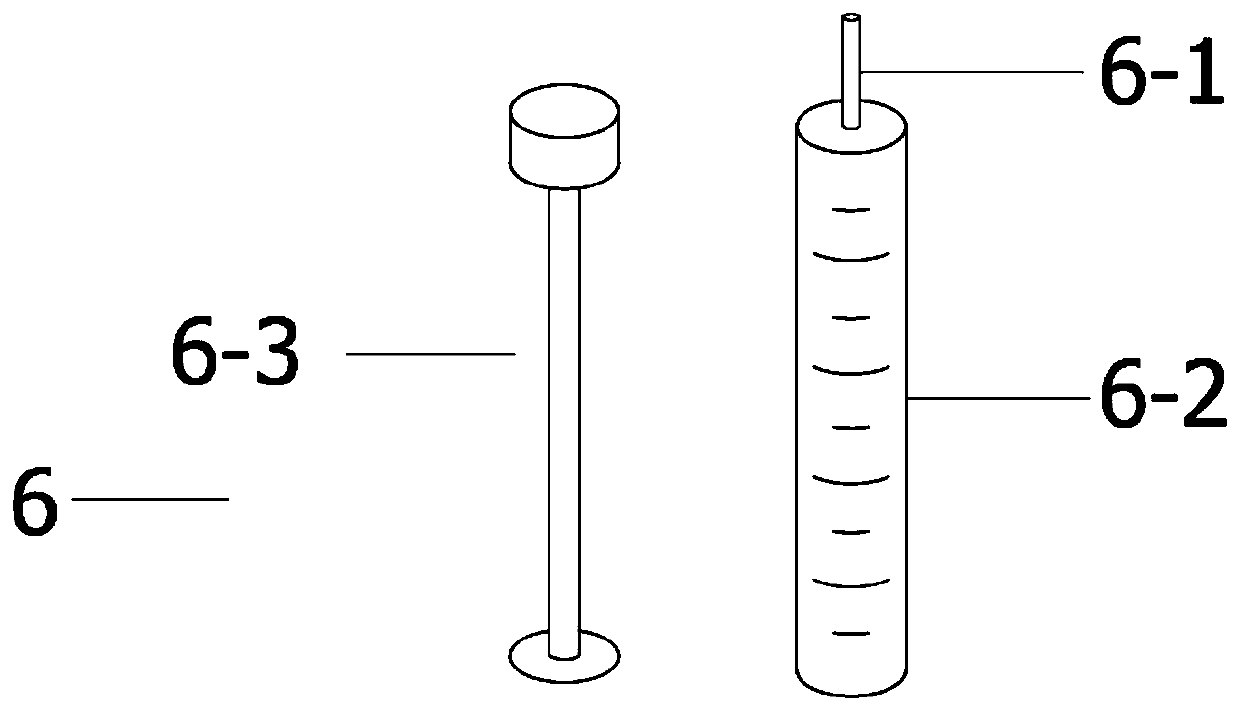

[0042] combine Figure 1-Figure 12 As shown in the figure, a parallel-type hierarchical loading triaxial sample preparation equipment in the present invention includes a pressure applying mechanism 1, a sample bearing mechanism 2, a supporting mechanism 3, a liquid collecting mechanism 4, a cutting mechanism 5, and a soil injector 6 , Three-bearing membrane cylinder 7, ear wash ball 8.

[0043] The load-bearing plate 11 is located at the top, its main body is a circular plate, and the lower part is the force transmission shaft 12 . The pressure fixing cover 13 passes through the force transmission shaft 12 , and there are three circular holes distributed thereon, the center of which is the force transmission shaft hole 131 ; The main body of the pressure disc 14 is a pressure cylinder 141 , which is fixed on the bottom end of the force transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com