A kind of chromatographic reagent distillation recycling method

A technology for distillation recovery and chromatography is applied in the field of a method for distillation recovery and utilization of chromatographic reagents, which can solve the problems of complex structure, cumbersome maintenance and high use cost of a hydrogen flame detector, and achieve a stable and reliable method, simple and economical method, and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

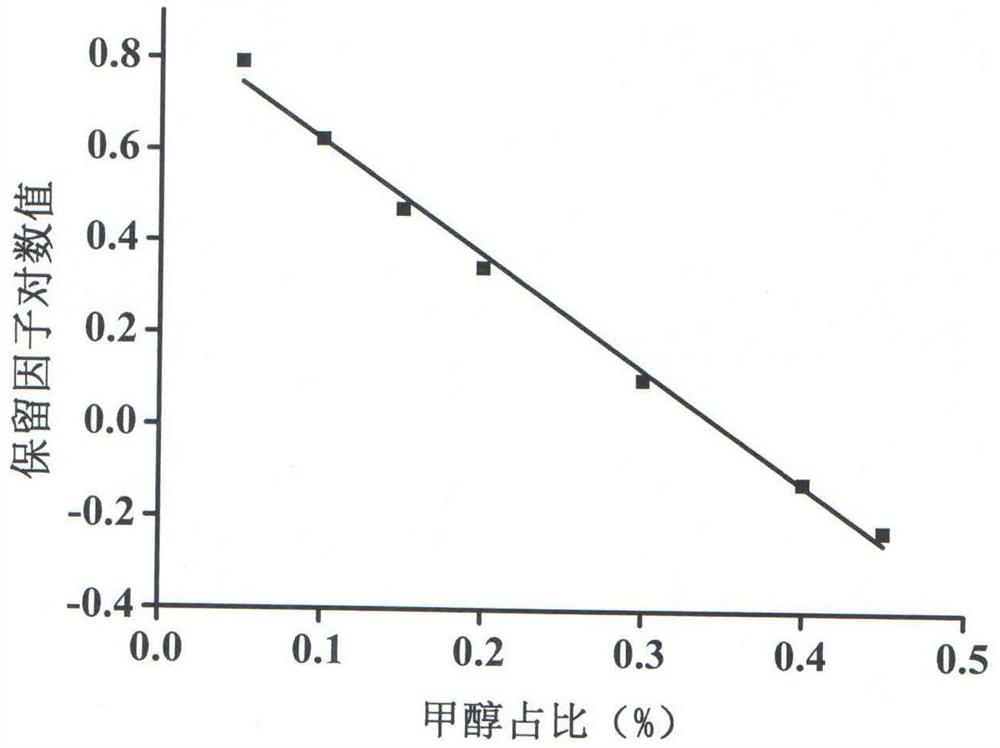

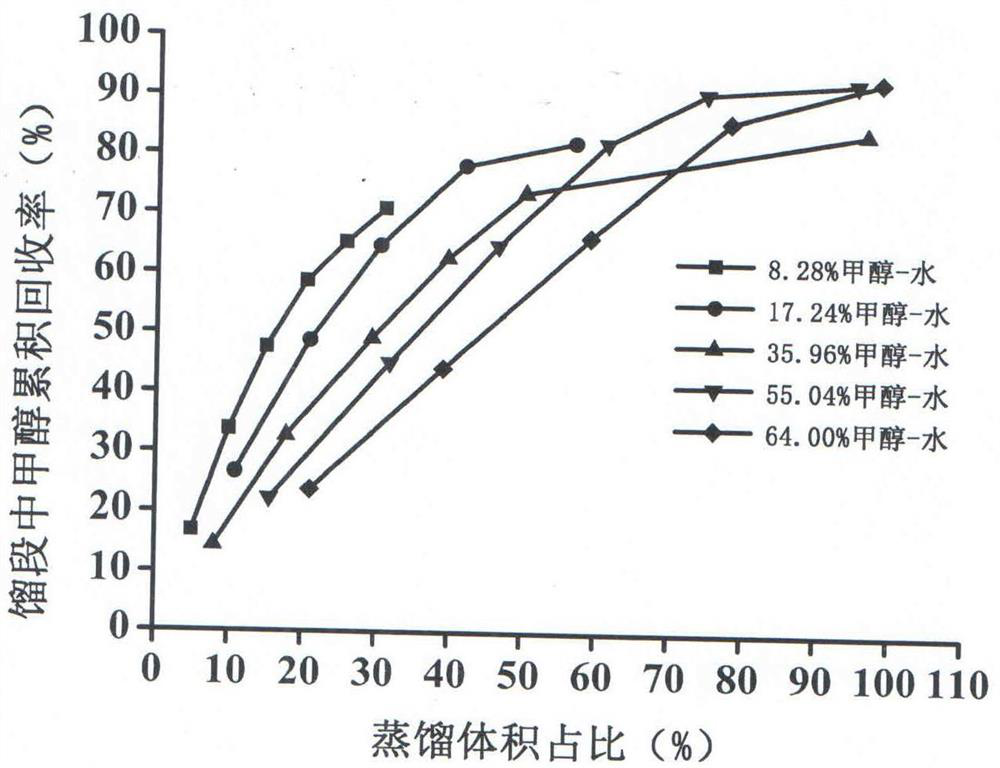

[0036]Based on the linear solvent intensity theory of liquid chromatography, a general reverse column chromatography column is connected to a high-performance liquid chromatograph equipped with a general ultraviolet detector for determination, weigh 10 mg of benzene phenol, add 100 ml. Methanol is prepared into a liquid, the high-performance liquid chromatograph is composed of a double pump, and the pump A is connected to the organic phase, and the pump B is connected to a water solution of 0.1% formic acid. The flow rate of the pump A and the pump B is controlled by the chromatographic workstation (where the total flow rate is 1.0 ml / min), the final mixing became a methanol mass fraction of 4.04, 8.16%, 12.37%, 16.67%, 25.53%, 34.78%, 39.56% methanol-aqueous solution, and equilibrated column for 20 minutes, respectively (column temperature control at 30 ° C), the mixed solution of methanol and 0.1% formic acid is the retention factor K, and the retention factor K is measured un...

Embodiment 2

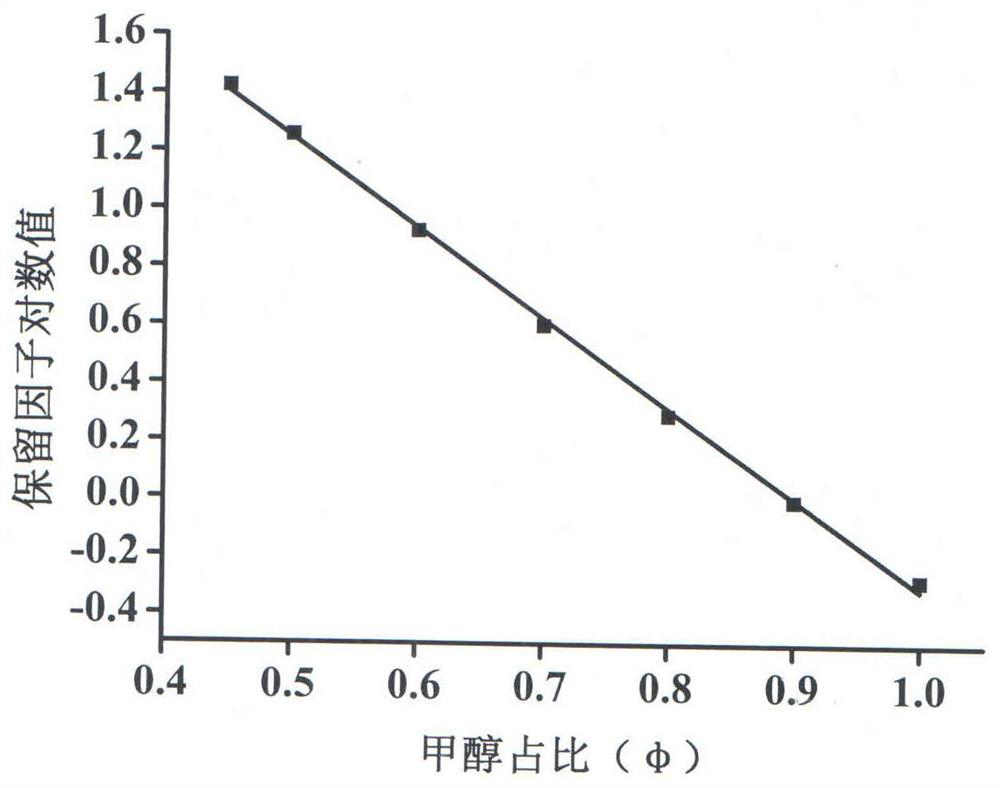

[0043] Based on the linear solvent intensity theory of liquid chromatography, a normal reverse column chromatographic column is connected to a high-performance liquid chromatograph with a general ultraviolet detector for a general ultraviolet detector based on the linear solvent intensity theory of liquid chromatography. Determination, 100 μL of toluene was added to 100 mL of acetonitrile to be prepared to be tested, and the high-efficiency liquid chromatograph was composed of a double pump, and the pump A was attached to the organic phase acetonitrile, and the pump B was attached to the 0.1% aqueous solution of formic acid. The flow rate of pump A and pump B is controlled by chromatographic working stations, with a total flow rate of 1.0 mL / min, and finally mixed into a acetonitrile mass fraction of 34.50%, 44.13%, 64.83%, 87.67%, 100.00% acetonitrile-aqueous solution, and balanced respectively The column was 20 min, and the column temperature was controlled at 30 ° C; the tolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com