Construction method for large-span cast-in-situ beam slab support system of plant

A support system and cast-in-place beam-slab technology, which is applied to the on-site preparation of formwork/formwork/work frame, pillars, and building components, etc., can solve the problem of large built-in equipment, unsatisfactory, and inability to carry out stress and deformation of the support system. problems such as measurement and control, to achieve the effect of cost saving and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

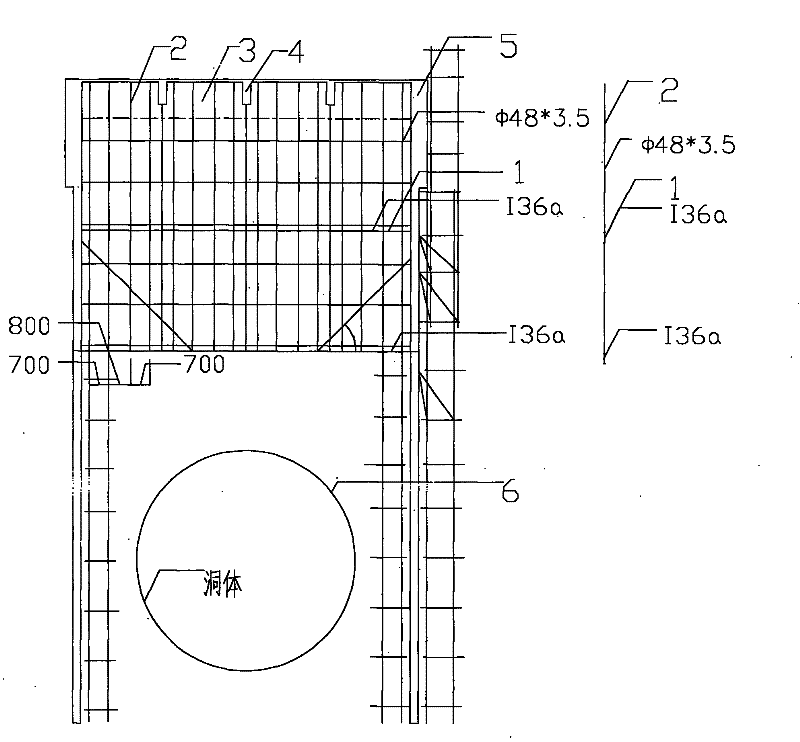

[0011] figure 1 It is a schematic diagram of erecting Mantang scaffolding according to the specific embodiment of the present invention. Among them, 1 is pre-embedded I36a I-beam, 2 is full scaffolding ф48*3.5 steel pipe, 3 is the main girder of the cast-in-place roof with a cross-sectional size of 1400*350, and 4 is the secondary beam of the cast-in-place roof with a cross-sectional size of 900*300 , 5 is the cast-in-place shear wall, 6 is the built-in equipment, with a diameter of 7.860m, a length of 26.040m, and a central elevation of 5.800m.

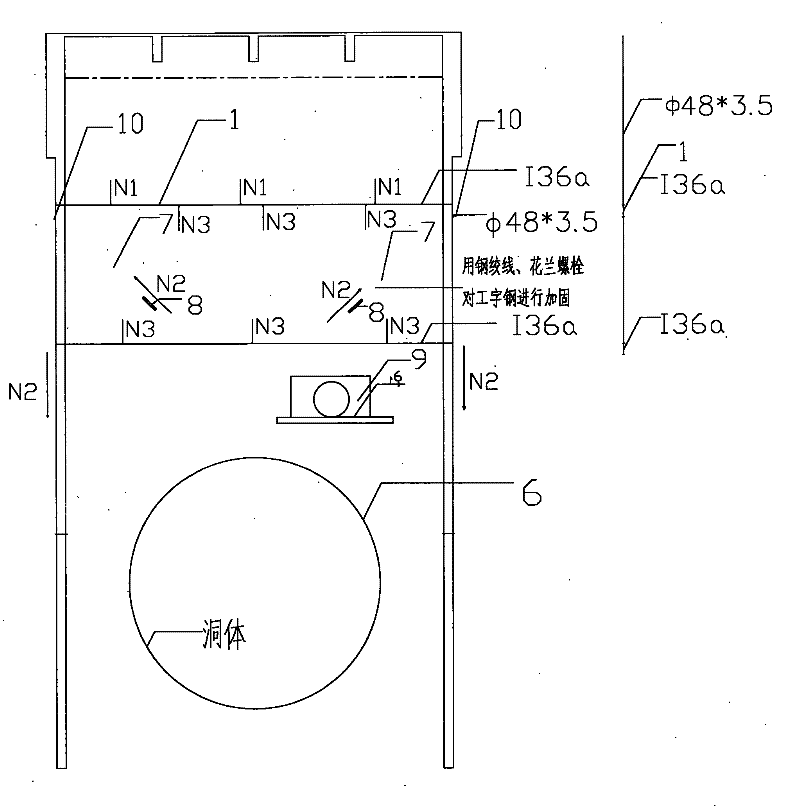

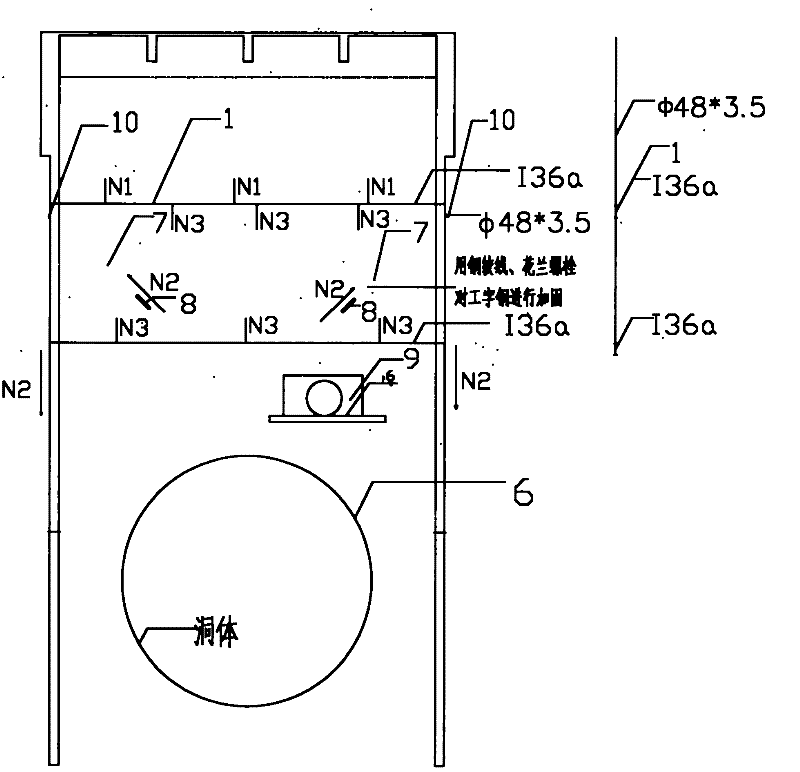

[0012] figure 2 It is a schematic diagram of the unloading and measurable and controllable process implementation of the I-beam in the specific embodiment of the present invention. Among them, 1 is pre-embedded I36a I-beam, 6 is built-in equipment, diameter 7.860m, length 26.040m, center elevation 5.80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com