Modeling method of temperature and pressure reducing device

A technology of temperature reduction and decompression and modeling method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as the difficulty of applying momentum equation integration, steam state fluctuations, and time-consuming simulation calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

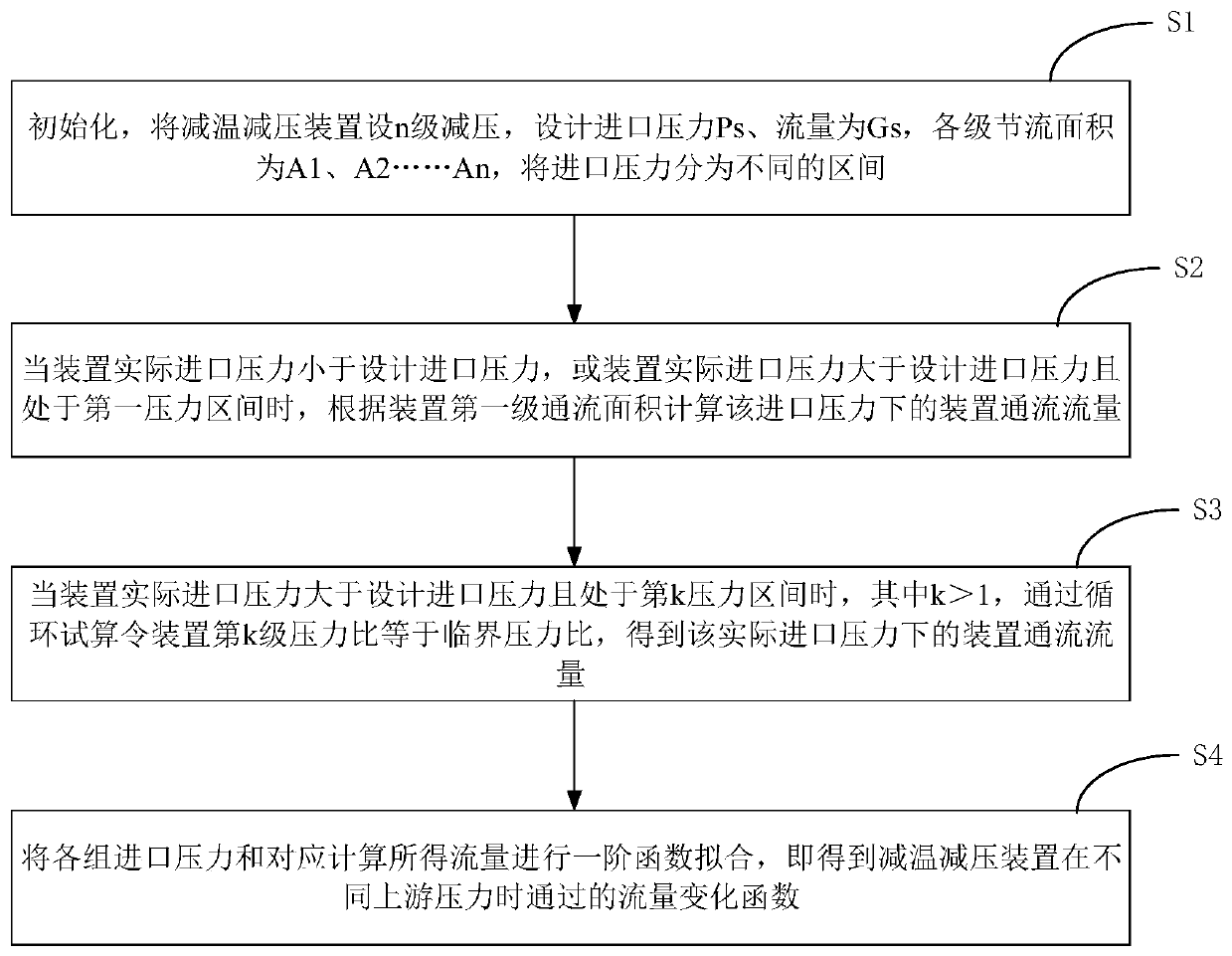

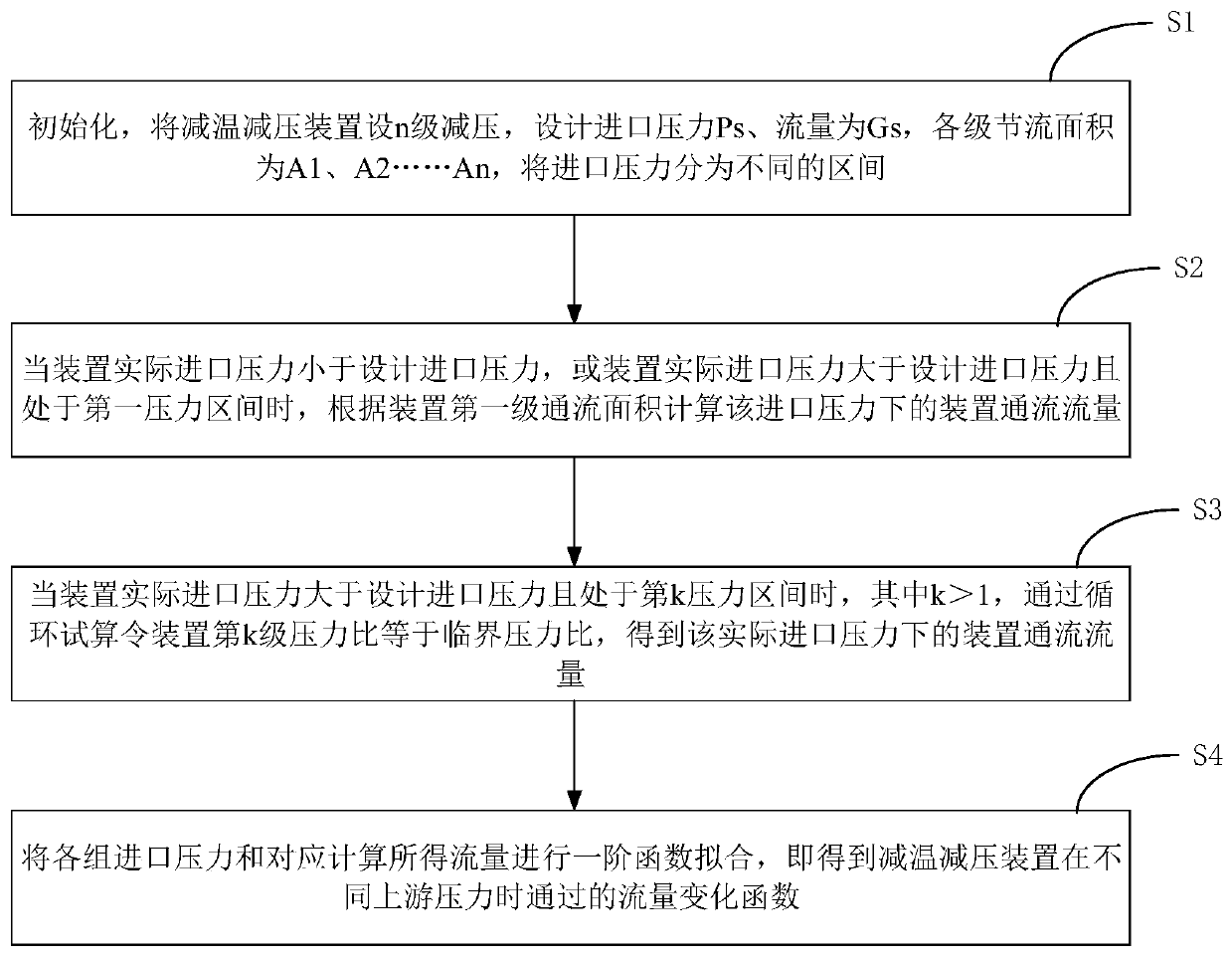

[0014] Such as figure 1 As shown, the modeling method of the temperature and pressure reduction device of the present invention includes:

[0015] S1, initialization

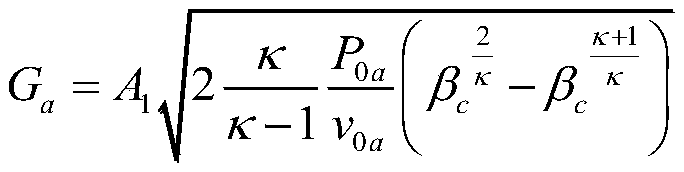

[0016] S1.1. The temperature and pressure reduction devices are set up with n stages of pressure reduction, and the design inlet pressure is P s , design flow G s , the throttling area of each stage is A 1 、A 2 ...A n ;

[0017] S1.2. Divide the inlet pressure into different intervals, respectively χ 1 =(0MPa,3.9MPa], χ 2 =(3.9MPa,5MPa], χ 3 =(5MPa,6.1MPa], χ 4 =(6.1MPa,7.2MPa],......χ k =(P k-min ,p k-max ], the division of the pressure range is based on the following: the decompression process at all levels should be an isenthalpic process, and the value of the inlet pressure of the device P k-max It should be possible to make the saturated steam entha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com