Porous concrete aggregate design method based on working performance

A technology of porous concrete and work performance, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problems of lack of reliable calculation to ensure porosity and pore size distribution, difficult to guarantee the work performance of porous concrete, etc., to reduce the number of tests. Quantity, the effect of improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The design method of porous concrete aggregate based on work performance includes the following steps:

[0036] 1. The target working performance of the designed porous concrete is: density 1950kg / m 3 , porosity 22%, U-shaped slump angle 25°. Determine the volume of each component according to the relationship between the volume of pores, slurry and aggregate and the working performance,

[0037] V=0.2, P=0.275, A=0.525.

[0038] 2. Adjust the volume of each component.

[0039] V'+P'=V+P-5%=0.425

[0040] A'=A+5%=0.575

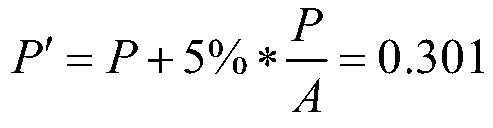

[0041]

[0042] V'=V+P-5%-P'=0.124

[0043] 3. Target porosity e for aggregate design A =V'+P'=0.425

[0044] According to the relationship between the porosity of the aggregate and the percentage of aggregates with four particle sizes:

[0045] e A =40.1A+42.6B+43.8C+37.5S-4.9AB-13.7AC-7.1BC-42.2AS-38BS-27.2CS A, B, C, and S are respectively the percentage of aggregates with three particle sizes in the total aggregate volume percentage.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com