Tensioner shaft pin bending device and bending method

A technology of bending device and tensioner, which is applied in the field of tensioner production, can solve the problems of high labor cost, low efficiency, and high labor intensity, and achieve the effects of low labor cost, high degree of automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

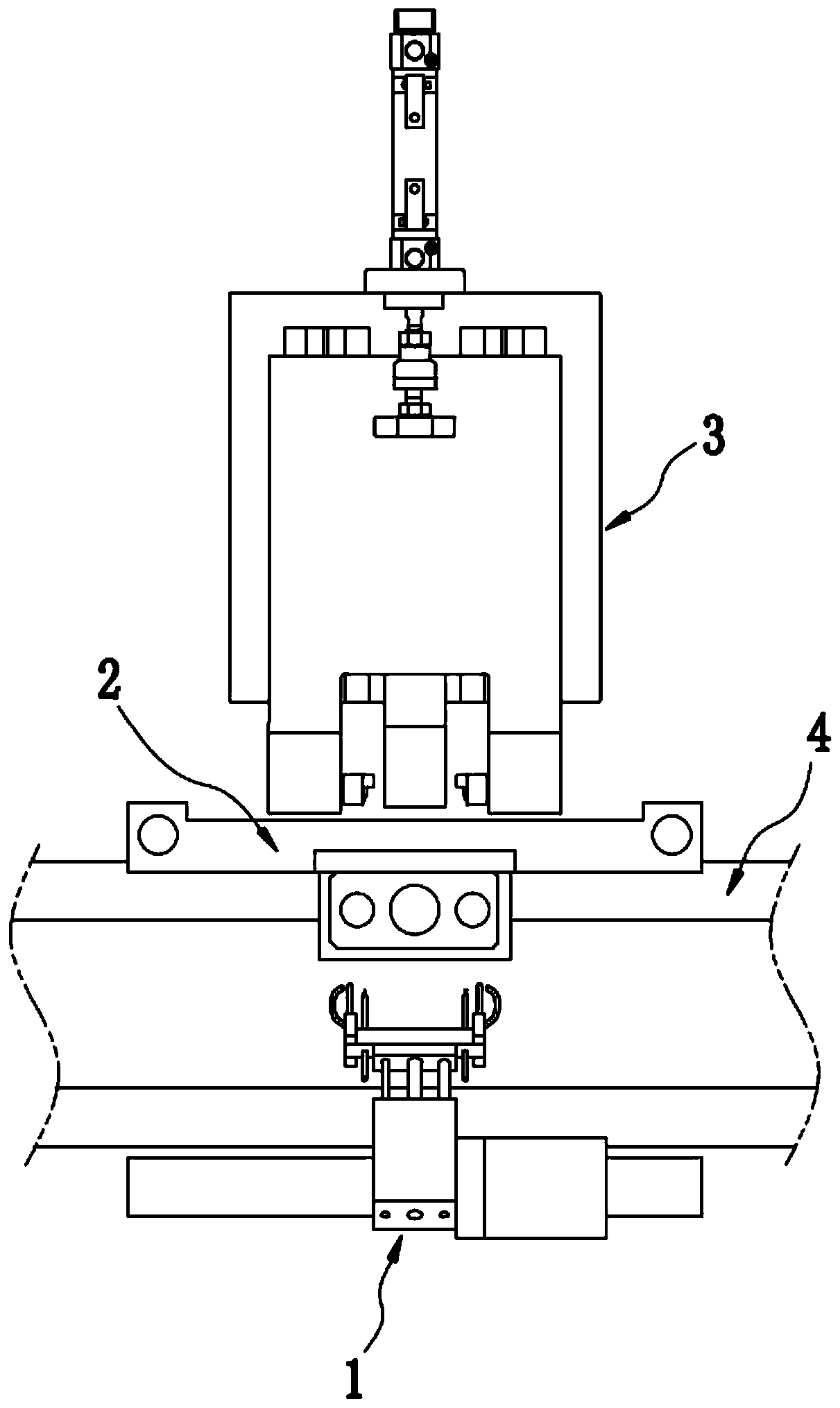

[0070] A tensioner shaft pin bending device, such as figure 1 , 8 As shown, it includes an adjusting device 1 , a clamping device 2 and a bent pin device 3 which are arranged in cooperation with each other. Such as figure 1 As shown, the conveying line 4 extends horizontally, and the adjustment device 1, the clamping device 2 and the bending pin device 3 are arranged longitudinally on the shaft pin bending station on the conveying line 4, and the adjusting device 1 is arranged on the conveying One side of the line 4 , the bending pin device 3 is arranged on the other side of the conveying line 4 , and the clamping device 2 is arranged above the conveying line 4 .

[0071] The state before the shaft pin 5 on the tensioner described in this embodiment is bent is as follows: Figure 10 As shown in , it has a bent end 51 and a straight end 52, when assembling the shaft pin 5 as Figure 9 As shown in , insert its straight end 52 down vertically into the pin holes at both ends o...

Embodiment 2

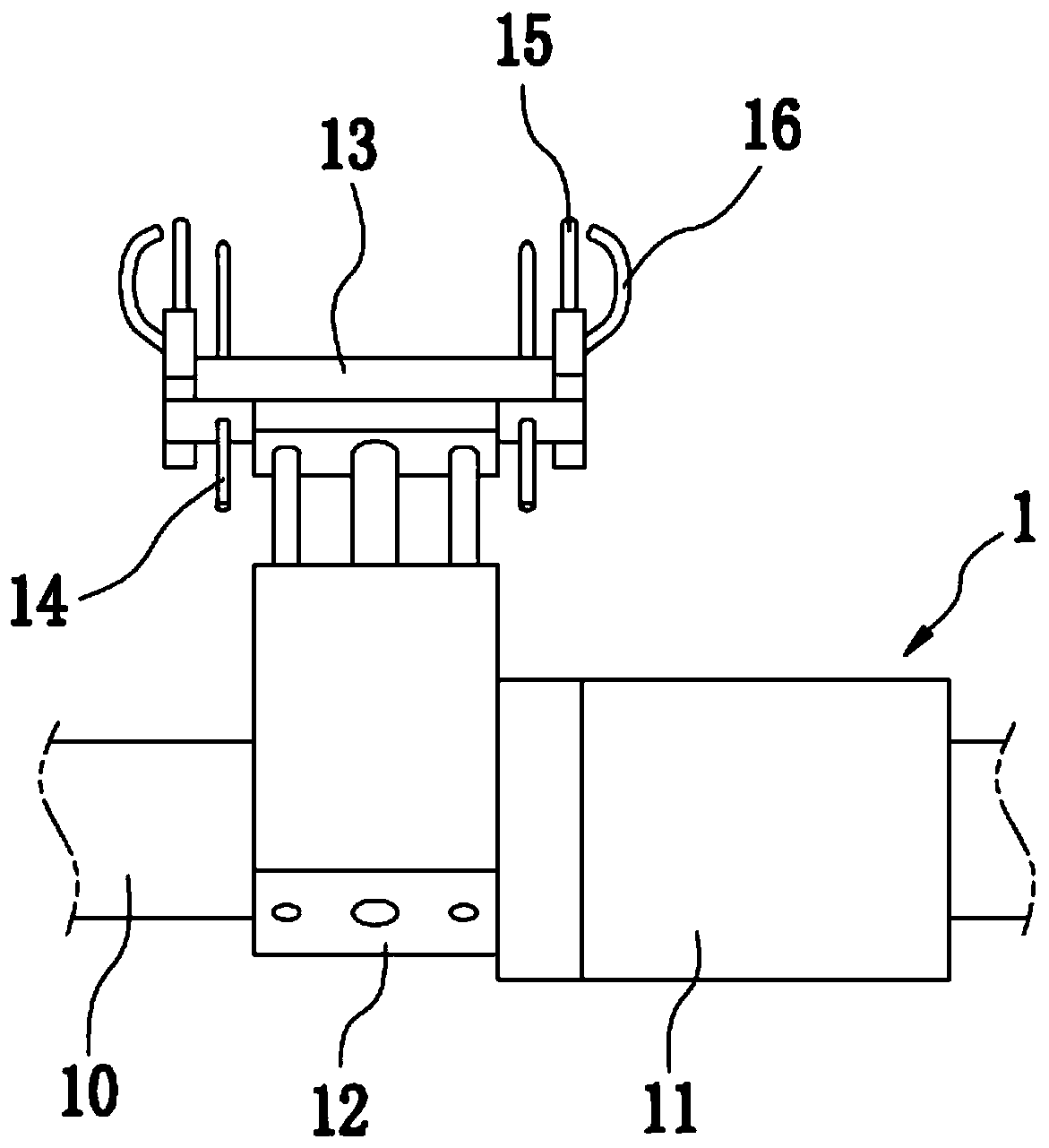

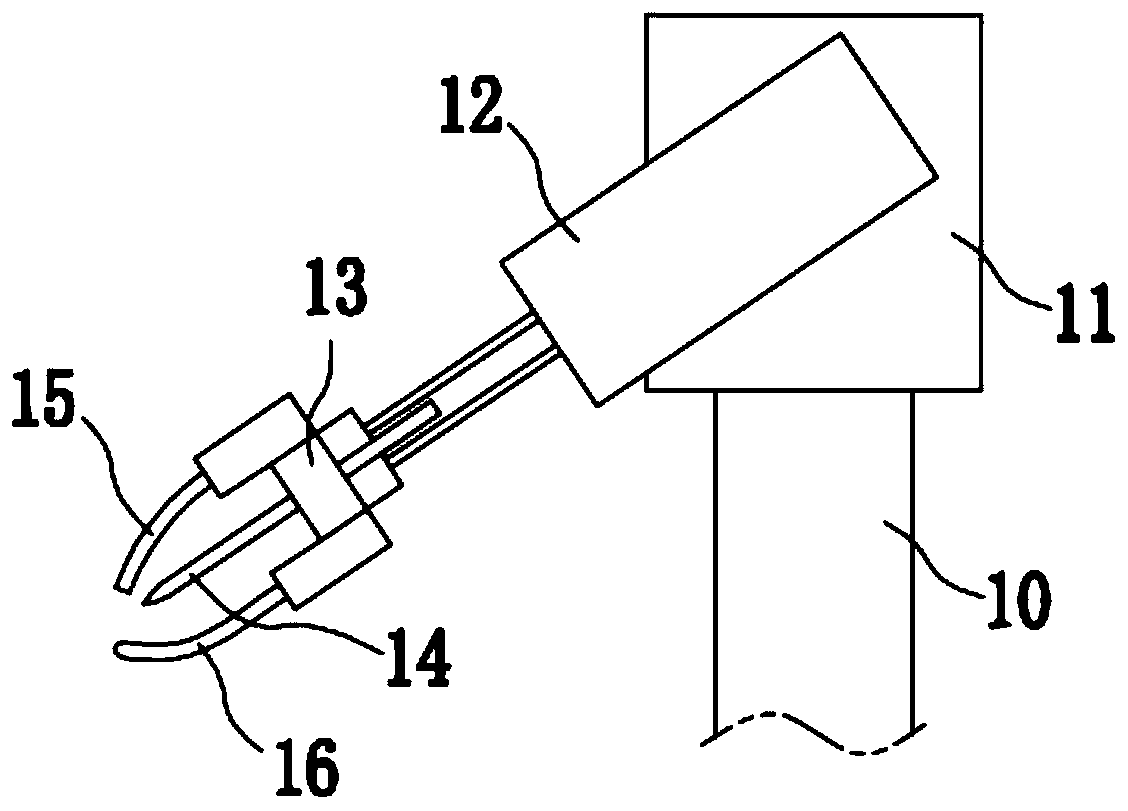

[0075] The pin bending device of the tensioner in this embodiment, on the basis of the first embodiment, provides a specific structure of the adjusting device 1 . Such as figure 2 , 3 As shown, the adjustment device 1 includes a cylinder one 12, a needle seat 13, an upper air pipe 15 and a lower air pipe 16; a vertical plate 10 is vertically fixed on one side of the conveying line 4, and a mounting seat one 11 is fixed on the upper end of the vertical plate 10 ;Such as figure 2 As shown in , the cylinder one 12 is obliquely fixed on the left side of the mounting base one 11; the needle seat 13 is fixed on the end of the piston rod of the cylinder one 12; the upper air pipe 15 and the lower The trachea 16 is respectively fixed on the upper and lower sides of the needle holder 13; the upper trachea 15 and the lower trachea 16 can blow out the airflow, and the flow of the airflow can be controlled. Specifically, the upper trachea 15 and the lower trachea 16 adopt The metal c...

Embodiment 3

[0082] The pin bending device of the tensioner in this embodiment, on the basis of Embodiments 1 and 2, provides a specific structure of the clamping device 2 . Such as Figure 4 , 5 As shown, the clamping device 2 includes a cylinder two 22 and a mechanical claw 23; a support 20 is vertically fixed on one side of the conveying line 4, and the support 20 includes two vertically arranged columns and a horizontally arranged upper end of the column. The crossbeam 200, the front side of the crossbeam 200 extends to the top of the conveying line 4, the middle part of the upper side of the crossbeam 200 is fixed with the mounting seat 21, and the piston rod of the cylinder 222 is vertically fixed on the mounting seat 2 downwards. The front side of 21; said mechanical claw 23 claws are vertically fixed on the piston rod end of said cylinder two 22 downward; said mechanical claw 23 is a pneumatic mechanical claw.

[0083] After the shaft pin 5 rotates in place, control the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com