3D printing device and method of multi-scale fiber-reinforced micro-channel active tubular tissue

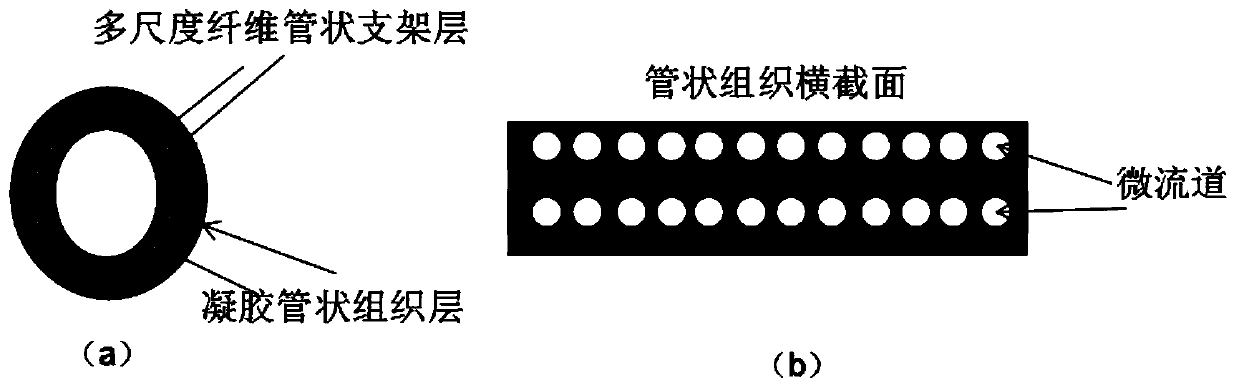

A fiber-reinforced, printing device technology, applied in tissue cell/virus culture devices, biomaterial sampling methods, biochemical equipment and methods, etc., can solve the problem that hydrogel tubular tissues cannot meet the mechanical properties of tubular tissues. , The problem of nutrient supply and delivery of three-dimensional tubular tissue has not been well solved, so as to achieve the effect of promoting survival and growth and ensuring supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

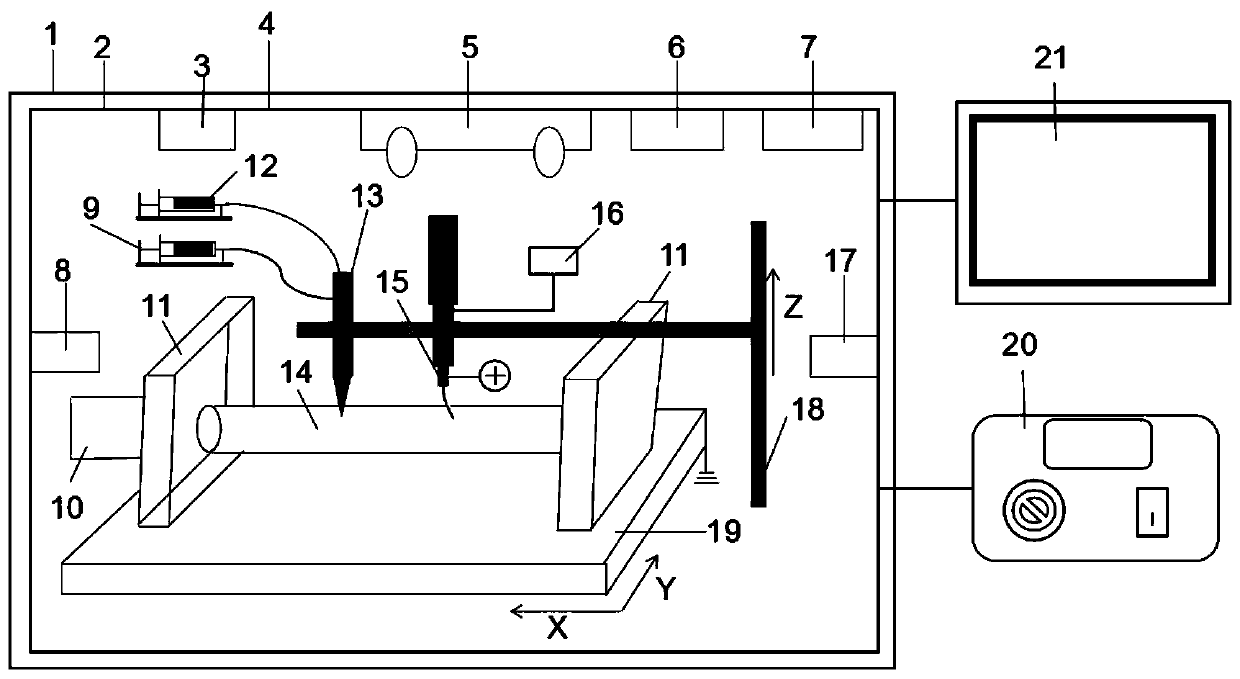

[0027] refer to figure 1 , a multi-scale fiber-reinforced microfluidic channel active tubular tissue 3D printing device, including an ultra-clean test bench 1, a printing device shell 2 is placed inside the ultra-clean test bench 1, and a printing platform 19 is arranged in the printing device shell 2, and a printing platform 19 Grounded, the printing platform 19 can move along the X-Y two directions, the receiving cylinder 14 is connected with the bearing seat 11 on the printing platform 19, the receiving cylinder 14 is installed on the bearing seat 11, and it is easy to disassemble; the receiving cylinder 14 moves with the printing platform 19 , can realize horizontal movement in XY two directions; the end of the receiving drum 14 is connected to the output shaft of the motor 10, and the receiving drum 14 can rotate at a certain speed under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com