A kind of thermosensitive antibacterial tussah silk fiber and preparation method thereof

A technology of tussah silk and fiber is applied in the field of temperature-sensitive antibacterial tussah silk fiber and its preparation, and can solve the problems of single function, poor washing fastness, low grafting rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

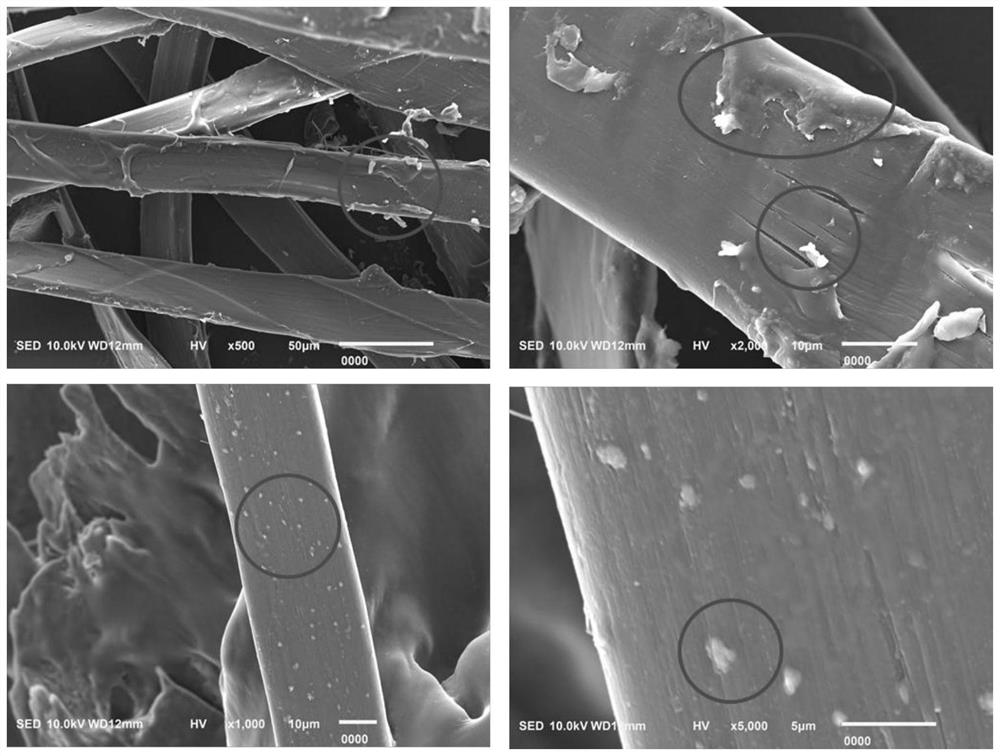

[0028] The invention provides a kind of preparation method of thermosensitive antibacterial tussah silk fiber, comprises the following steps:

[0029] (1) swelling tussah silk fibers in an ionic liquid solution to obtain swelling fibers;

[0030] (2) Mixing the swollen fiber and the dithiothreitol solution for a reduction reaction to obtain a reduced fiber; the reduced fiber has an active mercapto group;

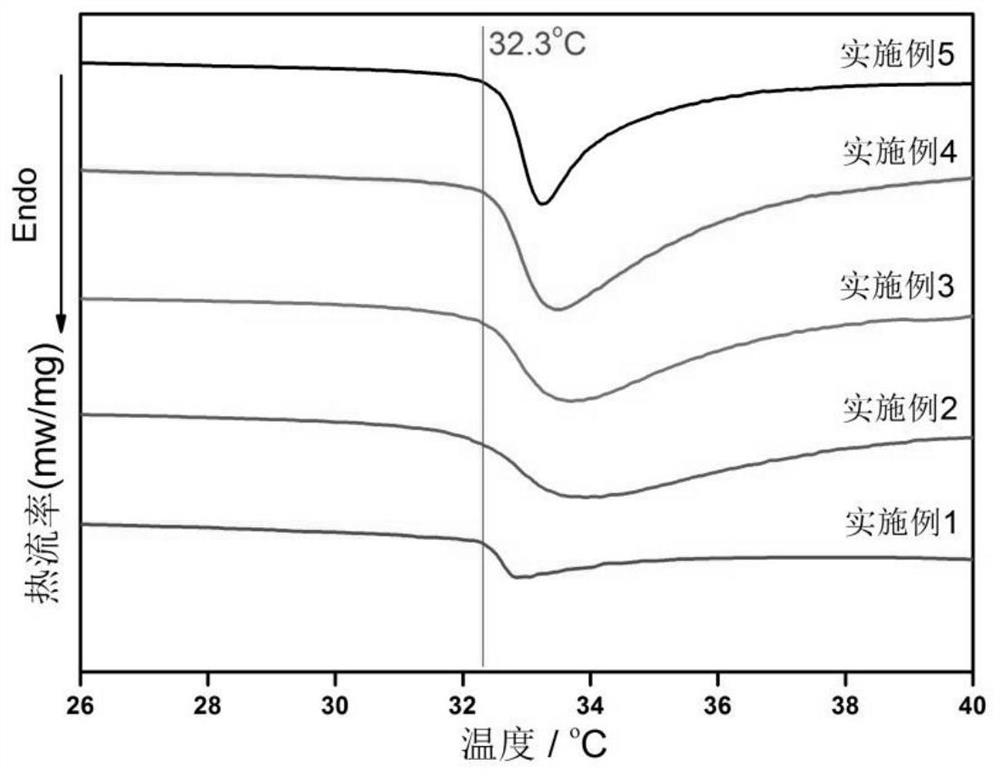

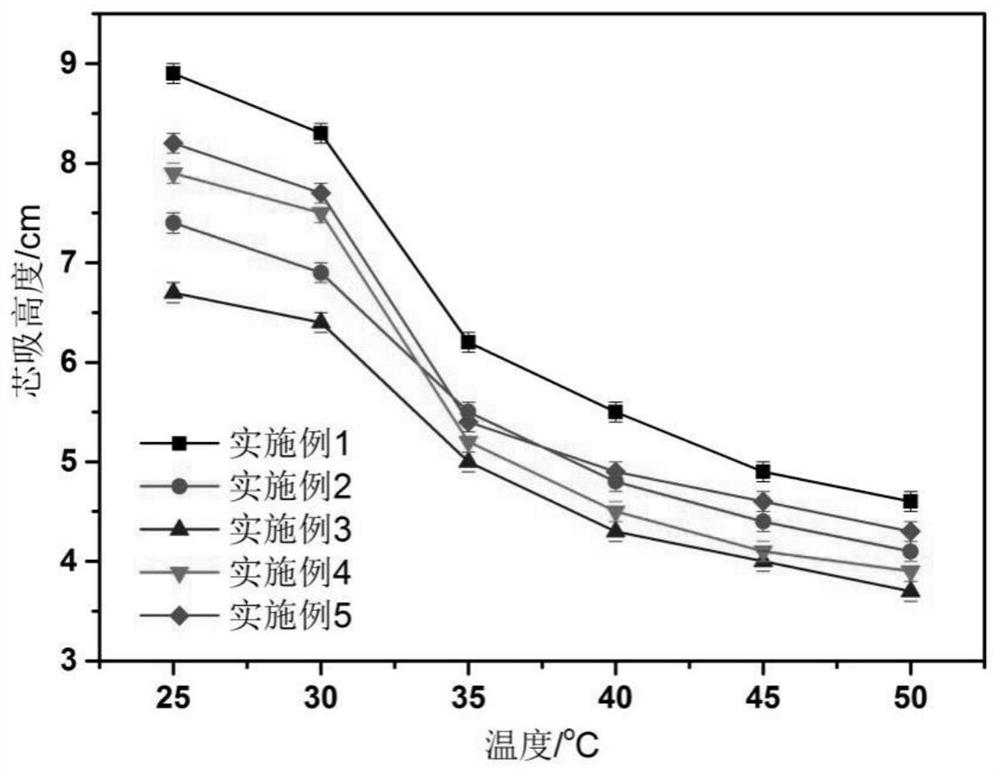

[0031] (3) Under the action of the initiating system, the reduced fiber and N-isopropylacrylamide are grafted in a PBS solution, the antibacterial peptide solution is added during the reaction, and then cross-linked and encapsulated using transglutaminase , to obtain temperature-sensitive antibacterial tussah silk fiber; the initiation system is horseradish peroxidase-hydrogen peroxide-ascorbic acid system.

[0032] The invention swells the tussah silk fiber in the ion liquid solution to obtain the swollen fiber. The present invention has no special requirements on the fin...

Embodiment 1

[0060] (1) Swell tussah silk fibers with 5% 1-ethyl-3-methylimidazole acetate solution at 50°C for 3 hours to obtain swollen fibers, wash with distilled water, remove surface reagents, and set aside .

[0061] (2) Immerse the swollen fiber in 10 mmol / L dithiothreitol solution, adjust the pH to 6.5-7.5 with sodium carbonate solution, and treat it with magnetic stirring at 30°C for 4 hours. After the reaction, take out the obtained reduced fiber and wash it with distilled water ,stand-by.

[0062] (3) Dissolve 0.565g of N-isopropylacrylamide in 30ml of PBS solution (0.1mol / L, pH=7.0). After all the solids are dissolved, add 0.302g of reduced fiber, blow in nitrogen, and soak tussah silkworms at room temperature Silk fiber for 1 hour, then add 0.531g of 30% hydrogen peroxide solution, then add 0.531g of ascorbic acid, add 0.033g of horseradish peroxidase after 30 minutes of stabilization, heat in a water bath at 40°C for 2 hours, then add 2% concentration of bovine antimicrobial...

Embodiment 2

[0064] (1) Use 1-ethyl-3-methylimidazole acetate solution with a mass concentration of 10% to swell tussah silk fibers at 50°C for 3 hours to obtain swollen fibers, wash with distilled water, remove surface reagents, and set aside .

[0065] (2) Immerse the swollen fibers in 15 mmol / L dithiothreitol solution, adjust the pH to 6.5-7.5 with sodium carbonate solution, and magnetically stir at 30°C for 3 hours. After the reaction, take out the obtained reduced fibers and wash them with distilled water ,stand-by.

[0066] (3) Dissolve 0.678g of N-isopropylacrylamide in 30ml of PBS solution (0.1mol / L, pH=7.0). After all the solids are dissolved, add 0.418g of reduced fiber, blow in nitrogen, and soak tussah silkworms at room temperature Silk fiber for 1 hour, then add 0.637g of 30% hydrogen peroxide solution, then add 0.637g of ascorbic acid, add 0.0369g of horseradish peroxidase after 30 minutes of stabilization, heat in a water bath at 40°C for 2 hours, then add 2% concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com