Construction method of metal framework system arranged on curtain wall built by ganged bricks

A metal skeleton and construction method technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of not fully meeting the requirements of stability and forming effect, and achieve the effect of improving stability and forming effect, and increasing structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

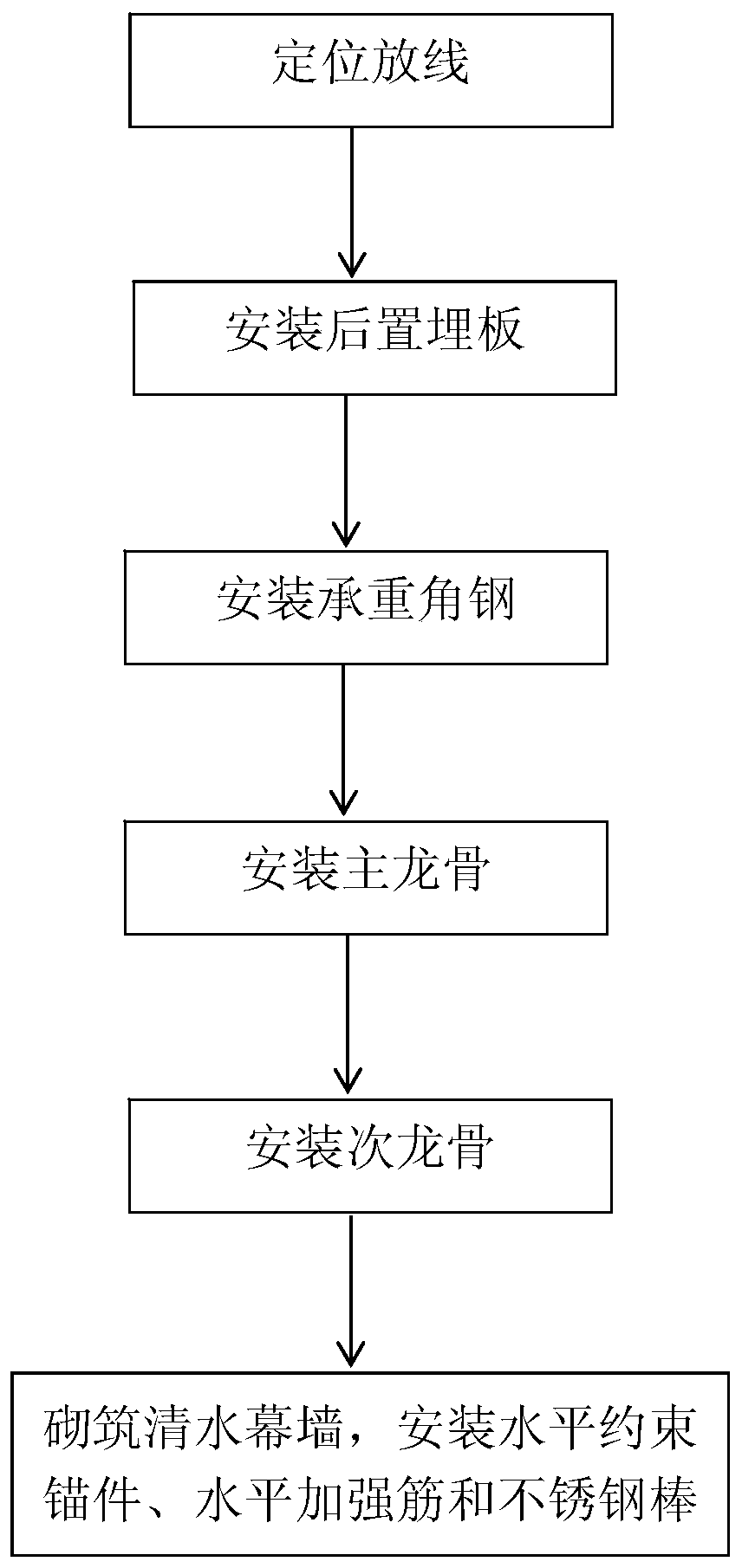

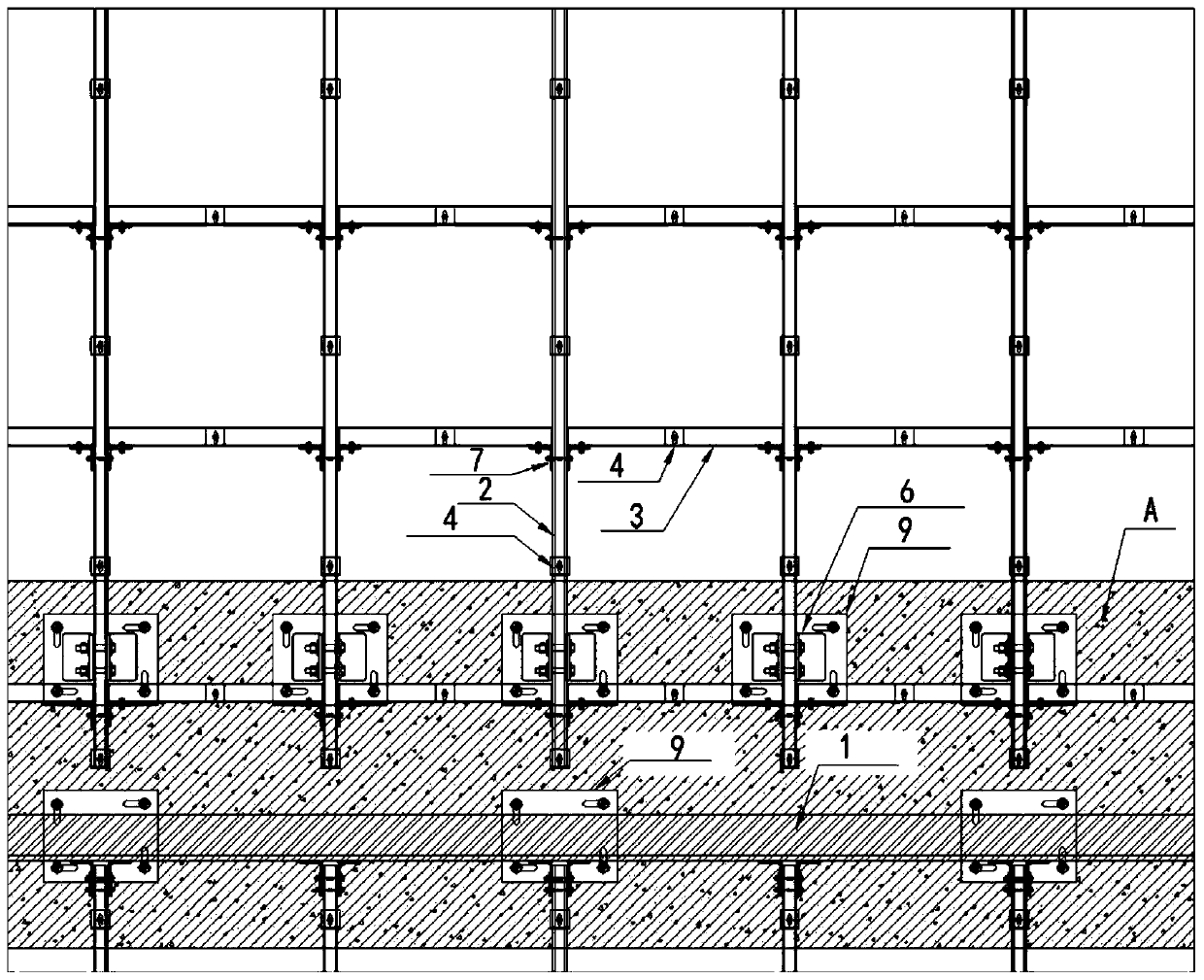

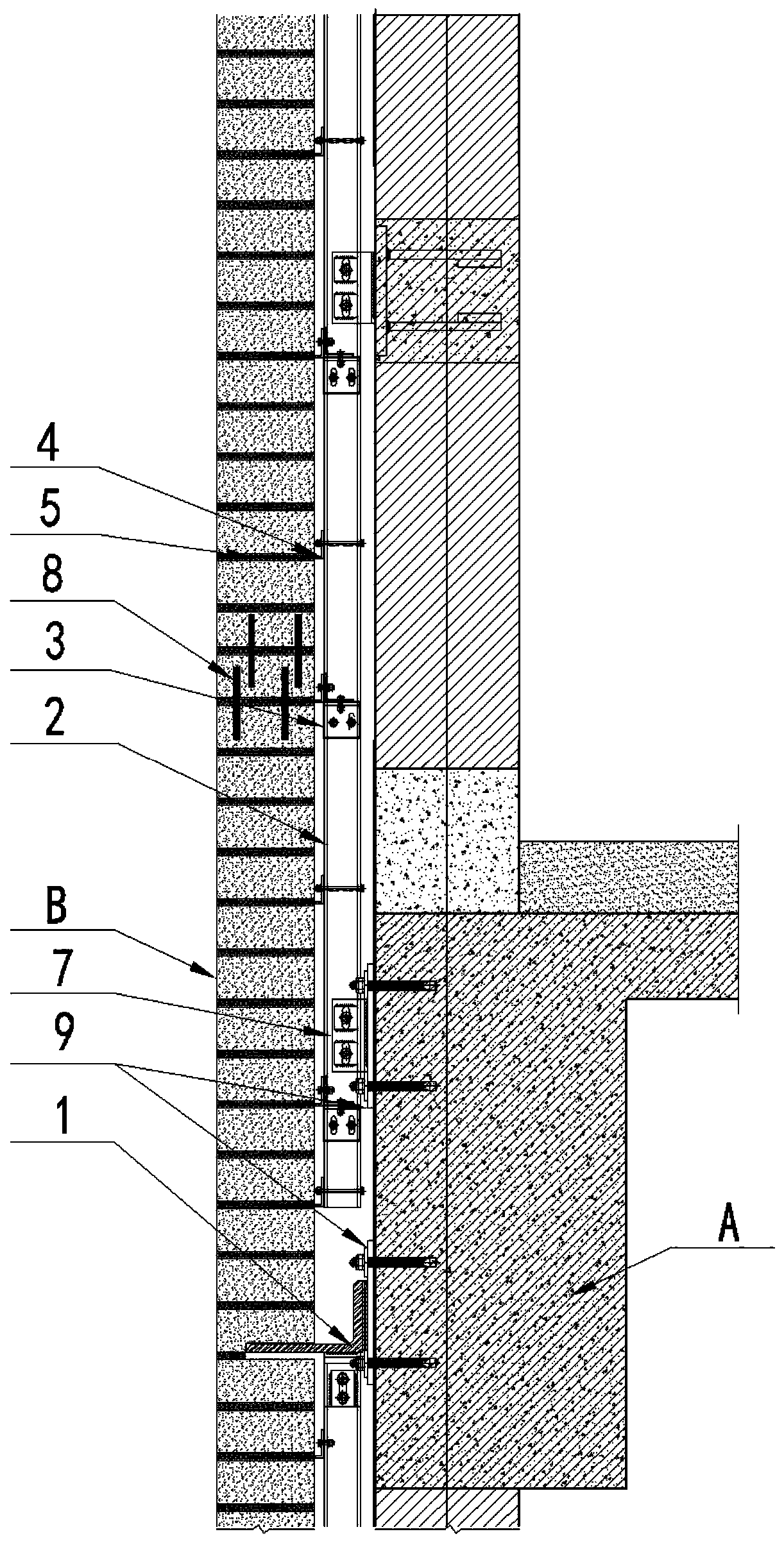

[0048] A construction method in which a metal skeleton system is arranged on a clear-faced brick curtain wall. The metal skeleton system consists of a load-bearing angle steel 1, a main keel 2, a secondary keel 3, a horizontal constraint anchor 4, a horizontal reinforcing rib 5, and a hot-dip galvanized adapter 6. It is composed of hot-dip galvanized steel corner code 7, stainless steel rod 8 and rear embedded plate 9. The construction method of the metal skeleton system set on the clear water brick curtain wall, such as figure 1 As shown, including: 1) Positioning and setting out; 2) Installing the rear embedded plate 9; 3) Installing the load-bearing angle steel 1; 4) Installing the main keel 2; 5) Installing the secondary keel 3; Install the horizontal restraint anchor 4, the horizontal rib 5 and the stainless steel rod 8, a total of 6 procedures, such as figure 2 and image 3 As shown, its specific operation is as follows:

[0049] 1) Positioning and setting out

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com