Oil exploitation method based on nano motor and application of nano motor

A technology of oil extraction and motor, which is applied in the field of nano motor application, can solve the problem of difficult oil extraction, and achieve the effect of improving recovery rate and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

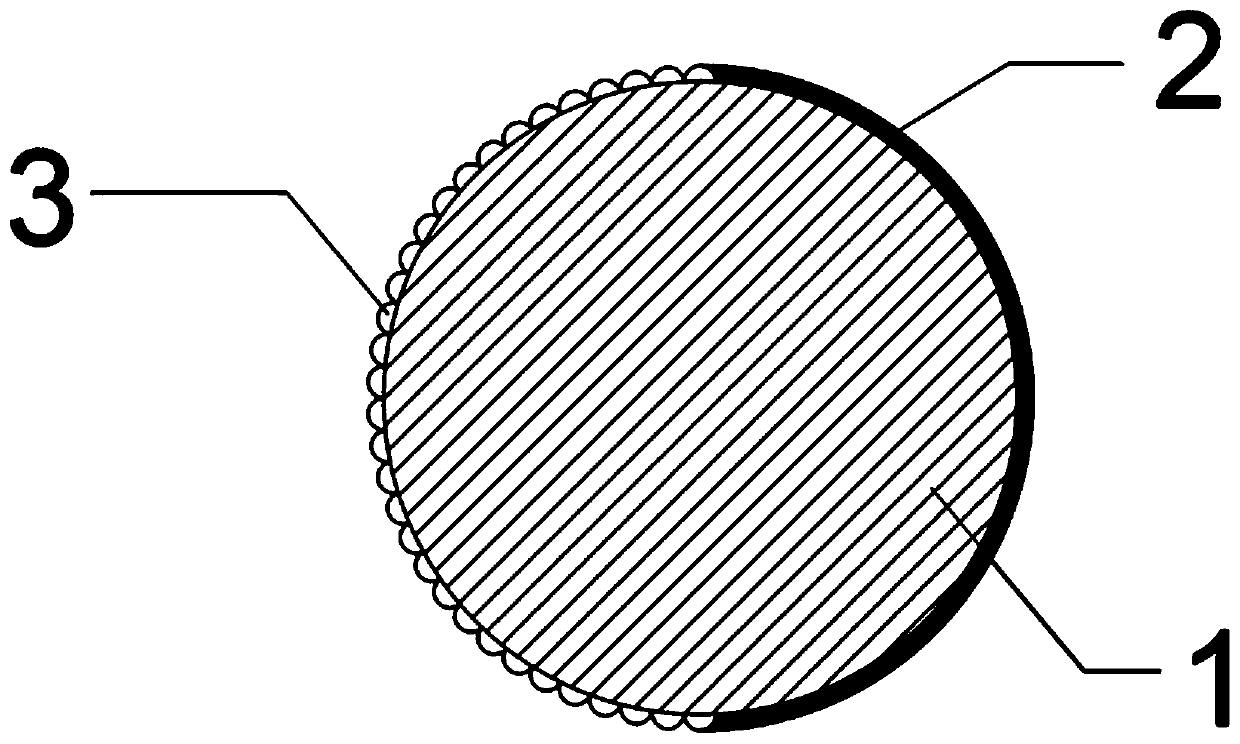

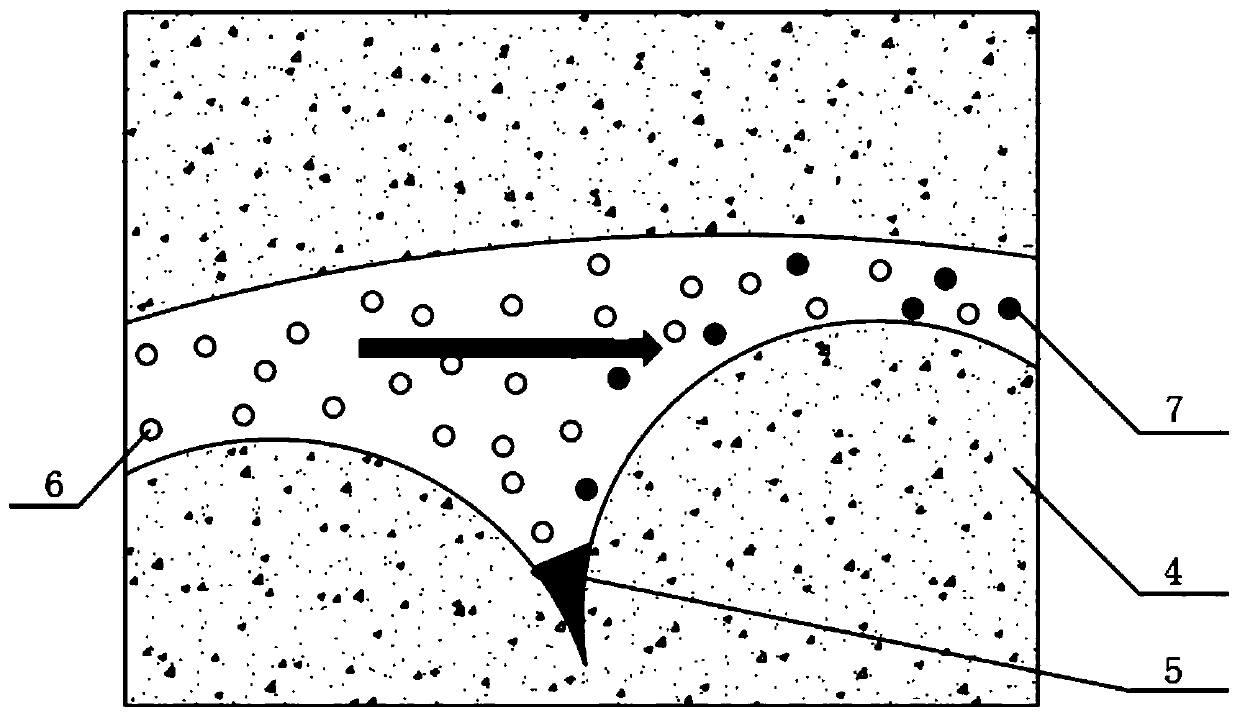

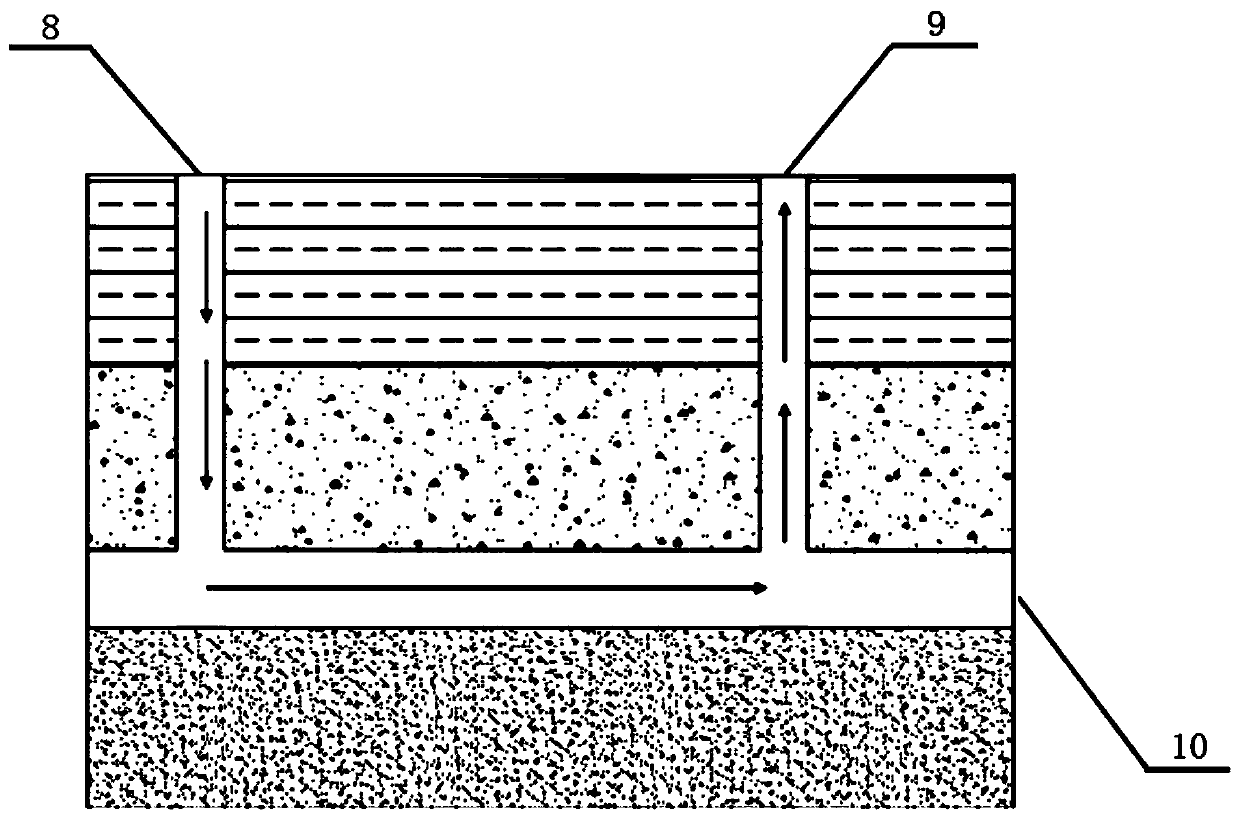

[0026] Such as figure 1 Shown, a kind of oil extraction method based on nanomotor, described oil extraction method based on nanomotor comprises:

[0027] Step 1: Take a nanomotor made of a sphere 1 with half a spherical surface vapor-deposited with a catalytic metal layer 2 and the other half spherical surface modified with a hydrophobic and lipophilic group 3, mix the nanomotor with deionized water to obtain a nanomotor motor suspension;

[0028] Step 2: Mix the hydrogen peroxide solution with the nanomotor suspension and inject it into the formation of the oil well;

[0029] Step 3: The catalytic metal layer 2 evaporated on the surface of the nanomotor catalyzes the decomposition of hydrogen peroxide, and generates an oxygen concentration gradient to make the nanomotor move;

[0030] Step 4: When the nanomotor moves in the formation, the hydrophobic and lipophilic group 3 modified on the surface of the nanomotor combines with the oil droplet, and the nanomotor with the oil...

specific Embodiment approach 2

[0033] The hydrogen peroxide solution is a hydrogen peroxide solution with a volume fraction of 5%-30%.

specific Embodiment approach 3

[0035] Such as figure 1 As shown, the diameter of the sphere 1 is 500nm-40μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com