Multi-objective structure optimization method of magnetic gear brushless direct current motor

A technology of brushing DC motor and optimization method, applied in the field of electric drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

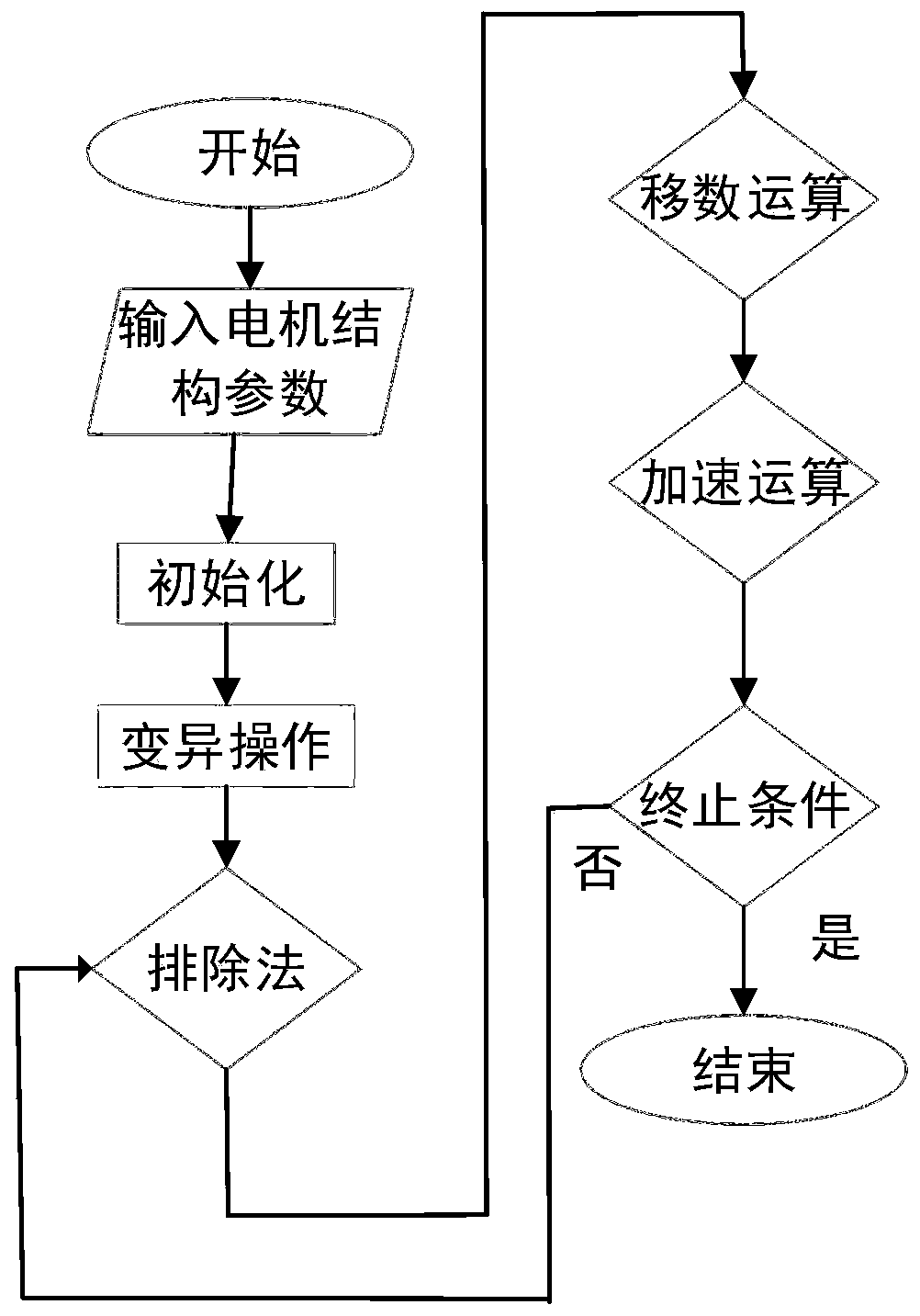

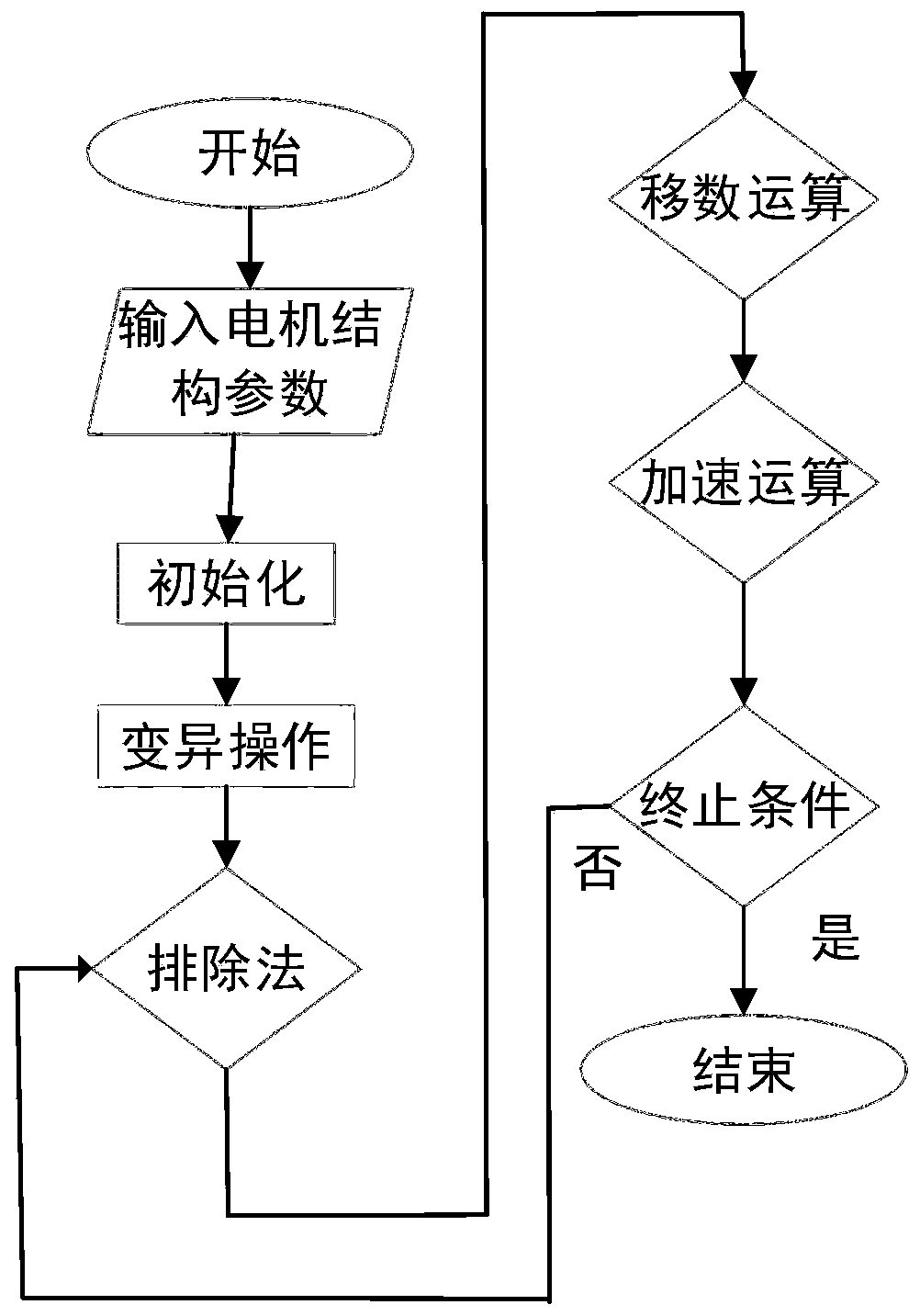

[0048] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0049] Embodiment 1 provides a multi-objective structure optimization method for a magnetic gear brushless DC motor, comprising the following steps:

[0050] The steps of the chaotic search reverse learning difference method can be briefly described as follows:

[0051] Step S1, initialization

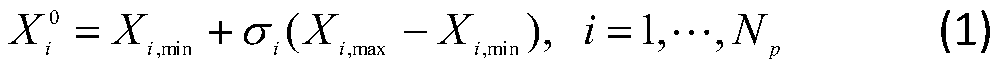

[0052]Select the number of stator slots, the number of rotor slots, the outer diameter of the rotor end ring, and the inner diameter of the rotor end ring among the structural parameters of the magnetic gear brushless DC motor as the structural parameters, and generate the first four groups at the same time; choose any structural parameter as one of the groups, Initially, the group generation method is to start randomly in the search space, and its progress is as follows:

[0053]

[0054] In formula (1), is the initial group, σ i ∈(0,1] random numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com