Composite electrolyte, protective film, protected negative electrode, lithium metal battery and method for manufacturing protected negative electrode

A technology of composite electrolyte and protective film, which is applied in the field of composite electrolyte and can solve the problems of poor charging and discharging characteristics of lithium secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example Embodiment approach

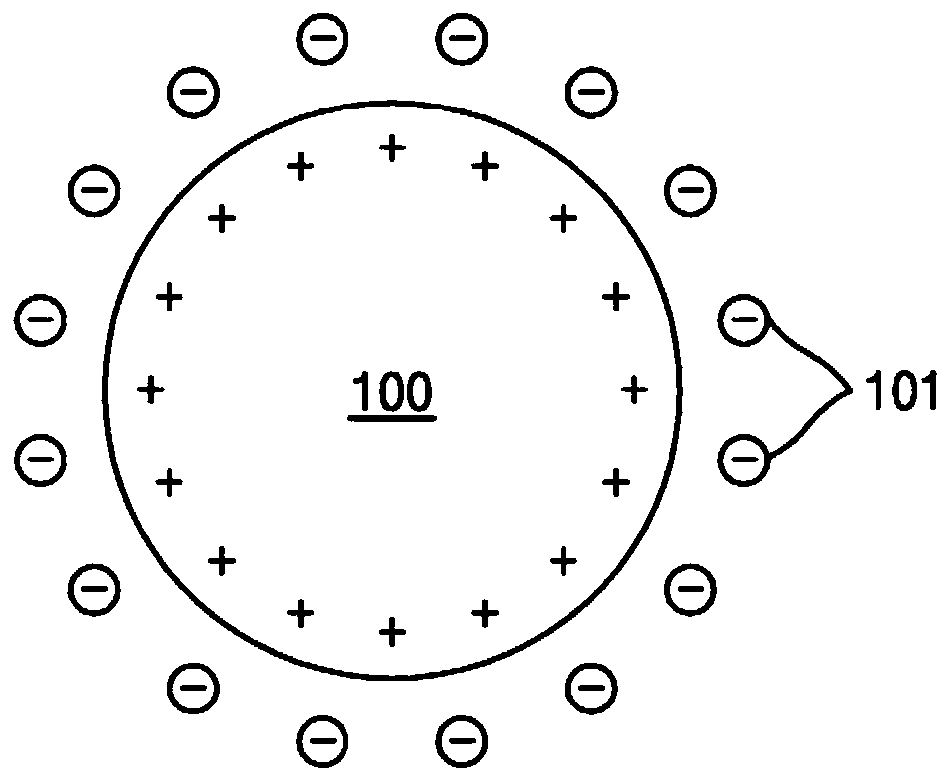

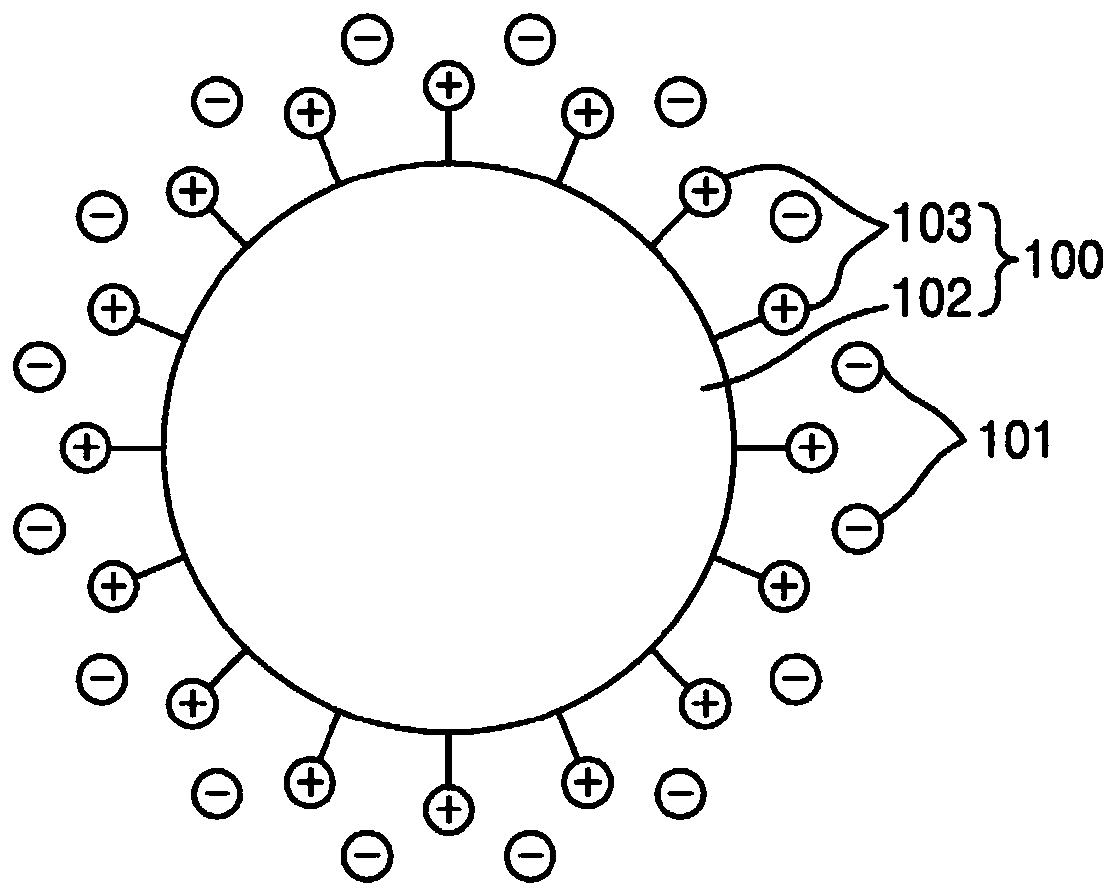

[0041] According to an example embodiment, a composite electrolyte includes: positively charged particles, positively charged particles by having a coordination bond with a cation, or a combination thereof; and a lithium salt. Since the composite electrolyte includes positively charged particles and / or particles positively charged by having coordination bonds with cations (i.e., anion-accepting particles or anion-absorbing particles), the anions in the composite electrolyte can be localized to the surface and / or near the particle. While not wishing to be bound by theory, it is understood that localizing the anions to the surface of the particles inhibits the migration of anions in the composite electrolyte. It is understood that suppressed anion migration leads to increased lithium ion migration in the composite electrolyte, thereby leading to an increase in the lithium ion migration number in the composite electrolyte.

[0042] refer to figure 1 , in order to maintain charg...

Embodiment 1

[0246] Embodiment 1: PEO+MS-DEAE+ lithium salt

[0247] Polyethylene oxide (PEO) was mixed with acetonitrile to obtain a solution of 5 weight percent (wt%) PEO in acetonitrile. A mixture containing particles and lithium bis(fluorosulfonyl)imide (LiFSI, LiN(SO 2 F) 2 ) to prepare a composite electrolyte-forming composition.

[0248] Anhydrous THF was added to MS-DEAE microspheres (having about 3 μm average diameter), thus obtaining the mixture comprising particles. Here, the amount of the particles is about 5% by weight.

[0249] A composite electrolyte-forming composition was prepared in which the particles were in an amount of 15 parts by weight based on 100 parts by weight of PEO, and the amount of LiFSI was 30 parts by weight based on 100 parts by weight of PEO.

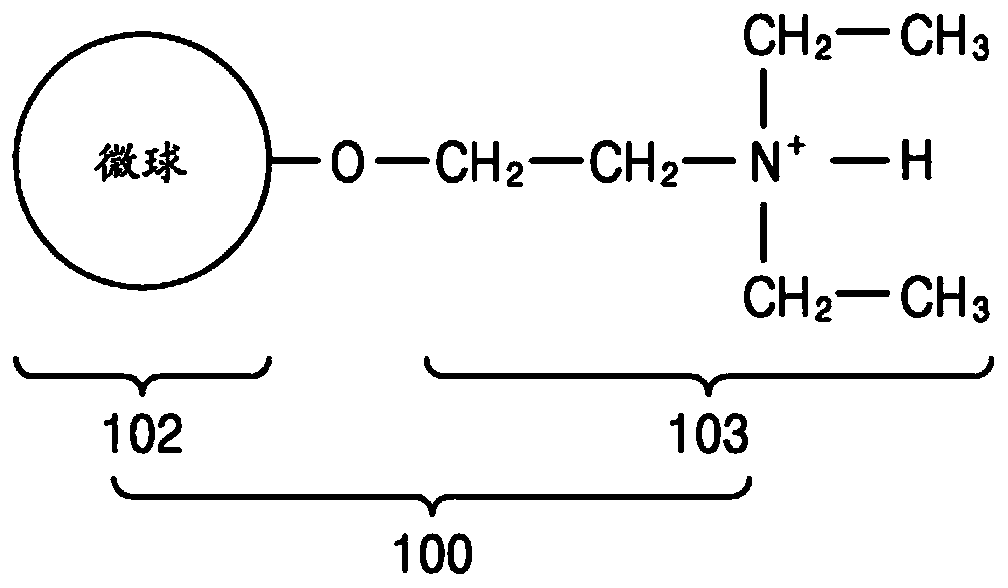

[0250] Formula 8

[0251]

[0252] The prepared composite electrolyte-forming composition was cast on the part, and the acetonitrile and THF in the resultant were gradually evaporated in an argon glove bo...

Embodiment 2

[0261] Example 2: MS-DEAE+lithium salt protective film / protected negative electrode

[0262] Anhydrous THF was added to MS-DEAE microspheres (with a diameter of about 3 μm) in which poly(styrene-divinylbenzene) copolymer particles were covalently attached to oxyethylenediethylammonium groups represented by average diameter) to obtain a mixture containing particles. Here, the amount of the particles is about 5% by weight.

[0263] Formula 8

[0264]

[0265] To the prepared particle-containing mixture was added lithium bis(fluorosulfonyl)imide (LiFSI, LiN(SO 2 F) 2 ) to prepare a protective film-forming composition. The amount of LiFSI is about 30 parts by weight based on 100 parts by weight of the particles.

[0266] The prepared protective film-forming composition was applied to a thickness of about 3 μm on a lithium metal thin film (having a thickness of about 40 μm) using a doctor blade.

[0267] The coated resultant was dried at a temperature of about 25° C., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com