Waste lithium battery current collector recovery and separation device

A waste lithium battery and separation device technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of low efficiency of manual separation and recycling, and achieve the effect of saving manpower, convenient use and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

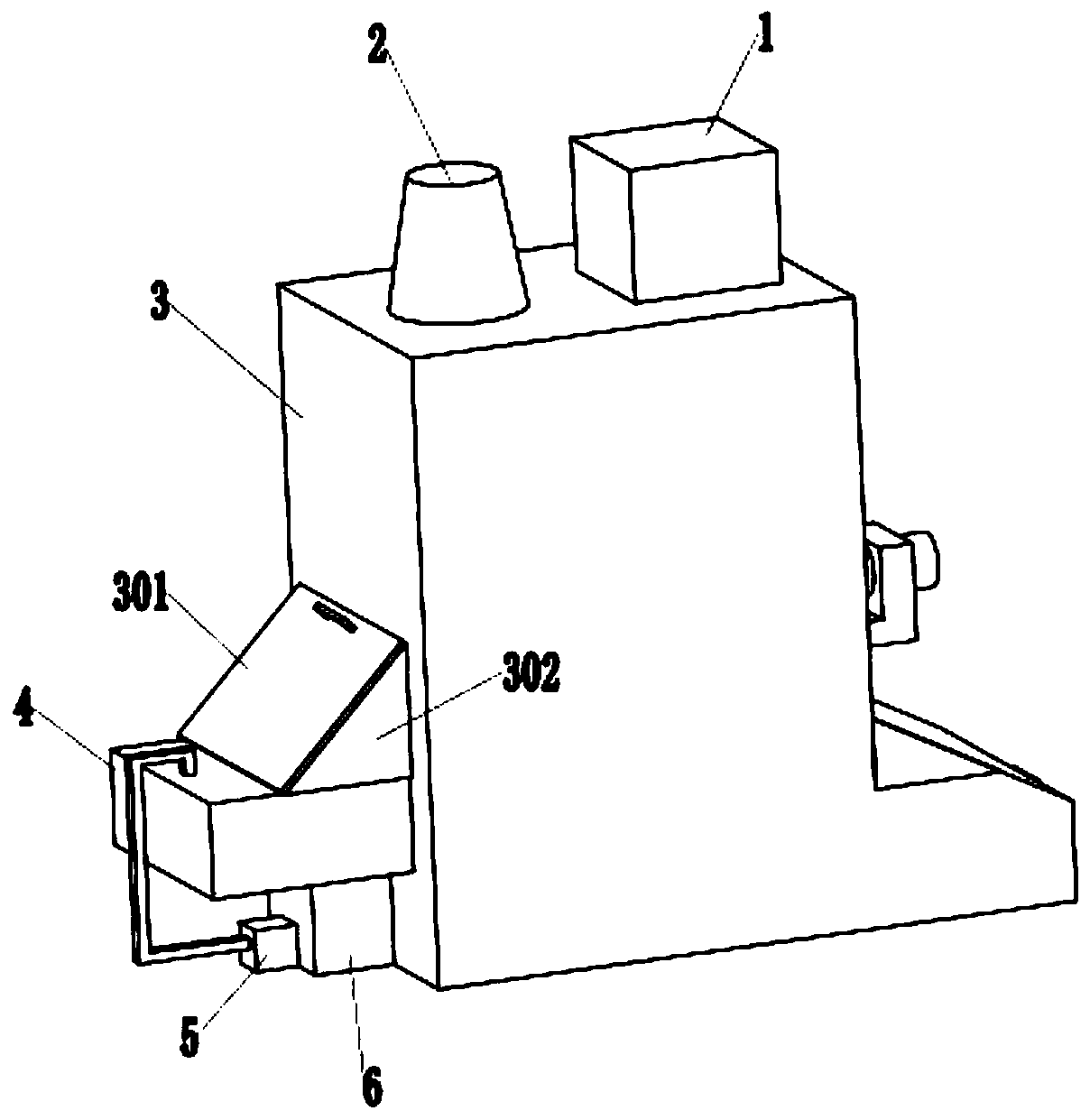

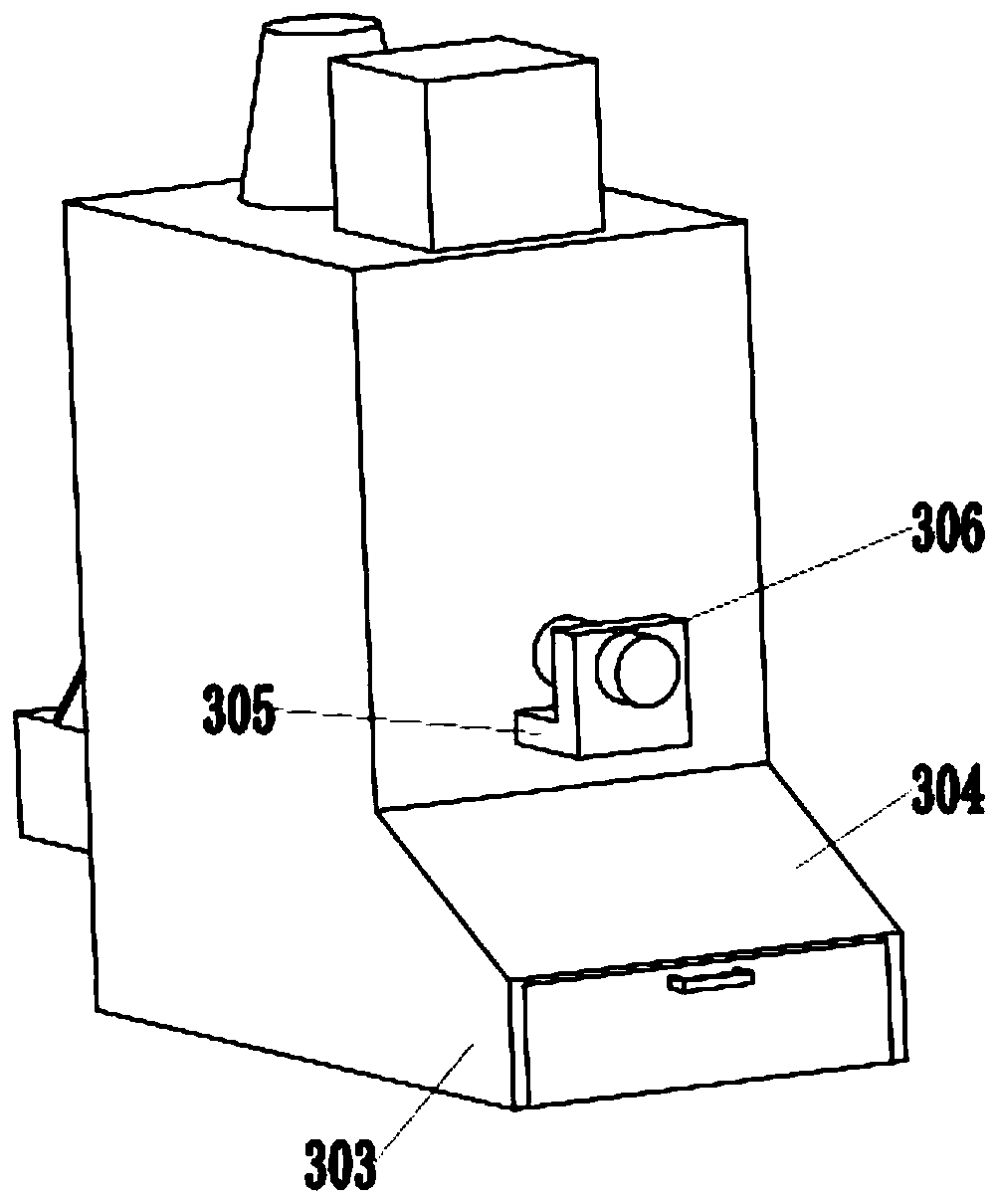

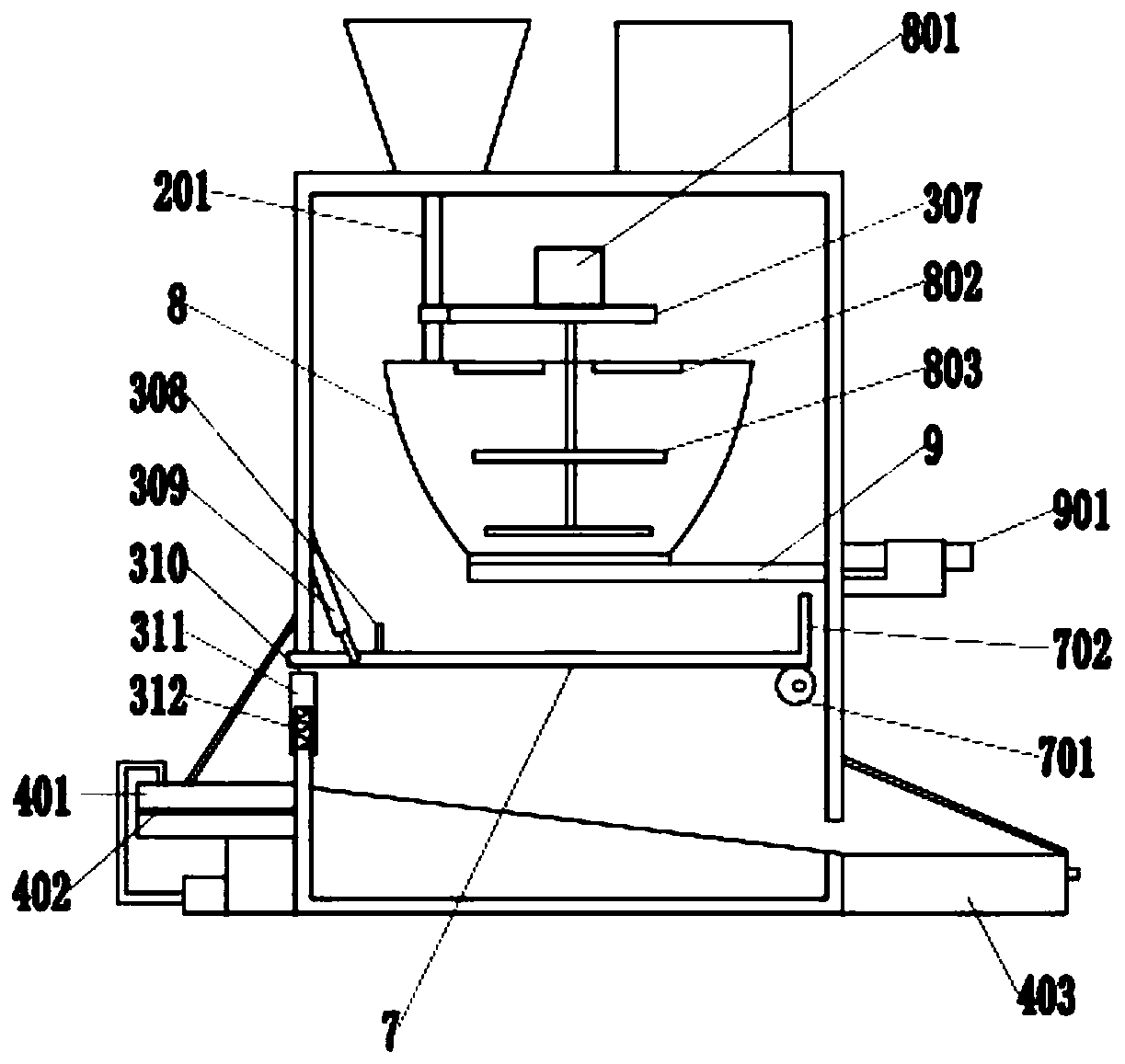

[0029] Such as Figure 1-3 As shown, a waste lithium battery current collector recovery and separation device includes a cutting box 1, a crushing box 2, a casing 3, a collection box 4, and a heating box 8. The upper end of the casing 3 is provided with a cutting box 1 and a crushing box 2, The cabinet 3 is provided with a heating box 8, the crushing box 2 communicates with the heating box 8 through a drop pipe 201, the lower end of the crushing box 2 is provided with a bracket 9, and the bracket 9 is provided with a baffle 905, The baffle plate 905 is connected to the lower end of the heating box 8, and an electric push rod 901 is provided on the outside of the cabinet 3, and the electric push rod 901 is connected to the baffle plate 905, and a sieve plate 7 is provided below the support 9, and the sieve plate A cam 701 is provided under one side of the sieve plate 7, a material blocking plate 702 is provided at the edge of the sieve plate 7, and a limit block 308 connected t...

Embodiment 2

[0031] Such as Figure 1-3 As shown, a waste lithium battery current collector recovery and separation device includes a cutting box 1, a crushing box 2, a casing 3, a collection box 4, and a heating box 8. The upper end of the casing 3 is provided with a cutting box 1 and a crushing box 2, The cabinet 3 is provided with a heating box 8, the crushing box 2 communicates with the heating box 8 through a drop pipe 201, the lower end of the crushing box 2 is provided with a bracket 9, and the bracket 9 is provided with a baffle 905, The baffle plate 905 is connected to the lower end of the heating box 8, and an electric push rod 901 is provided on the outside of the cabinet 3, and the electric push rod 901 is connected to the baffle plate 905, and a sieve plate 7 is provided below the support 9, and the sieve plate A cam 701 is provided under one side of the sieve plate 7, a material blocking plate 702 is provided at the edge of the sieve plate 7, and a limit block 308 connected t...

Embodiment 3

[0034] Such as Figure 1-3As shown, a waste lithium battery current collector recovery and separation device includes a cutting box 1, a crushing box 2, a casing 3, a collection box 4, and a heating box 8. The upper end of the casing 3 is provided with a cutting box 1 and a crushing box 2, The cabinet 3 is provided with a heating box 8, the crushing box 2 communicates with the heating box 8 through a drop pipe 201, the lower end of the crushing box 2 is provided with a bracket 9, and the bracket 9 is provided with a baffle 905, The baffle plate 905 is connected to the lower end of the heating box 8, and an electric push rod 901 is provided on the outside of the cabinet 3, and the electric push rod 901 is connected to the baffle plate 905, and a sieve plate 7 is provided below the support 9, and the sieve plate A cam 701 is provided under one side of the sieve plate 7, a material blocking plate 702 is provided at the edge of the sieve plate 7, and a limit block 308 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com