New energy vehicle charging gun

A technology of new energy vehicles and charging guns, which is applied in the direction of electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of heating of charging guns, achieve the effects of reducing slippage, increasing cooling speed, and improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

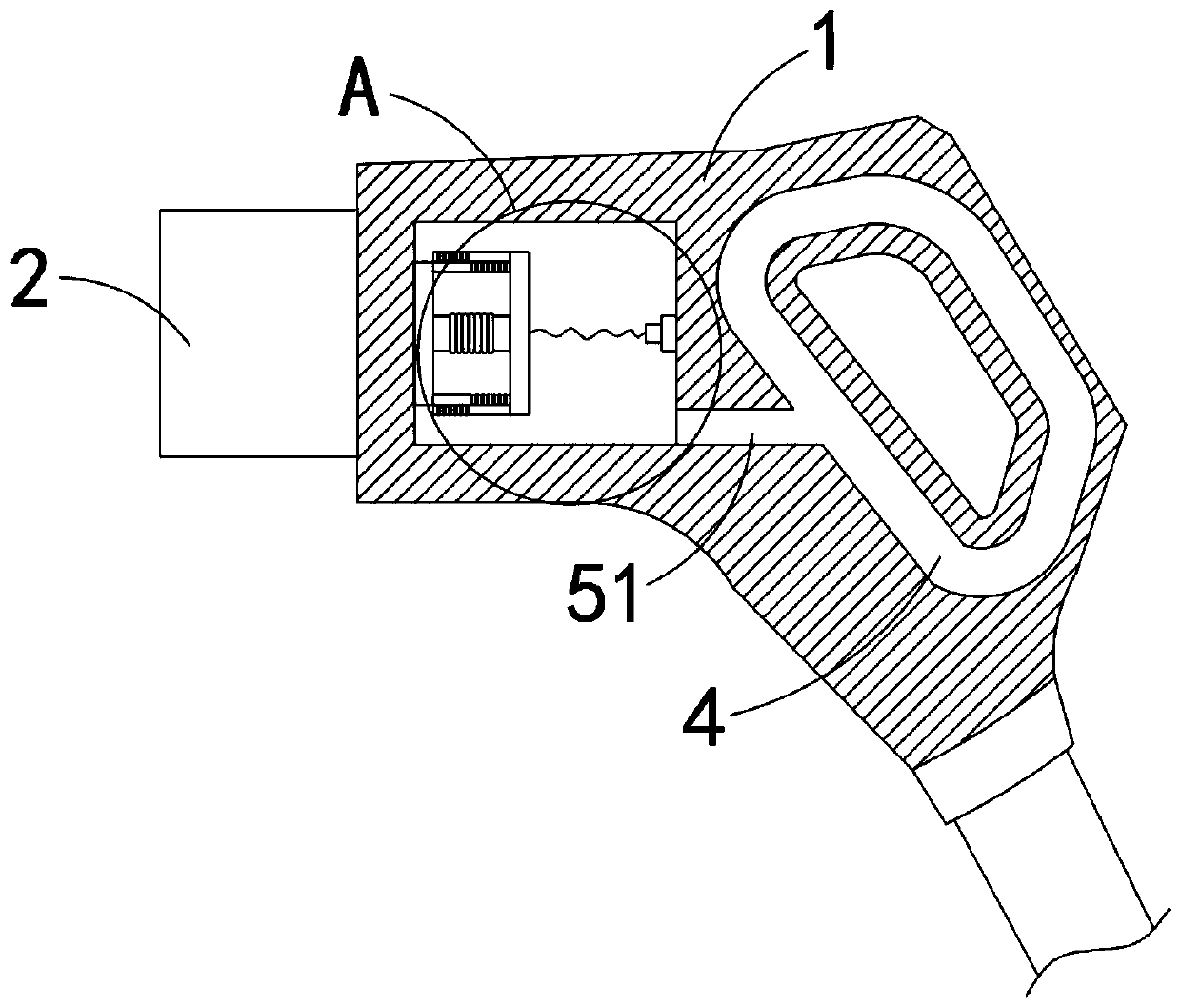

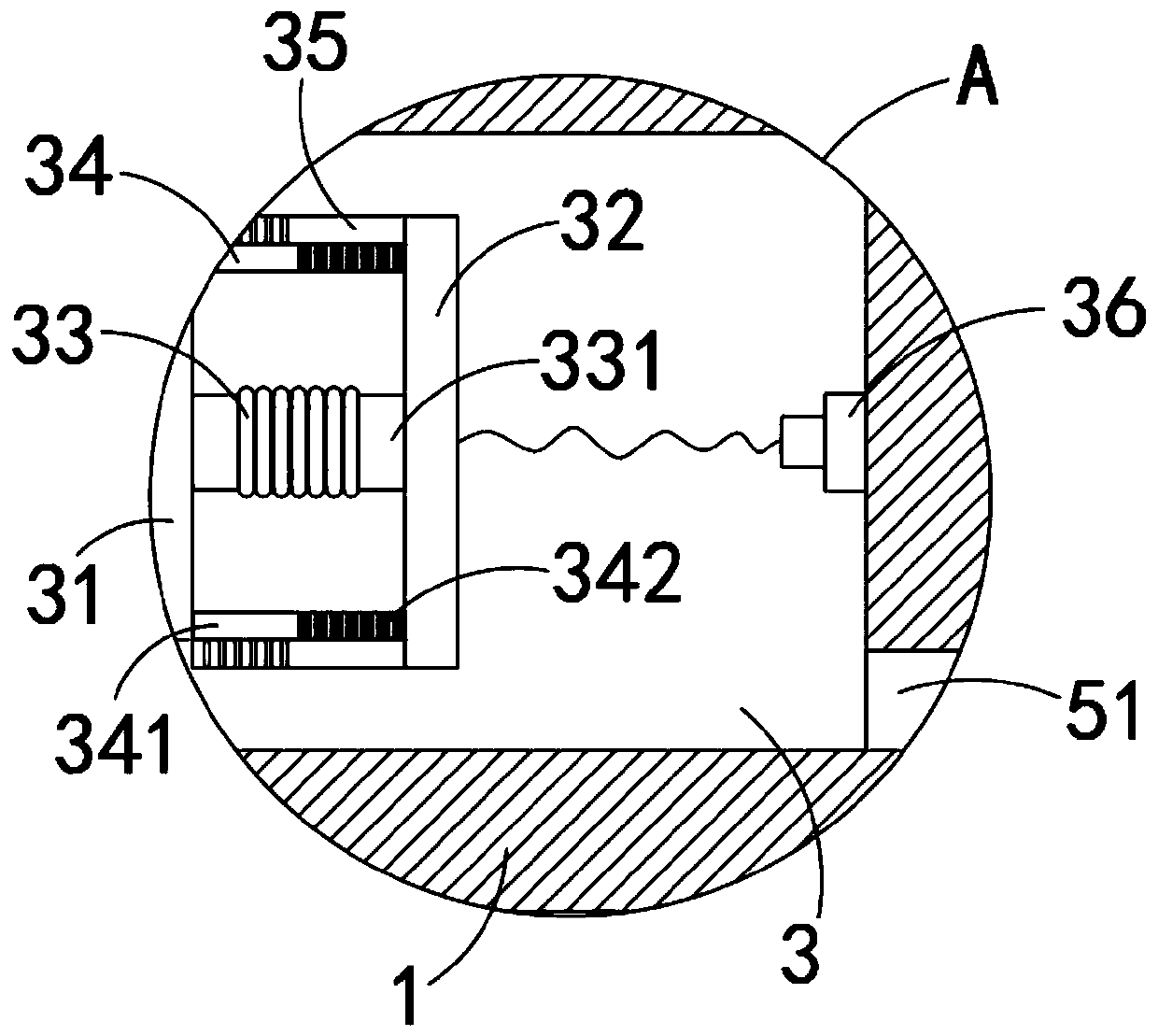

[0034] like Figure 1-5 As shown, a new energy vehicle charging gun includes a gun body 1, the front end of the gun body 1 is fixedly connected with a plug 2, and the gun body 1 is provided with a cavity 3 and a cooling cavity 4, and the cavity 3 and the cooling cavity 4 are filled with There is an insulating liquid, and the insulating liquid can be transformer oil, which can not only play an insulating role, but also cool down the inside of the charging gun. The cavity 3 and the cooling cavity 4 are connected through the connecting channel 51, and the cavity 3 is provided with :

[0035] The conductive plate 31 is fixedly connected to the side wall of the cavity 3, and the conductive plate 31 is electrically connected to the plug 2;

[0036] Movable plate 32, the movable plate 32 is arranged side by side with the conductive plate 31, and the movable plate 32 can move freely along the direction perpendicular to the side wall of the conductive plate 31;

[0037] Memory spring...

Embodiment 2

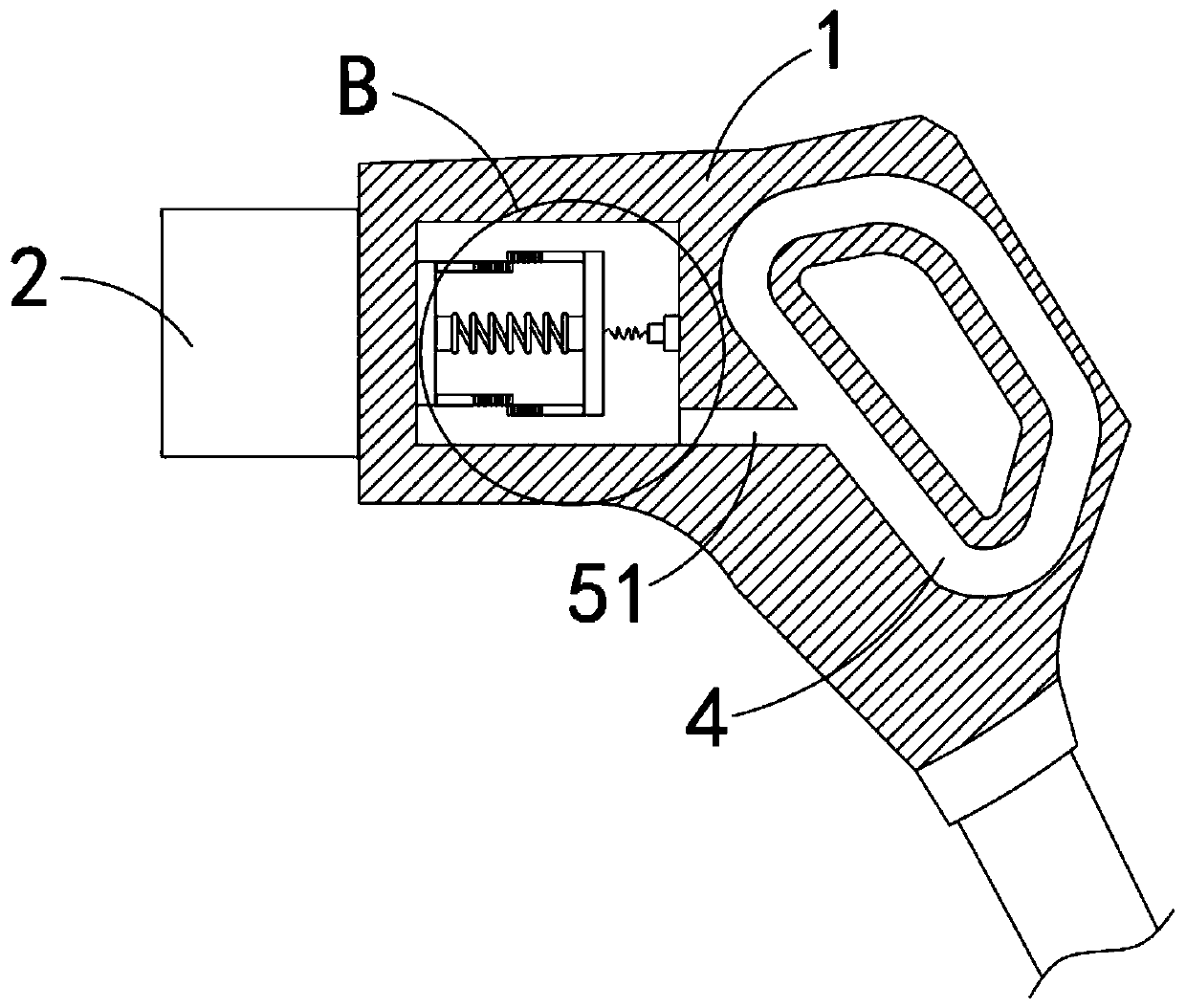

[0044] like Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that the side wall of the movable plate 32 is in sliding and sealed connection with the side wall of the cavity 3, and the two ends of the movable plate 32 are respectively penetrated with a one-way liquid inlet pipe 61 and a The one-way liquid discharge pipe 62, it is worth mentioning that the one-way liquid inlet pipe 61 and the one-way liquid discharge pipe 62 can be realized by a one-way valve, and a circulation channel 52 is provided between the cavity 3 and the cooling chamber 4, and the circulation The passage 52 is in sealing communication with the one-way liquid inlet pipe 61 through the first elastic bellows 611, and the connecting passage 51 is in sealing communication with the one-way liquid discharge pipe 62 through the second elastic bellows 621. It should be noted that the connecting passage 51 is in communication with the cooling cavity The lower part of 4 is connected....

Embodiment 3

[0047] like Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the handle of the gun body 1 is evenly provided with cooling fins 8 .

[0048] In this embodiment, by providing the heat dissipation fins 8, not only the heat dissipation effect on the insulating liquid can be further improved, but also the anti-skid performance of the charging gun can be improved, and the situation of the charging gun slipping can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com