Method for preparing periodic aluminum alloy lattice structure by utilizing 3D printing

A lattice structure, 3D printing technology, applied in the field of 3D printing, can solve the problems of low mechanical properties and non-dense metal matrix structure, so as to reduce costs, reduce trial and error costs, and shorten the design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

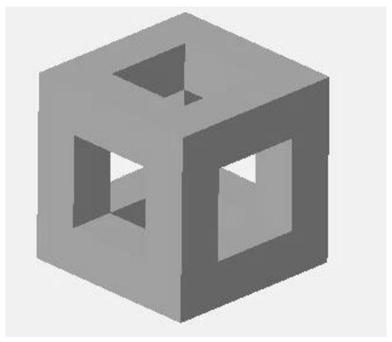

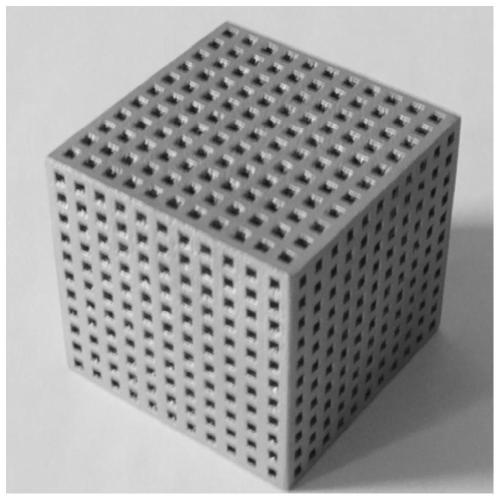

[0069] (1) Select the square lattice structure as the basic unit body, adjust the outline size and distribution, etc., and obtain periodic large square lattice bodies through periodic arrangement, and use 3D software to realize the drawing of the model;

[0070] (2) Purchase aluminum-magnesium alloy powder that conforms to SLM forming, with a particle size distribution of 25-53 μm and good fluidity. Dry it in a vacuum heating furnace before use to prepare for the experiment;

[0071] (3) Use the simulation software to simulate the 3D printing process, in order to avoid errors in the printing process, so as to preliminarily determine the more appropriate printing parameters and powder setting;

[0072] (4) Use 3D printing software to pre-print the designed model, set the model placement position, processing allowance, material parameters, and set printing parameters based on the simulation results, slice processing, etc.;

[0073] (5) Firstly clean the printing room, then compl...

Embodiment 2

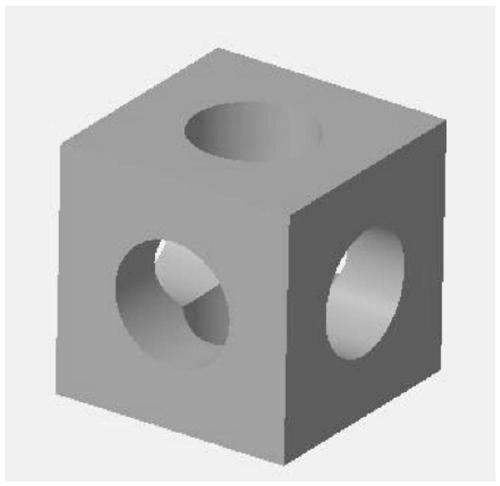

[0079] (1) Select the circular lattice structure as the basic unit body, adjust the outline size and distribution, etc., and obtain a periodic large square lattice body through periodic arrangement, and use 3D software to realize the drawing of the model;

[0080] (2) Purchase aluminum-magnesium alloy powder that conforms to SLM forming, with a particle size distribution of 25-53 μm and good fluidity. Dry it in a vacuum heating furnace before use to prepare for the experiment;

[0081] (3) By simulating the 3D printing process, in order to avoid errors in the printing process, preliminarily determine the more appropriate printing parameters and powder setting;

[0082] (4) Use 3D printing software to pre-print the designed model, set the model placement position, processing allowance, material parameters, and set printing parameters based on the simulation results, slice processing, etc.;

[0083] (5) First clean the printing room, and then complete the powder spreading and su...

Embodiment 3

[0088] (1) Select the rhombus lattice structure as the basic unit body, adjust the outline size and distribution, etc., and obtain a periodic large square lattice body through periodic arrangement, and use 3D software to realize the drawing of the model;

[0089] (2) Purchase aluminum-magnesium alloy powder that conforms to SLM forming, with a particle size distribution of 25-53 μm and good fluidity. Dry it in a vacuum heating furnace before use to prepare for the experiment;

[0090] (3) Use the simulation software to simulate the 3D printing process, in order to avoid errors in the printing process, so as to preliminarily determine the more appropriate printing parameters and powder setting;

[0091] (4) Use 3D printing software to pre-print the designed model, set the model placement position, processing allowance, material parameters, and set printing parameters based on the simulation results, slice processing, etc.;

[0092] (5) Firstly clean the printing room, then comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com