A hand pressure edge banding and cutting machine for sealing bags in the process of chicken essence processing

A technology for processing and sealing bags, which is applied in the field of hand pressure edge sealing and cutting machines, can solve the problems of uneven sealing, insufficient technical considerations, waste, etc., and achieve the effect of improving the quality of heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

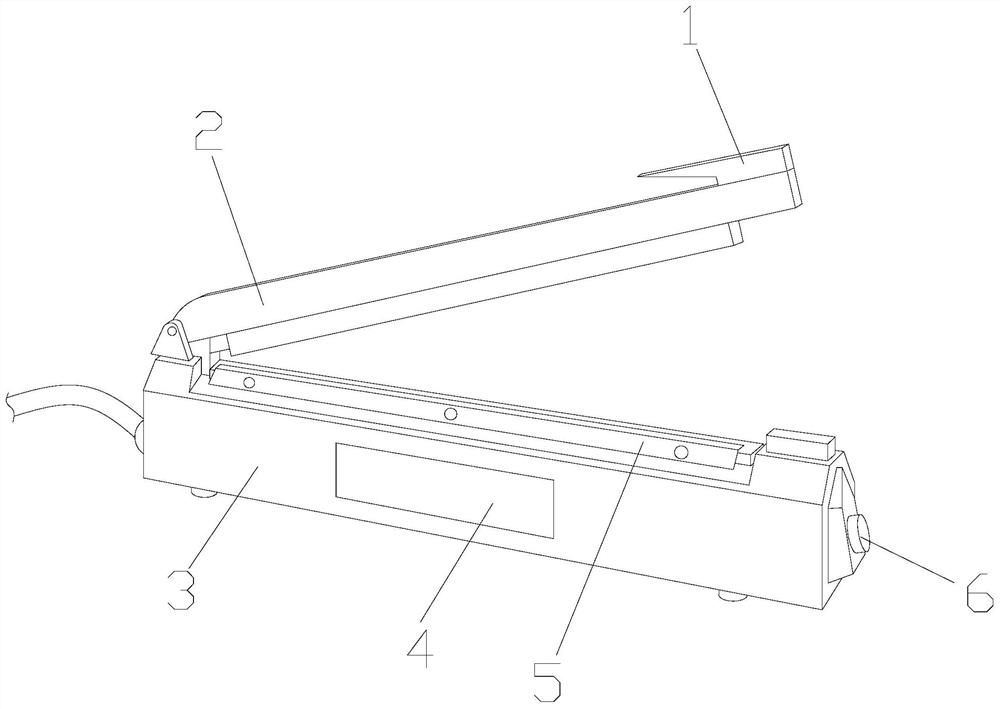

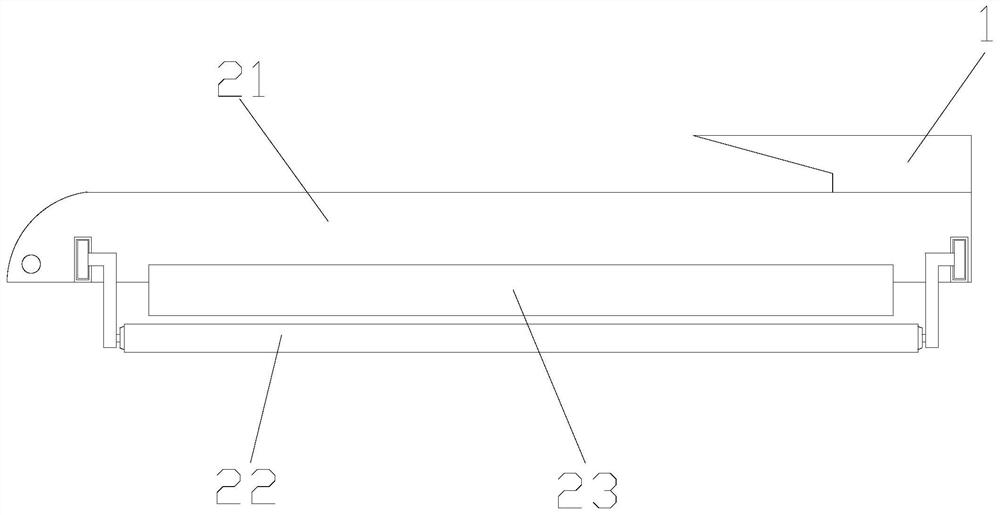

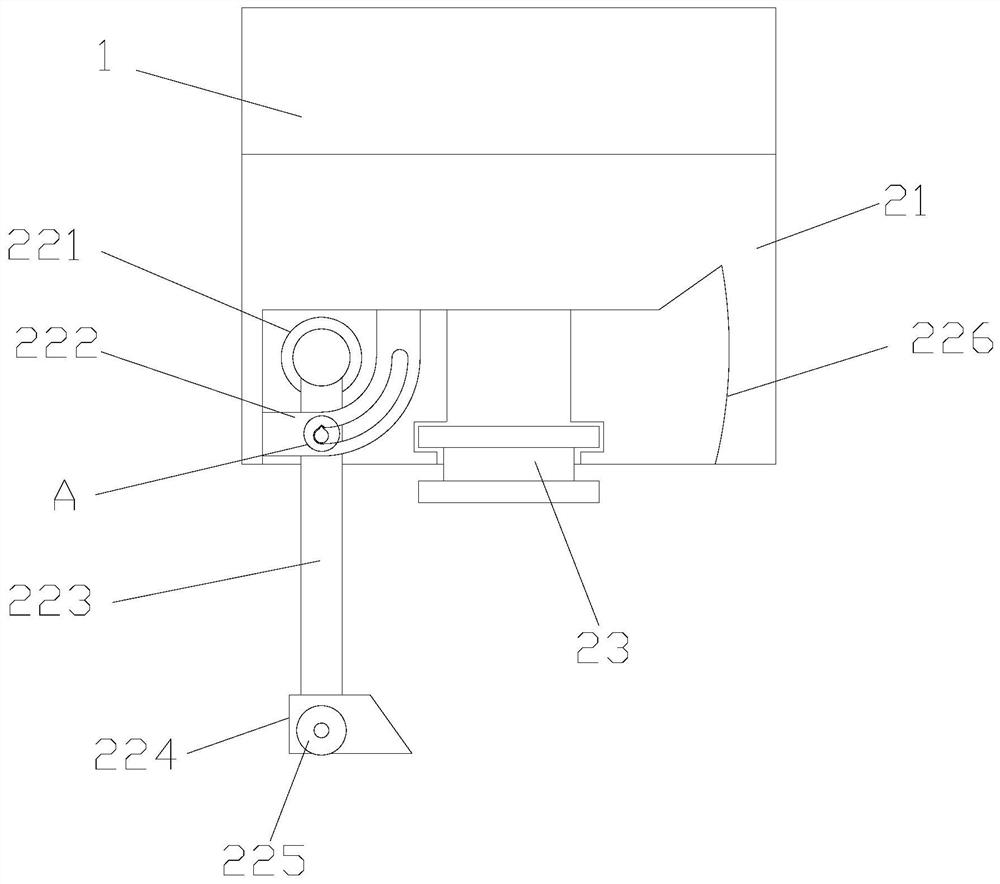

[0030] see Figure 1-Figure 2 , the present invention provides a hand pressure edge banding and cutting machine for sealing bags in the process of chicken finishing, its structure includes a non-slip handle 1, a metal handle seat 2, an edge banding machine main body 3, a product nameplate 4, a metal pressing sheet 5, and a timer Knob 6, the main body 3 of the edge banding machine is placed horizontally on the workbench, the back of the product nameplate 4 is closely attached to the middle of the front of the main body 3 of the edge banding machine, the left end of the timer knob 6 is connected to the right side of the main body 3 of the edge banding machine The side surfaces are fixedly connected by bolts, the leftmost end of the metal handle base 2 is movably connected with the upper left corner of the edge banding machine main body 3 by bolts, the bottom surface of the anti-slip handle 1 is close to the right end of the upper surface of the metal handle base 2, and the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com