A low-shrinkage treatment method, finishing method and device

A processing method and a processing device technology, which are applied in the direction of processing textile material equipment configuration, vibration processing, textile material processing, etc., can solve the problems of low production efficiency and low shrinkage processing can not be continuous production, so as to improve production efficiency and reduce garment production. The difficulty of washing and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Containing low shrinkage processing: singeing, desizing, scouring, bleaching and dyeing, low shrinkage treatment, two pre-shrinking treatments on the high-elastic white grey fabric.

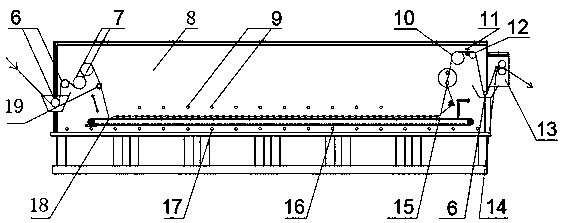

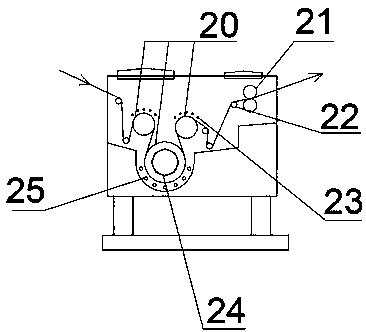

[0128] The low shrinkage treatment process for high elastic fabrics is as follows: the fabric is soaked and rolled dry twice, the rolling pressure is 0.3Mpa, the water temperature is 50°C, and the speed is 50m / min; the wet, boiled, sprayed, and loose stacking treatment is performed twice, and the temperature is Treated at 65°C for 10 minutes; 5 times of low-tension shaking spray washing water treatment, first spray shaking washing water with hot water at a temperature of 80°C, and spray shaking washing water at room temperature for the last section of water tank, shaking roller speed 41r / min, The tension of the gravity induction roll is 12KG; the rolling process is carried out, and the rolling pressure is 0.3Mpa; the drying process is carried out on the setting machine after rolling, the dryin...

Embodiment 2

[0134] The high-elastic yarn-dyed grey fabric is subjected to singeing, desizing, low shrinkage, and two pre-shrinking treatments.

[0135] The low shrinkage treatment process for high-elastic fabrics is as follows: the fabric is immersed and rolled dry once, the rolling pressure is 0.3Mpa, the water temperature is 70℃, and the speed is 70m / min; the wet, boiled, sprayed, and loose stacking treatment is performed once. The temperature is 70℃ for 30 minutes; 3 times of low tension shaking spray washing water treatment, first use the temperature of 75℃ hot water spray shaking washing water, the last section of the water tank is sprayed shaking washing water at room temperature, the shaking roller speed 42r / min, the tension of the gravity induction roll is 13KG; after washing, it is rolled and dried, and the pressure of the rolling cart is 0.3Mpa; after drying, it is dried on the setting machine, the drying temperature is 170℃, and the drying time is 80 seconds.

[0136] Common proces...

Embodiment 3

[0141] The high-elastic denim grey fabric is subjected to singeing treatment, low shrinkage treatment and two pre-shrinking treatments.

[0142] The low shrinkage treatment process for high-elastic fabrics is as follows: the high-elastic fabrics are dipped in the auxiliary agent twice and then rolled dry, at 65℃, the speed is 60m / min, the rolling pressure is 0.3Mpa; the first loose stacking treatment, temperature At room temperature, the treatment time is 10 minutes; the high-elastic fabric is rolled twice to dry; 2 times wet-cooking spray loose stacking treatment, the temperature is 70 ℃ for 10 minutes; 4 times low-tension spray shaking water washing, first Use hot water at a temperature of 75℃ to spray and shake the washing water. The last section of the water tank is shaken and washed under normal temperature conditions. The shaking roller speed is 41r / min, and the gravity induction roller tension is 13KG. It is 0.3Mpa; it is dried in the setting machine, the drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com