Method for determining shape and size of turbine blade anti-corrosion sheet based on CFD analysis

A technology of steam turbine blades and anti-corrosion sheets, which is applied in the field of steam turbines, can solve the problems of poor anti-corrosion effect and inaccurate determination of shape and size, and achieve the effect of improving anti-corrosion effect, reducing quality accident costs, and accurate shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

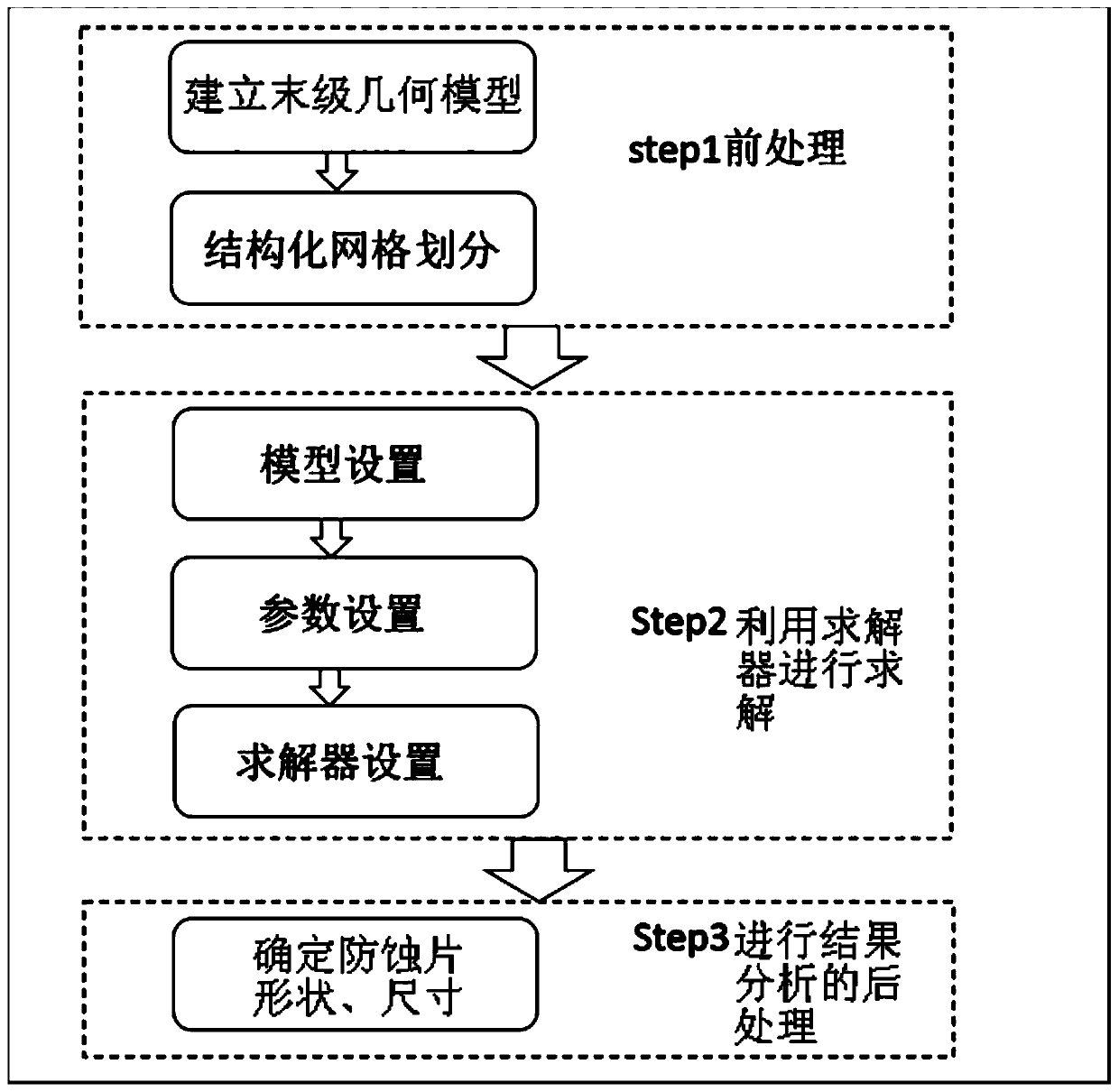

[0034] Specific implementation mode one: combine figure 1 The present embodiment is described. The method for determining the shape and size of the steam turbine blade erosion protection sheet based on CFD analysis provided in the present embodiment specifically includes the following steps:

[0035] (1) Perform pre-processing including numerical modeling and mesh division:

[0036] Firstly, the final geometric model is established based on the flow diagram of the low-pressure cylinder, and then the established final geometric model is imported into the grid division software to divide the structured grid;

[0037] (2) Use the solver to solve:

[0038] Import the grid file of the blade into ANSYS CFX software for model setting (including energy equation, turbulence model, etc.), parameter setting (including working fluid, boundary conditions, etc.). ANSYS CFX is a CFD software; The solver, after setting the discrete format and convergence factor for the solver, iteratively s...

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the specific process of establishing the final geometric model described in step (1) is:

[0042] Prepare the blade data based on the flow diagram of the low-pressure cylinder, and use UG to make the required models for the root of the last-stage stationary blade, the root of the moving blade, and the top expansion angle, and complete the establishment of the last-stage geometric model.

[0043] Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the division process of the structured grid described in step (1) specifically includes:

[0045] Import the established final-level geometric model into the grid division software to divide the structured grid, and encrypt the grid of the blade inlet and outlet arcs. Usually, the grid density is doubled; after division, from the normal The intersection and aspect ratio of grid cells are used to check the quality of the grid.

[0046] Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com