Aerated concrete blank surface slitting device

A technology for aerated concrete and blanks, which is applied in the field of building materials manufacturing, can solve the problems of reduced effective utilization rate of blanks, uneven density of formed blanks, and failure of skin cutting function, and achieves effective utilization improvement, accurate shape and size, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

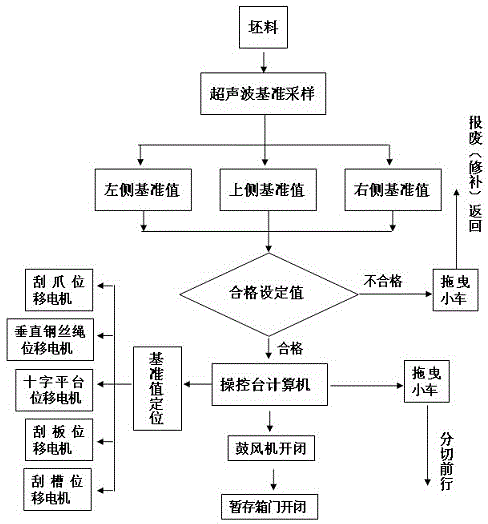

[0034] like figure 1 The shown structure specifically sets forth the implementation mode as the best embodiment of the present invention:

[0035] Force analysis:

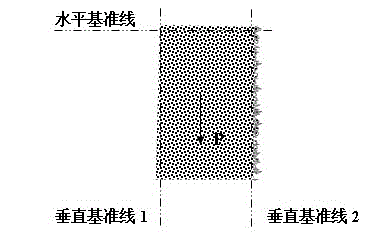

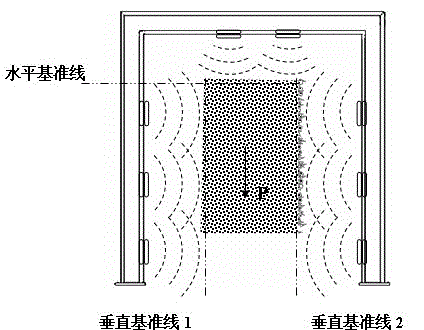

[0036] The aerated concrete body 1 has not been fully cured after being flipped and demolded by the mold at 90°, just like hot bread just out of the oven, so there is a joke in the industry: cutting the aerated concrete body 1 is like cutting bread. . It’s just that this huge bread weighs 4 to 5 tons. The manufacturing process of aerated concrete mainly uses the chemical replacement reaction of metal (Al powder), just like the CO in bread. 2 Foaming function, the main foaming gas in the air-entrained concrete body is H 2 , there are many factors that affect the shape and size of each mold body 1, such as mixing uniformity, temperature, air pressure, and particle uniformity, etc. After the reaction in the mold, the internal density will show that the lower layer is large, the upper layer is small, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com