Mozzarella cheese and preparation technology thereof

A preparation process and cheese technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of time-consuming and laborious monitoring, single color of mozzarella cheese, etc., and achieve the effects of improving stability, ensuring stability and maintaining pink effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

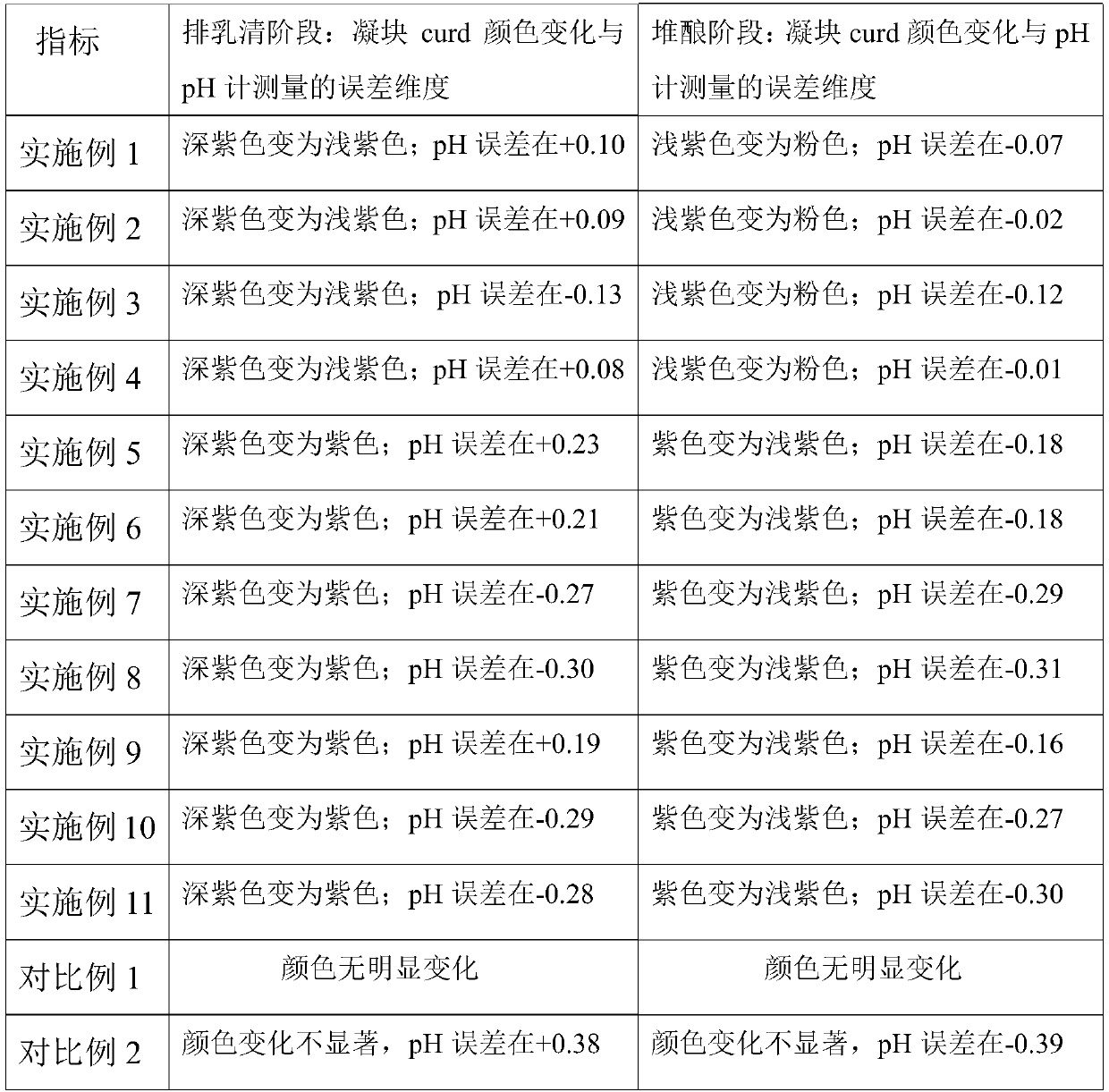

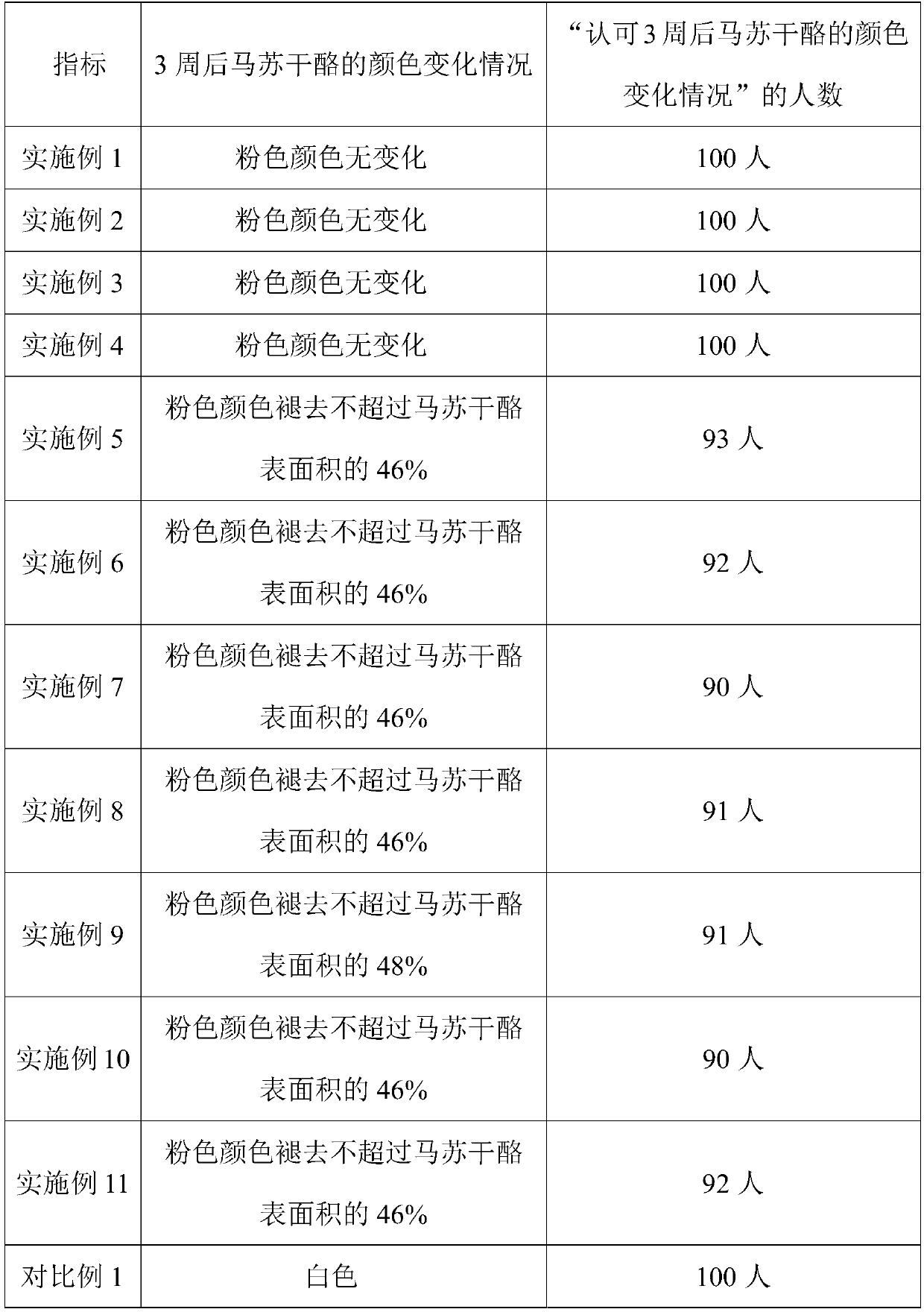

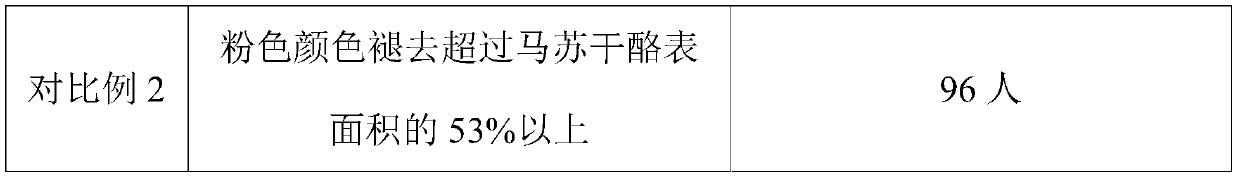

Examples

Embodiment 1

[0039] The present embodiment provides a kind of preparation technology of mozzarella cheese, comprises the following steps:

[0040] (1) Preparation of purple cabbage pigment powder: immerse fresh purple cabbage in the extract solution, the solid-to-liquid ratio of fresh purple cabbage and extract solution is 1g:40mL, and perform ultrasonic extraction, the temperature of ultrasonic extraction is 50°C, the power 26kHz, time is 60min, to obtain the extract, the extract includes edible ethanol and water, the volume ratio of edible ethanol and water is 1.5:8500; the extract is freeze-dried, and the freeze-drying temperature is -23 ℃, the time is 9h, and the purple cabbage pigment powder is prepared;

[0041] (2) Standardized processing of raw milk: Standardized processing of qualified raw milk, the mass ratio of protein to fat in raw milk is 1.1:1;

[0042] (3) Pasteurization, cooling, and filtration: pasteurize, cool, and filter the raw milk in sequence, the pasteurization temp...

Embodiment 2

[0051] The present embodiment provides a kind of preparation technology of mozzarella cheese, comprises the following steps:

[0052] (1) Preparation of purple cabbage pigment powder: immerse fresh purple cabbage in the extract solution, the solid-to-liquid ratio of fresh purple cabbage and extract solution is 1g: 35mL, and perform ultrasonic extraction, the temperature of ultrasonic extraction is 52°C, power 24kHz, time 70min, to obtain the extract, the extract includes edible ethanol and water, the volume ratio of edible ethanol and water is 2:8000; the extract is freeze-dried, and the freeze-drying temperature is -20 ℃, the time is 10h, and the purple cabbage pigment powder is prepared;

[0053] (2) Standardized processing of raw milk: Standardized processing of qualified raw milk, the mass ratio of protein to fat in raw milk is 1.2:1;

[0054] (3) Pasteurization, cooling, and filtration: pasteurize, cool, and filter the raw milk in sequence, the pasteurization temperature...

Embodiment 3

[0063] The present embodiment provides a kind of preparation technology of mozzarella cheese, comprises the following steps:

[0064] (1) Preparation of purple cabbage pigment powder: immerse fresh purple cabbage in the extract solution, the solid-to-liquid ratio of fresh purple cabbage to the extract solution is 1g:45mL, and conduct ultrasonic extraction, the temperature of ultrasonic extraction is 48°C, power 28kHz, time 50min, to obtain the extract, the extract includes edible ethanol and water, the volume ratio of edible ethanol and water is 1:9000; the extract is freeze-dried, and the freeze-drying temperature is -26 ℃, the time is 8h, and the purple cabbage pigment powder is prepared;

[0065] (2) Standardized processing of raw milk: Standardized processing of qualified raw milk, the mass ratio of protein to fat in raw milk is 1.3:1;

[0066] (3) Pasteurization, cooling, and filtration: pasteurize, cool, and filter the raw milk in sequence, the pasteurization temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com