Cheese-free long-shelf-life pizza wiredrawing sauce as well as preparation method and application thereof

A technology of pizza salsa sauce and shelf life, which is applied in the field of seasonings, can solve the problems of easy drawing of pizza, and achieve the effects of strong processability, simple storage conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

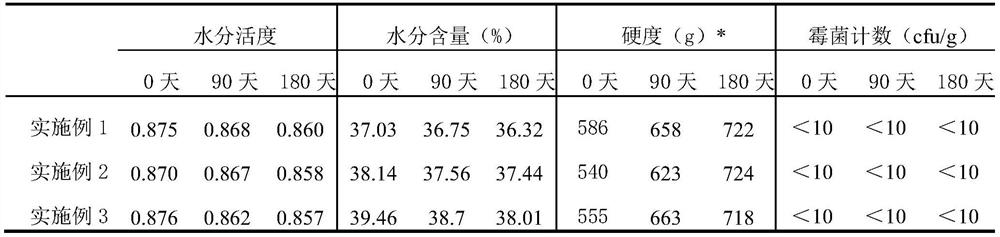

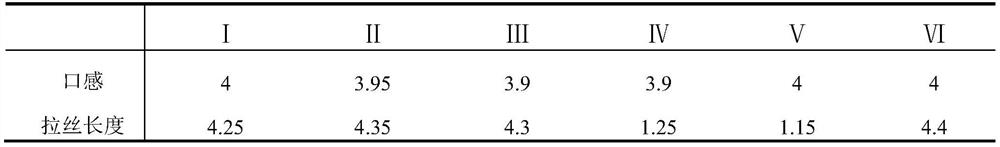

Examples

Embodiment 1

[0053](1) 7.5 kg of hydroxypropyl diphthyl phosphate ester (from 5% by mass by Braser Device, the following example test method is the same, viscosity 2000bu), 0.7kg Proco Sugar (mass percentage 95 % Can pass 60 mesh sieve, the same as), 0.12kg 槐 胶 (viscosity 3000MPa · s), 0.05kg alginate (viscosity 1000MPa · s), 0.4kg citrus fiber, 0.2kg of chicken protein powder and 0.06kg sorbic acid Potassium was mixed, stirred at 20 rpm for 5 minutes, adding 7kg sorbitol liquid (solid content of 70%, lower) and 2.5kg of consumption glycerin (mass percentage greater than 99.5%, the same), stirred at 20 rpm for 5 minutes Mixed material 1.

[0054](2) A mixture of mixture obtained in 20 rpm agitating step (1), 27 kg of sterile distilled water and 46.39 kg of maltose sugar (the solid product content is 80 to 82%, the solid product content) is added to the stirring state. 20 rpm was stirred for 5 minutes, and 8kg edible vegetable oil (soybean oil, the same) was added, and the mixture was obtained at 30...

Embodiment 2

[0058](1) 9.5 kg of hydroxypropyl diphthyl phosphate (viscosity 1700bu), 1.0kg Procolis, 0.18kg Rucopolymeal (viscosity 2500MPa · s), 0.1kg alginate (viscosity 750 MPa · s), 0.5kg of citrus fibers, 0.5 kg of chicken protein powder and 0.08 kg of sorbate were mixed with 25 rpm for 5 minutes, and 10 kg sorbitol liquid and 3.0 kg of consumption glycerol were added, and mixture was stirred at 25 rpm for 5 minutes to obtain a mixture 1.

[0059](2) The mixture of 30 kg of sterile distilled water and 35.04 kg of malt syrup were added under a stirring state, and 10 kg of edible vegetable oil was added to 3200 rpm by stirring at 25 rpm for 5 minutes. The mixture was obtained by the minute.

[0060](3) Steam, the mixture is 2 heated to 90 ~ 95 ° C, and the heat preservation is 25 minutes to the gelation, and the control solid content is 60 to 62%.

[0061](4) Cooling to a temperature of 70 to 75 ° C, adding 0.1 kg of water-free citric acid, stirring at 25 rpm for 5 minutes, cooled to a temperature be...

Embodiment 3

[0063](1) 11.5 kg of hydroxypropyl diphthyl phosphate (viscosity 1400bu), 1.3kg Procolis, 0.24kg Rucopourne Gum (viscosity 2000MPa · S), 0.15 kg of alginate (500 mPa · s), 0.6kg citrus fiber, 0.8 kg of chicken protein powder and 0.1 kg of potassium sorbate were mixed with 30 rpm for 5 minutes, and 13 kg sorbitol liquid and 3.5 kg of glycerol were added to give 30 rpm for 5 minutes to obtain mixture 1.

[0064](2) 33 kg of sterile distilled water and 23.69 kg of malt syrup were added to 30 rpm for 5 minutes at a stirred state of 33 kg of sterile distilled water and 23.69 kg of maltose, and 12 kg edible vegetable oil was added to 3500 rpm. The mixture was obtained by the minute.

[0065](3) Steam, the mixture is 2 heated to 90 ~ 95 ° C, and the insulation is 30 minutes to gelatin, and the control solid content is 60 to 62%.

[0066](4) Cooling to a temperature of 70 to 75 ° C, adding 0.12 kg of waterless citric acid, stirring at 30 rpm for 5 minutes, cooled to a temperature below 50 ° C for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com