Production technology of dark tea

A production process and technology for dark tea, applied in the field of production technology of dark tea, can solve the problems of single taste of dark tea, difficult to like, dark tea affecting appearance and taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of production technology of dark tea, comprises the following steps,

[0032] (1) Picking, picking the delicate tea leaves with white hairs on the back of the leaves, and storing them in the fresh-keeping box;

[0033] (2) Withering, put the tea leaves in the sun for 4 days, and then spread them on a water sieve to dry to room temperature;

[0034] (3) For fermentation, take one-twentieth of the quality of the tea leaves and stack them indoors for 12 hours until the tea leaves turn red, and use them as seasoning ingredients;

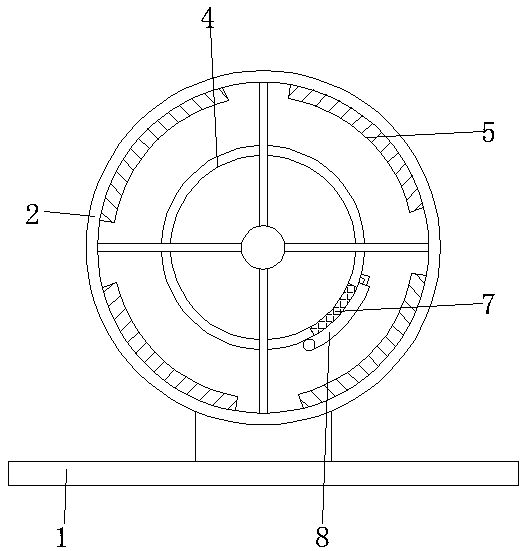

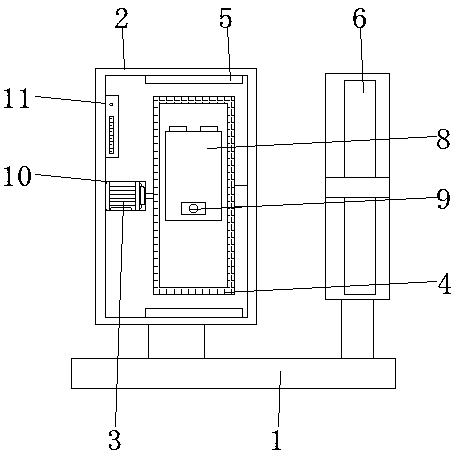

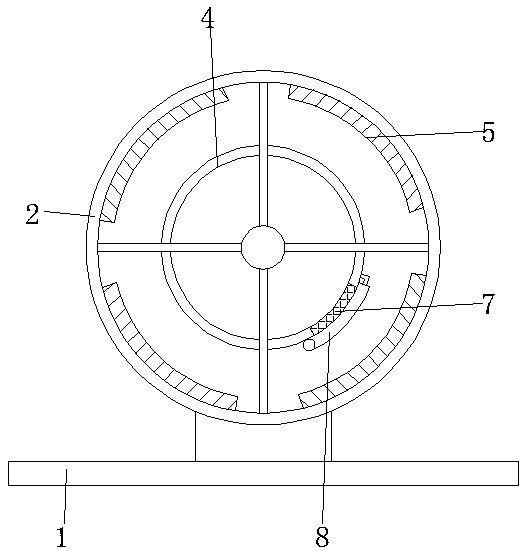

[0035] (4) Baking, put the withered tea leaves and seasonings into the baking device in batches, adjust the baking temperature to 60°C, bake for 10 minutes, and the moisture content of the tea leaves after baking is 4wt%;

[0036] (5) Cooling and packaging. After the tea leaves are cooled, mix the black tea and seasonings evenly, remove the tea leaves with poor shapes, and pack them for storage.

[0037] When the tea leaves are withering,...

Embodiment 2

[0047] A kind of production technology of dark tea, comprises the following steps,

[0048] (1) Picking, picking the delicate tea leaves with white hairs on the back of the leaves, and storing them in the fresh-keeping box;

[0049] (2) Withering, put the tea leaves in the sun for 5 days, and then spread them on a water sieve to dry to room temperature;

[0050] (3) For fermentation, take one-twentieth of the quality of the tea leaves and stack them indoors for 18 hours until the tea leaves turn red, and use them as seasoning ingredients;

[0051] (4) Baking, put the withered tea leaves and seasoning into the baking device in batches, adjust the baking temperature to 70°C, bake for 25 minutes, and the water content of the tea leaves after baking is 5wt%;

[0052] (5) Cooling and packaging. After the tea leaves are cooled, mix the black tea and seasonings evenly, remove the tea leaves with poor shapes, and pack them for storage.

[0053] When the tea leaves are withering, put...

Embodiment 3

[0063] A kind of production technology of dark tea, comprises the following steps,

[0064] (1) Picking, picking the delicate tea leaves with white hairs on the back of the leaves, and storing them in the fresh-keeping box;

[0065] (2) Withering, put the tea leaves in the sun for 6 days, and then spread them on a water sieve to dry to room temperature;

[0066] (3) For fermentation, take one-twentieth of the quality of the tea leaves and stack them indoors for 24 hours until the tea leaves turn red, and use them as seasoning ingredients;

[0067] (4) Baking, putting the withered tea leaves and seasonings into the baking device in batches, adjusting the baking temperature to 80°C, and the baking time lasts for 40 minutes, and the moisture content of the tea leaves after baking is 6wt%;

[0068] (5) Cooling and packaging. After the tea leaves are cooled, mix the black tea and seasonings evenly, remove the tea leaves with poor shapes, and pack them for storage.

[0069] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com