Roller cleaning device of copper strip rolling mill

A technology for cleaning devices and rolls, applied to rolls, keeping roll equipment in an effective state, metal rolling, etc., can solve problems such as large consumption of lubricating oil, poor flushing effect of lubricating oil, and increased cost of strip rolling, and achieve The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

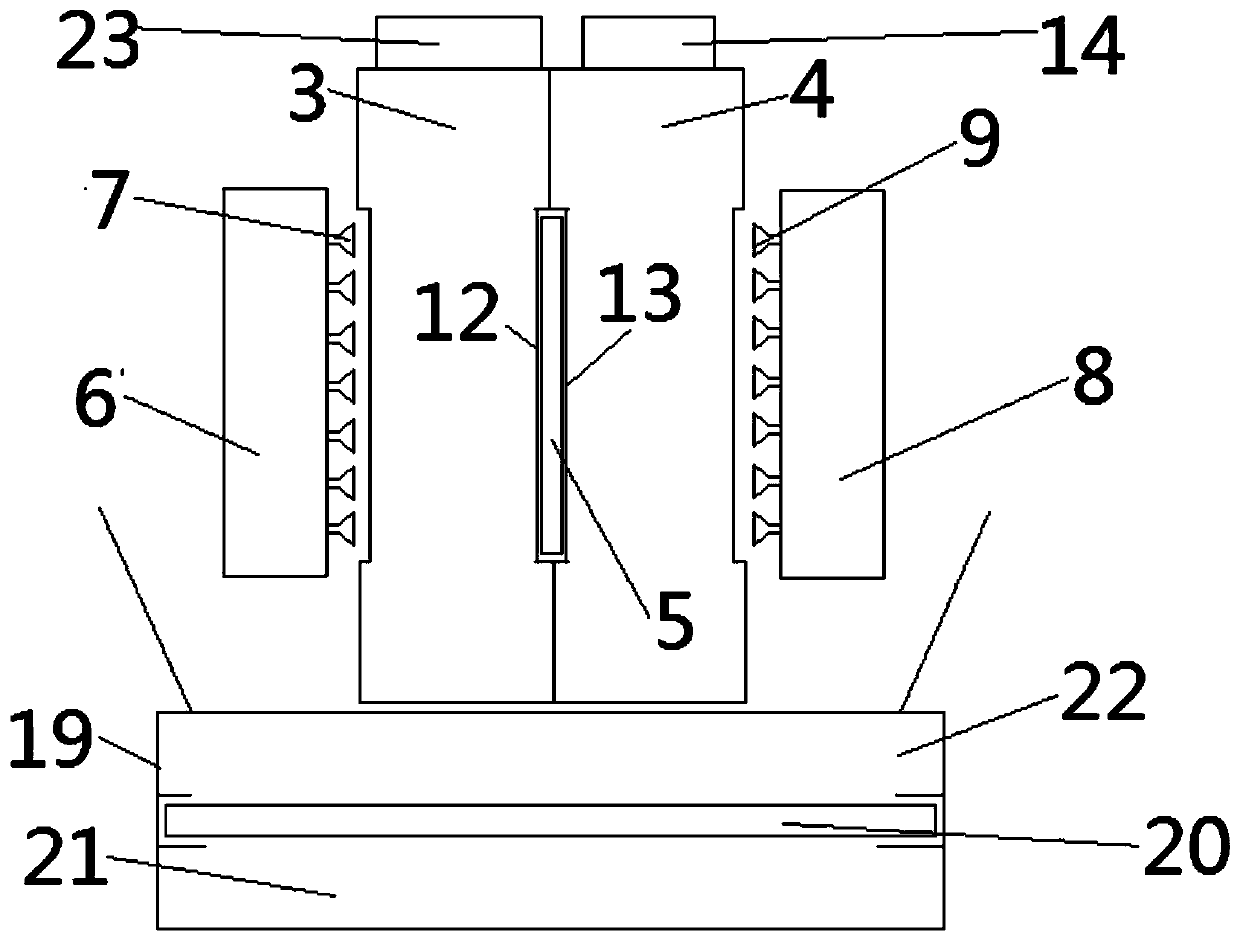

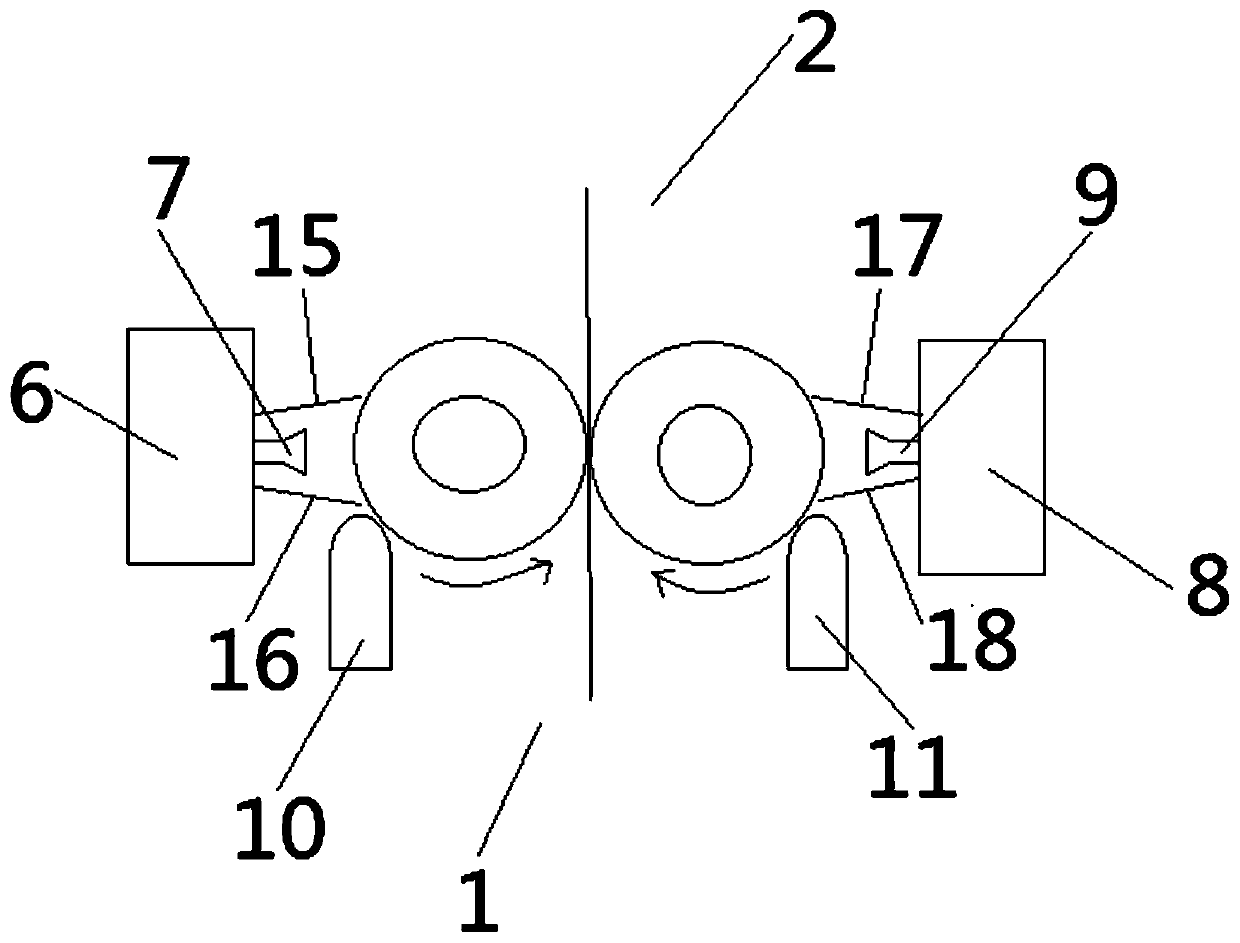

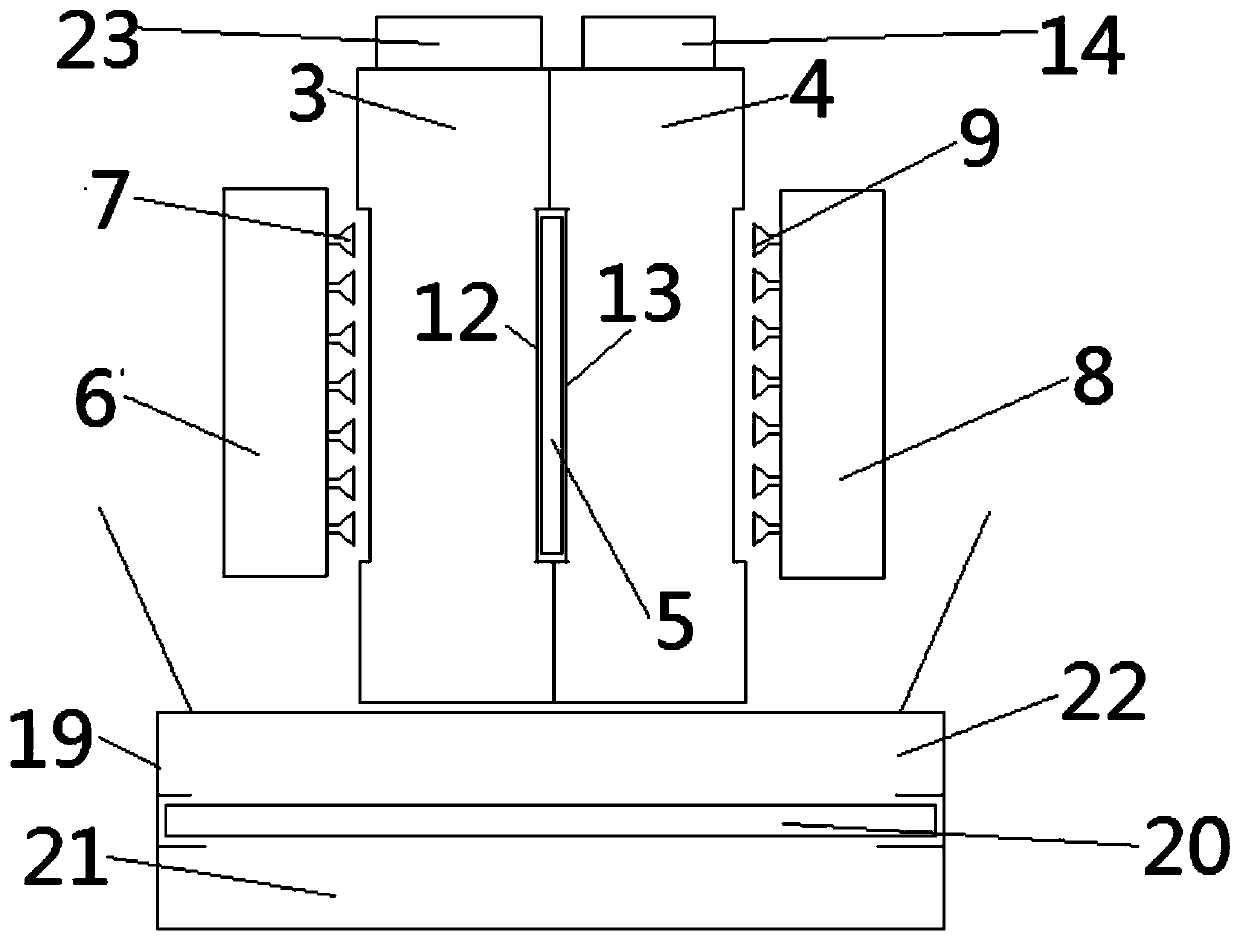

[0019] In the following, referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described. Details of:

[0020] as attached figure 1 , attached figure 2 As shown, the present invention is a copper strip mill roll cleaning device, the copper strip mill roll cleaning device includes a rolling mill body, and the rolling mill body includes a front end side 1 of the rolling mill body and a rear end side 2 of the rolling mill body. The left roll 3 and the right roll 4 are arranged, the left roll 3 and the right roll 4 are both arranged in a vertically arranged structure, and the copper strip substrate 5 is arranged to be able to pass between the left roll 3 and the right roll 4. Rolling to form a copper strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com