Catalyst for hydrodeoxygenation of biomass pyrolysis fluid ebullating bed and its preparation method and application

A biomass pyrolysis and deoxygenation catalyst technology, applied in the field of biomass pyrolysis fluid fluidized bed hydrodeoxygenation catalyst and its preparation, can solve the problems of poor water resistance and acid resistance, unsatisfactory, poor wear resistance, etc. Strength and abrasion resistance, catalyst deactivation prevention, consistent particle size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

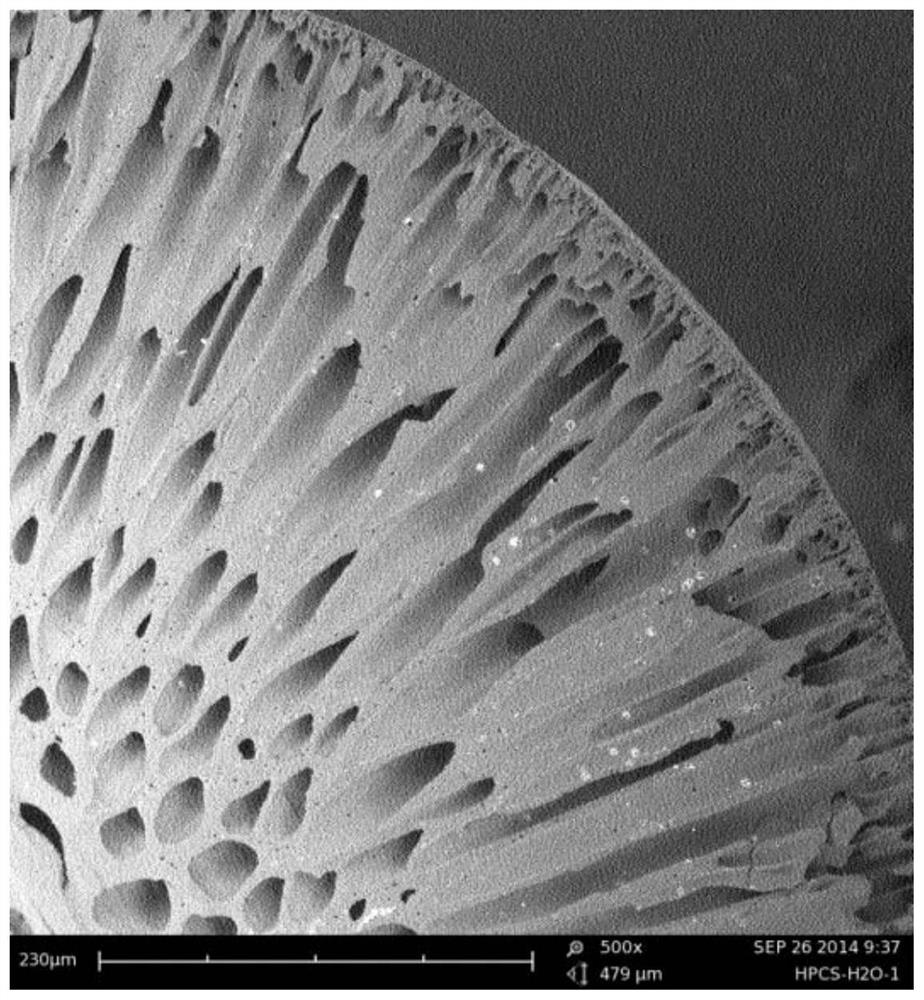

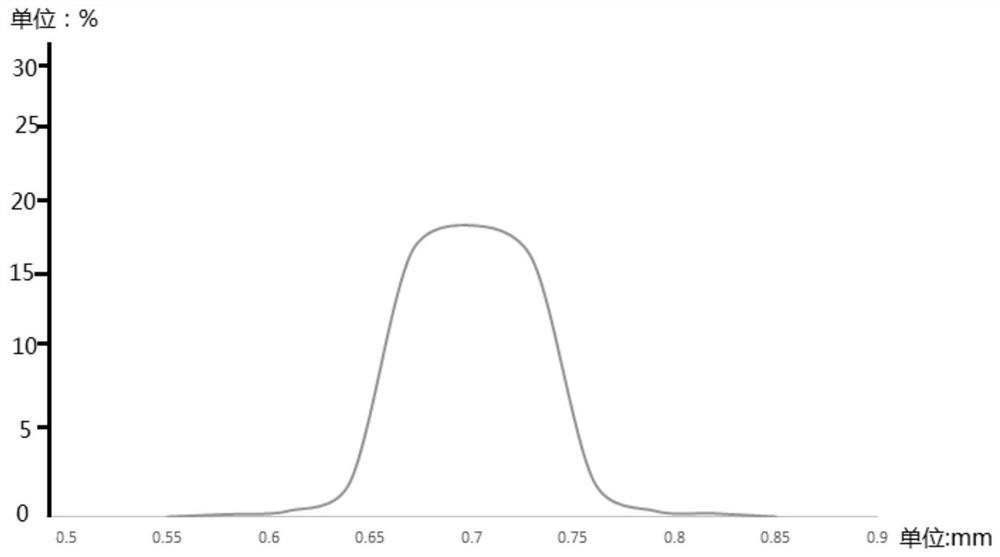

[0042] A solution is formed by dissolving resol resin with a molecular weight of about 50,000 in acetone, and the concentration of the phenol resin in the solution is 20 wt%. The solution is placed in a temperature-controllable container. There are several small cones protruding downwards at the bottom of the container. There are small holes with an inner diameter of 0.2mm in the cone, and the outer diameter of the tip of the cone is 0.6mm. The viscosity of the solution is adjusted by controlling the temperature, and the liquid level in the container is adjusted to adjust the speed of the liquid flowing out of the container, so that the liquid drops along the cone. The forming tank is filled with a certain level of water. The solution containing phenolic resin drops into the forming tank and sinks, and with the gradual precipitation of acetone, the phenolic resin solidifies when it meets water to form porous spherical particles.

[0043] The spherical particles are washed wit...

Embodiment 2

[0046] Polyacrylonitrile with a molecular weight of about 30,000 is dissolved in N,N-dimethylformamide (abbreviated as DMF) to form a solution, and the concentration of polyacrylonitrile in the solution is 18 wt%. The solution is placed in a temperature-controllable container. There are several small cones protruding downwards at the bottom of the container. There are small holes with an inner diameter of 0.2mm in the cone, and the outer diameter of the tip of the cone is 0.6mm. The viscosity of the solution is adjusted by controlling the temperature, and the liquid level in the container is adjusted to adjust the speed of the liquid flowing out of the container, so that the liquid drops along the cone. The forming pool is filled with ethanol aqueous solution with a certain liquid level, and the ethanol concentration is 15%. The polyacrylonitrile-containing solution drops into the forming pool and sinks, and with the gradual precipitation of DMF, the polyacrylonitrile solidifi...

Embodiment 3

[0050] Polyacrylonitrile with a molecular weight of about 80,000 was dissolved in DMF to form a polymer solution with a polyacrylonitrile concentration of 12 wt%. Other operations were the same as in Example 2 to obtain a carbon-based carrier.

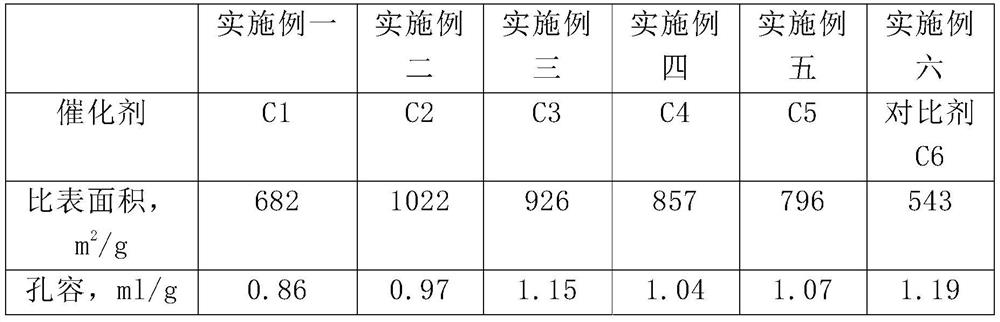

[0051] Put 100 grams of carbon-based carrier in the drum, spray 97ml of water in which active metal components nickel 9.1wt% and manganese 4.5wt% are dissolved, and then dry at 120°C for 3 hours; Roast under protection for 4 hours, and the calcining temperature is 500°C. Catalyst C3 is prepared. The relevant parameters of catalyst C3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com