Multi-chamber aluminum electrolytic cell and its busbar system

An aluminum electrolytic cell and busbar system technology, applied in the field of aluminum electrolysis, can solve the problems of complex structure, instability and high cost of the busbar system, and achieve the effects of significant energy saving, poor stability and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

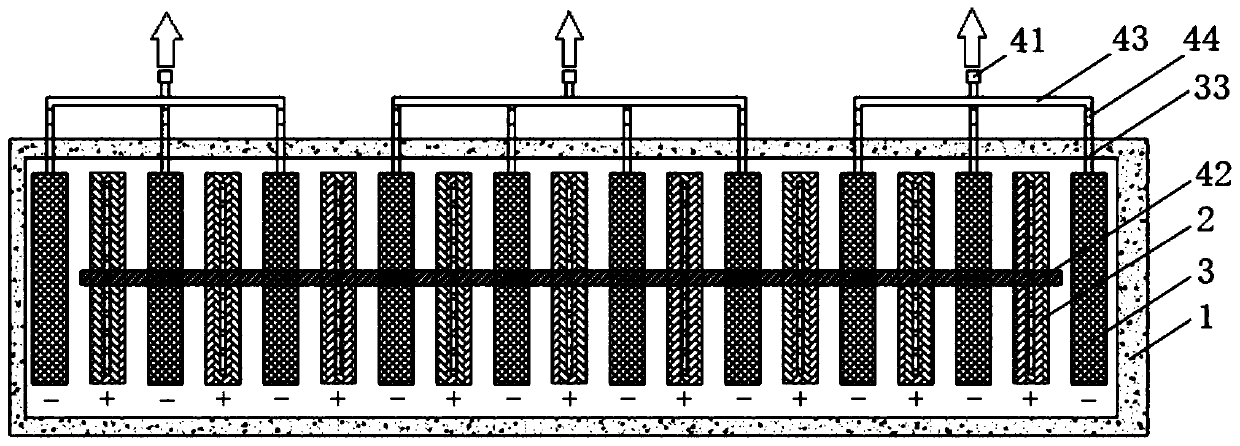

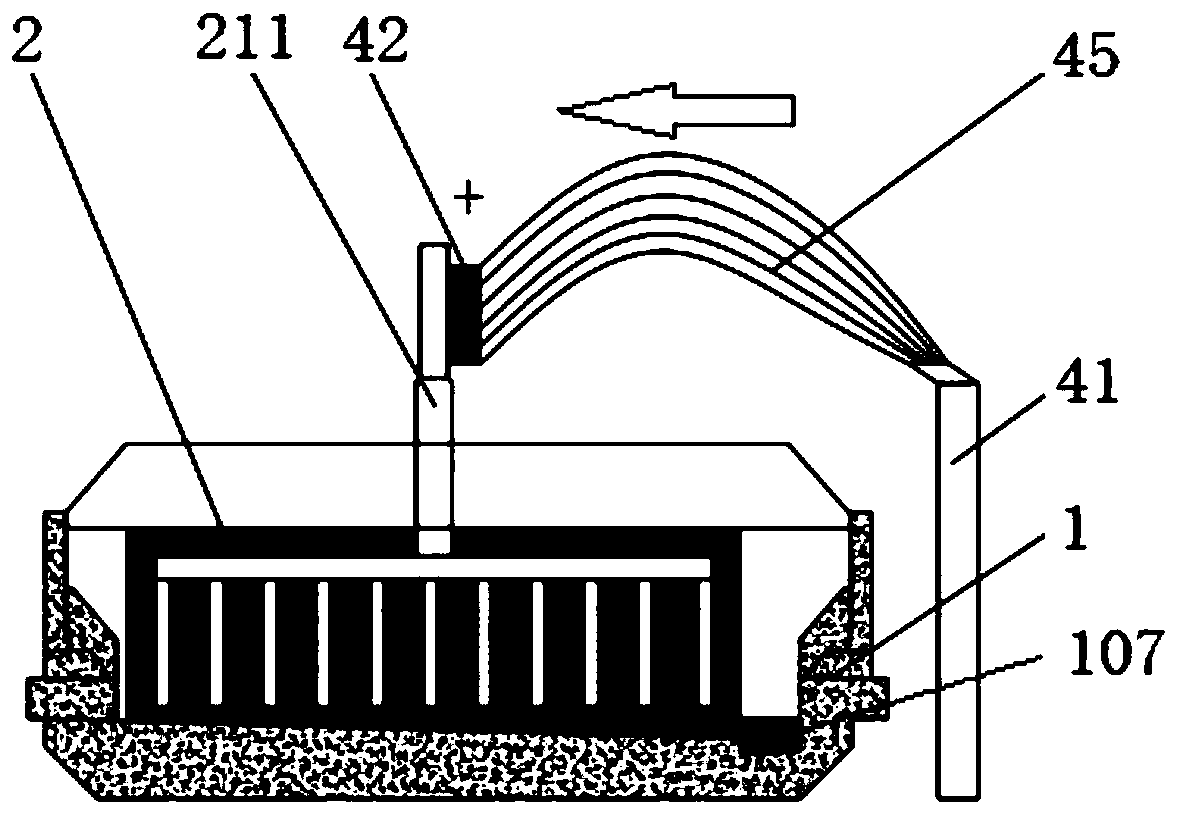

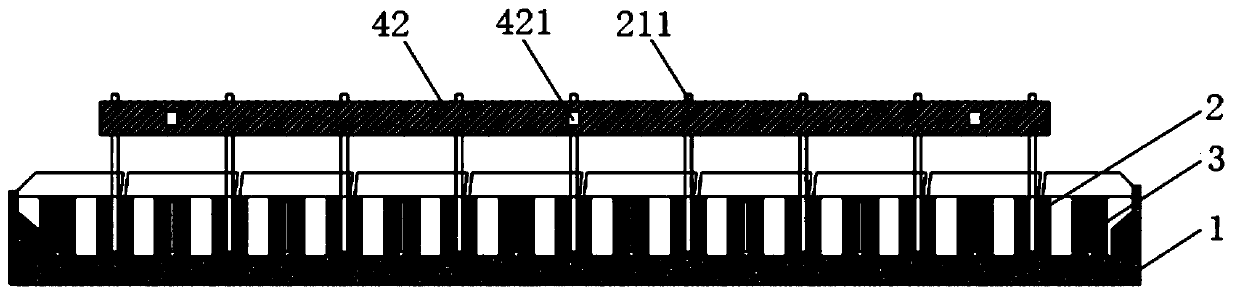

[0028] see Figure 1-3 , the multi-chamber aluminum electrolytic cell shown in the figure is a preferred embodiment of the present invention, specifically including a cell body 1 and several groups of anodes 2 and several groups of cathodes 3 arranged alternately inside the cell body 1, and the anodes 2 and cathodes 3 are all made of the same The size of the plate electrode structure, adjacent anodes 2 and cathodes 3 are vertically arranged and form parallel electrolytic chambers, and at least two such electrolytic chambers are formed in the tank body 1 of the entire electrolytic cell along the horizontal direction. The bottom surface of the cell body 1 of the electrolytic cell is inclined to one side, and a polyaluminum groove 107 that is recessed relative to the bottom surface of the cell body is provided on the lower side. The electrolyte in the electrolysis chamber between the anode 2 and the cathode 3 is vertically electrolyzed, and the electrolysis produces The molten al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com