Device and application process for improving the quality of cotton web of aramid nonwoven fabric

A technology of non-woven fabrics and cotton nets, which is applied in the field of devices for improving the quality of aramid non-woven fabrics and cotton nets. It can solve the problems of poor static electricity removal and damage to product quality, so as to achieve the goal of not being easily damaged, improving product quality, and preventing product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

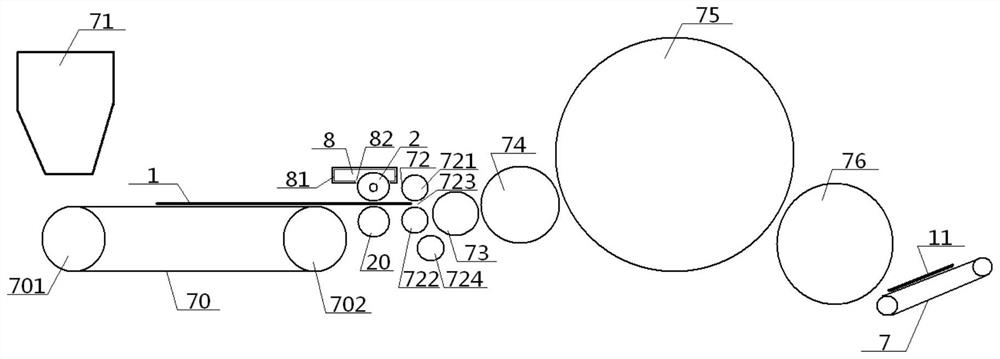

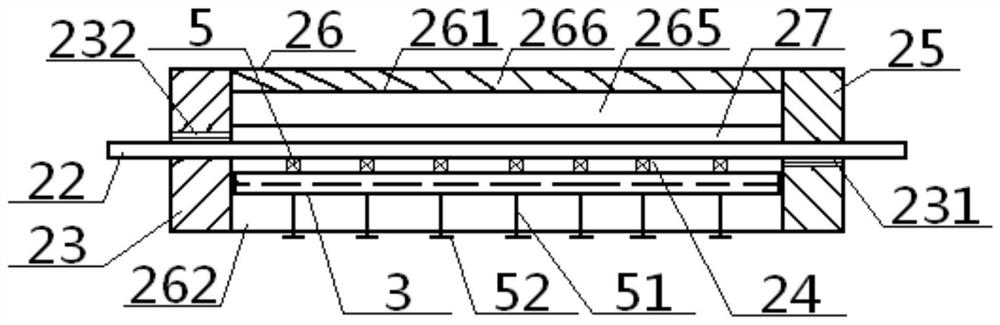

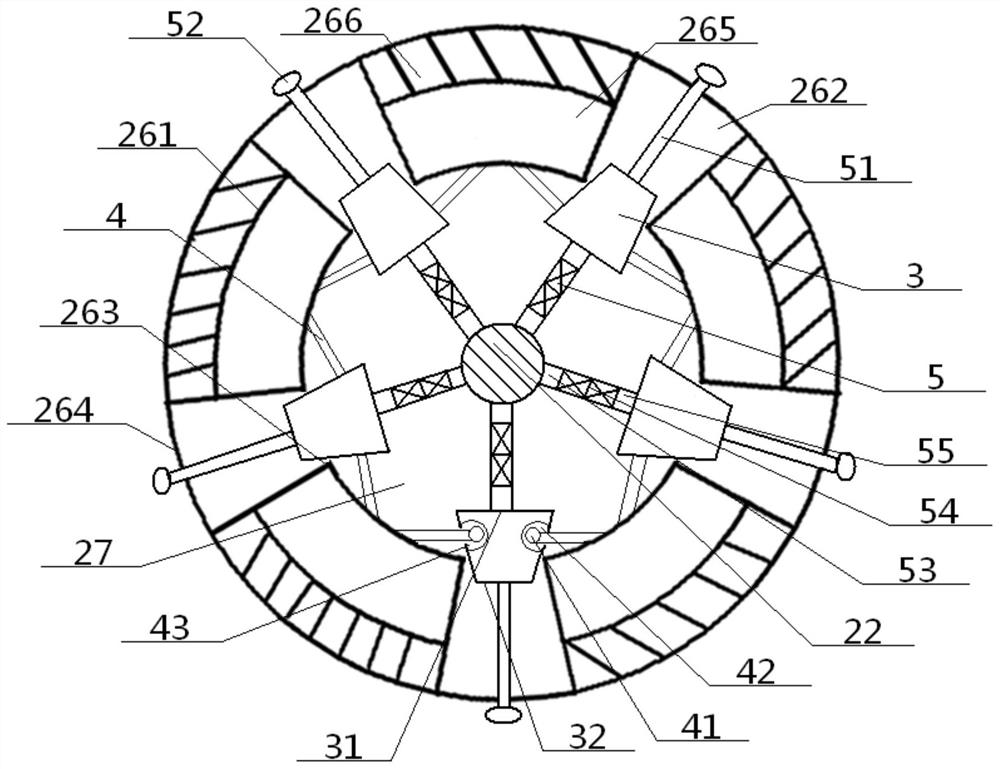

[0057] see figure 1 ― Figure 9, a device for improving the quality of aramid non-woven fabric cotton web, including a hopper 71, a horizontal feeding curtain 70, a feeding roller 72, a humidifying roller 2 and a lower driving roller 20, the horizontal feeding curtain 70 The two ends are respectively provided with a front curtain roller 701 and a rear curtain roller 702. The feeding roller 72 includes an upper feeding roller 721, a lower feeding roller 722 and a feeding port 723 sandwiched between them. The feeding port of 70 and the bottom end of the hopper 71 are set facing each other. 7 are connected; the humidifying roller 2 includes a humidifying roller 21 and a roller shaft 22 passing through the middle thereof, and the humidifying roller 21 includes a middle rolling portion 24 and a left roller end connected to both ends thereof. 23. Right roller end portion 25, the middle roller pressing portion 24 includes a roller outer body 26 and a roller middle cavity 27, the ro...

Embodiment 2

[0060] The basic content is the same as that of Example 1, except that:

[0061] The hollow fan block 262 is a fan-shaped structure with a narrow top and a wide bottom; the cross section of the movable block 3 is a trapezoidal structure with a wide top and a narrow bottom, including the top side 31 of the block, the bottom side 32 of the block, and the top side of the block. The widths of the side 31 , the inner port 263 , the bottom side 32 of the block, the contact head 52 , and the upper top rod 51 are successively reduced.

Embodiment 3

[0063] The basic content is the same as that of Example 1, except that:

[0064] The two sides of the movable block 3 are respectively connected with the top end of the telescopic bar 4 , and the bottom end of the telescopic bar 4 is connected with the top of the solid sector block 261 on the side of the movable block 3 . The side part of the movable block 3 is provided with a movable ball cavity 42 with a one-way opening. The movable ball 41 set in the movable ball cavity 42 is connected with the top end of the telescopic strip 4, and the bottom end of the telescopic strip 4 passes through the ball cavity opening. After 43, it is connected to the top of the solid sector block 261, and the diameters of the movable ball cavity 42, the movable ball 41, the ball cavity opening 43, and the telescopic strip 4 are successively reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com