Concentric pipe integration one-way valve heating device for crankcase ventilation system

A crankcase ventilation and heating device technology, applied in the field of auto parts, can solve the problems of clogging check valves, energy loss, and high crankcase pressure, prevent frost crystals and icing, reduce after-sales maintenance costs, and improve layout The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

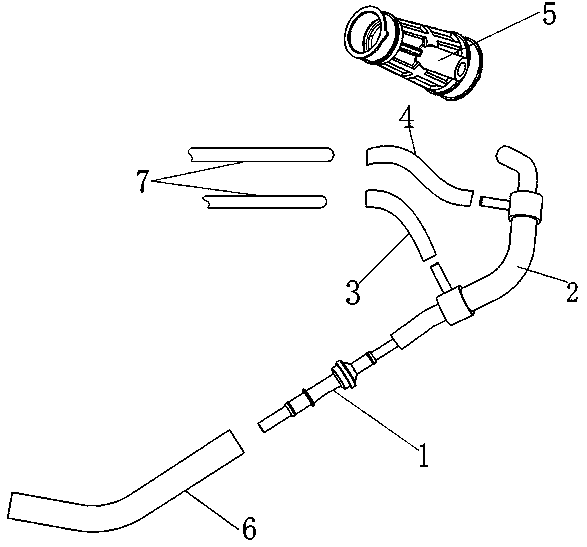

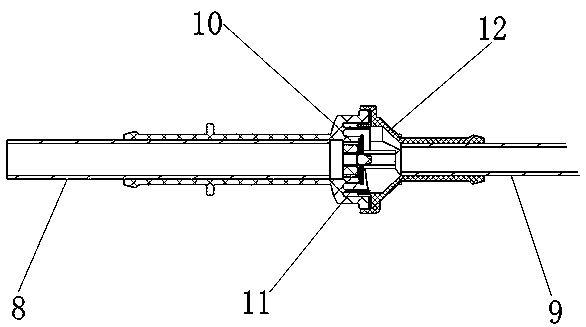

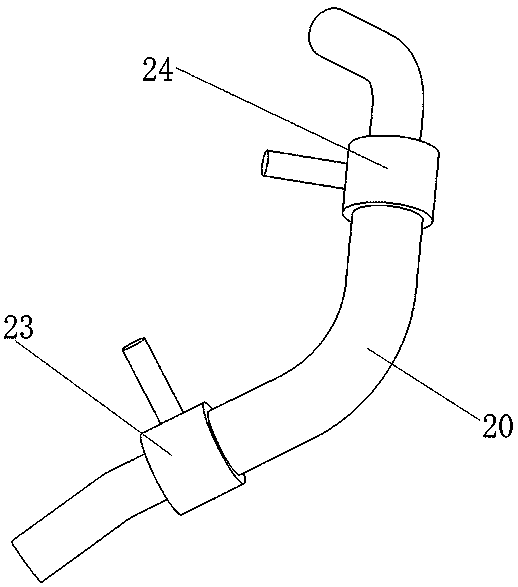

[0022] see Figure 1 to Figure 4 As shown, a crankcase ventilation system integrates a one-way valve heating device with a co-core tube, including a one-way valve 1, a co-core tube 2, a liquid inlet tube 3, a liquid outlet tube 4, an inlet tube interface 5, and a crankcase ventilation tube 6. The engine supercharger coolant outlet pipe 7, the first embedded aluminum tube 8 and the second embedded aluminum tube 9, one end of the liquid inlet pipe 3 and one end of the liquid outlet pipe 4 are respectively connected with the coolant outlet of the engine supercharger. The water pipe 7 is connected and one end of the liquid inlet pipe 3 and the other end of the liquid outlet pipe 4 are respectively connected with the same core pipe 2 to form a coolant circulation path in series, and one end of the crankcase ventilation pipe 6 is connected to the single pipe through the first embedded aluminum pipe 8. One end of the valve 1 is connected, the other end of the one-way valve 1 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap