Magnetic isolation and heat dissipation protection cover of hydraulic cylinder and magnetic isolation and heat dissipation method thereof

A hydraulic cylinder and protective cover technology, applied in the field of hydraulic cylinders, can solve the problems of hydraulic cylinder heating, failure, and shortened hydraulic cylinder life, and achieve the effects of reducing working temperature, prolonging working life, and avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

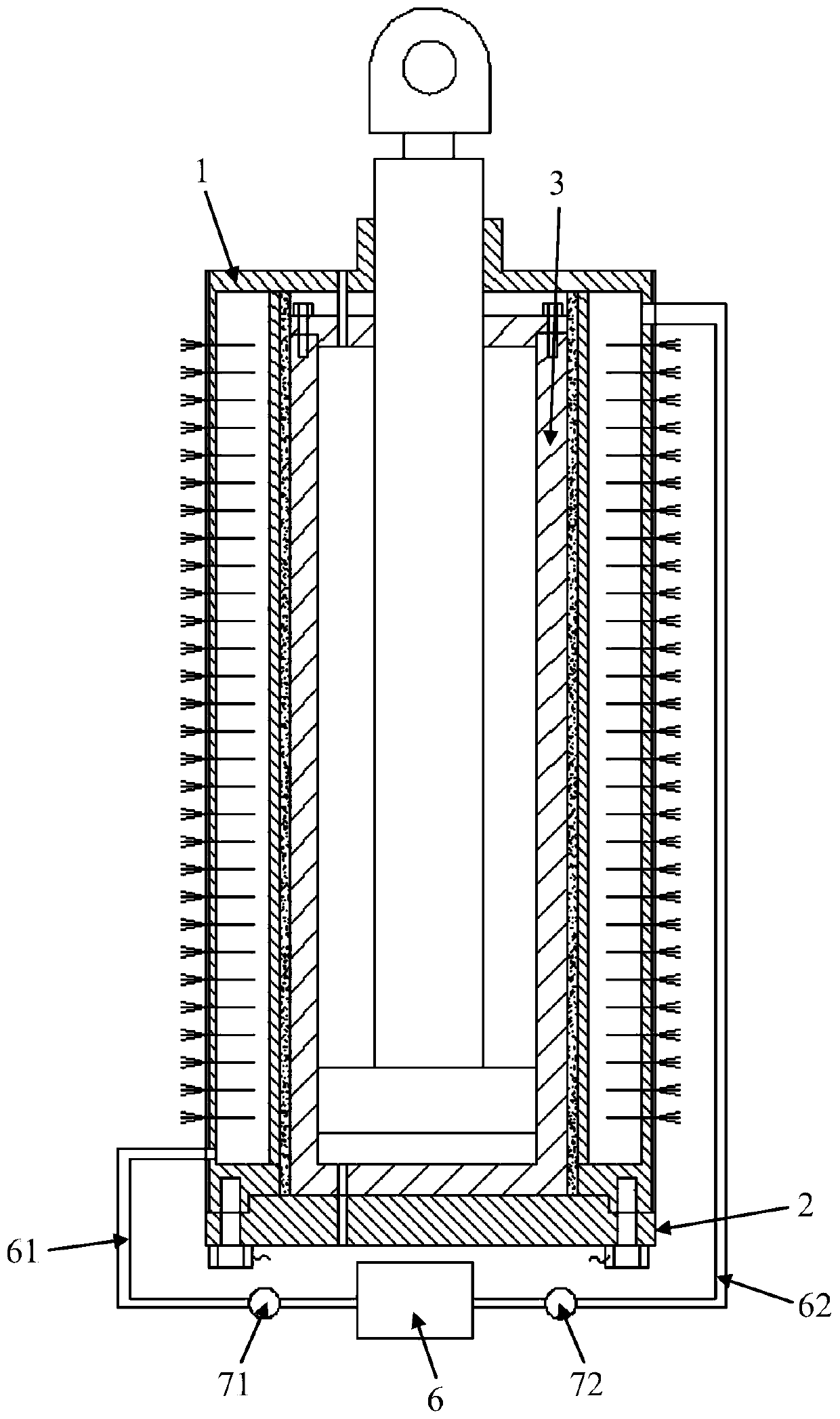

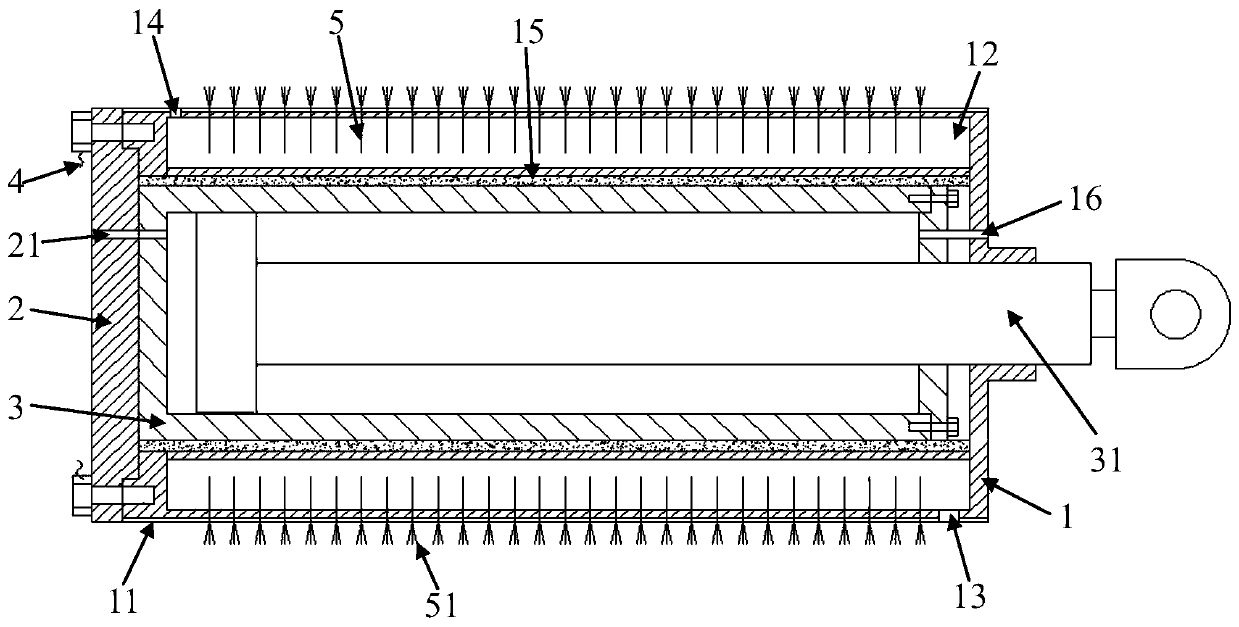

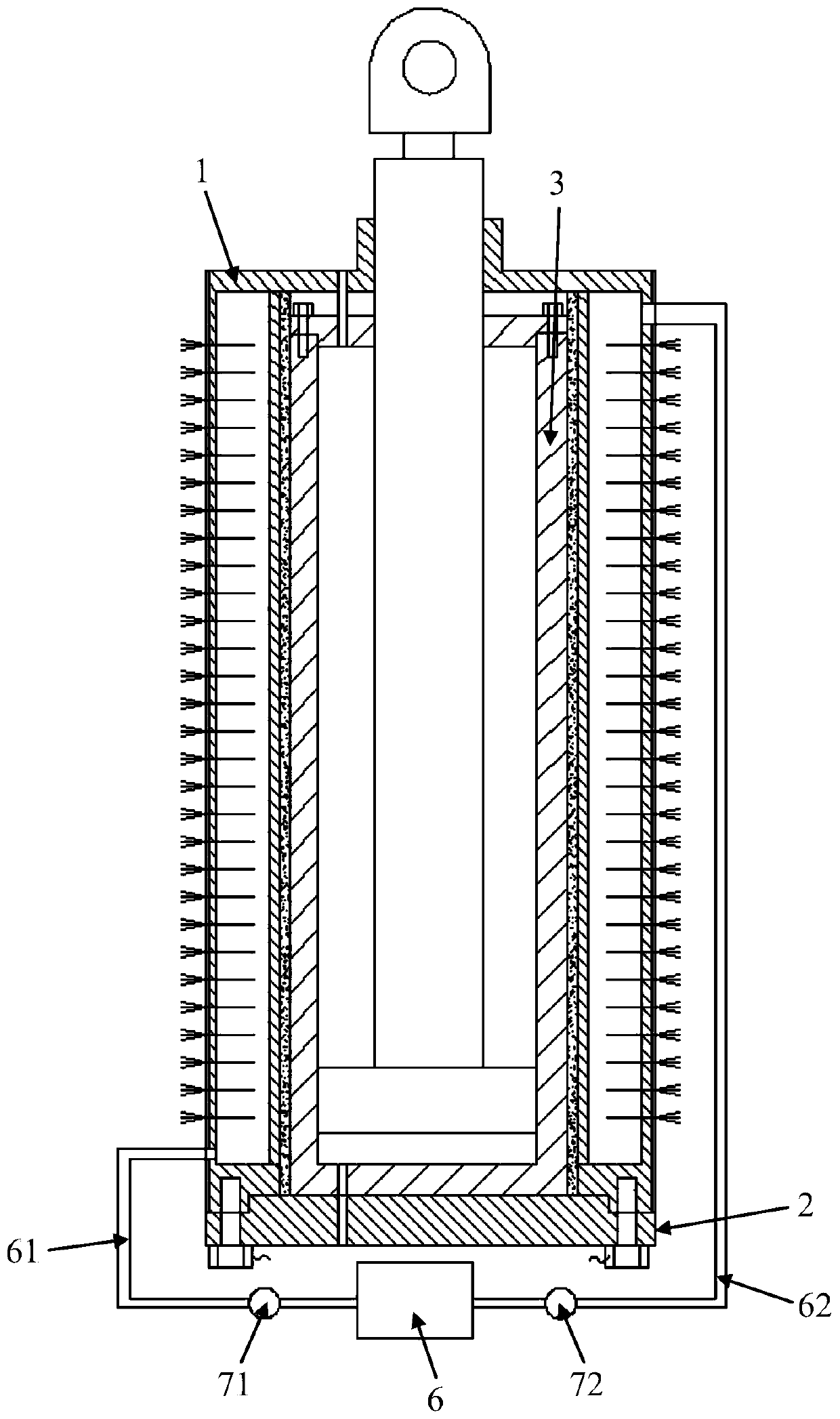

[0029] refer to figure 1 and figure 2 It can be seen that the present invention discloses a magnetic isolation and heat dissipation protection cover for a hydraulic cylinder, which includes a cylinder body 1, an end plate 2 and a cooler 6; wherein, the cylinder body 1 is covered on the hydraulic cylinder 3, and the bottom end of the cylinder body 1 can be The end plate 2 used to support the hydraulic cylinder 3 is disassembled and installed, and the top of the cylinder body 1 is formed with a mounting hole for the piston rod 31 of the hydraulic cylinder 3 to pass through. The piston rod 31 and the mounting hole are in clearance fit. A conductive fiber layer 11 is provided, a cooling chamber 12 is formed in the body of the cylinder 1, and a mixed solution that undergoes a reversible reaction is stored in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com