Novel magnetic field modulation type magnetic screw

A magnetic field modulation, magnetic screw technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electrical components, etc., can solve the problems of small output per unit permanent magnet, unsuitable for long-stroke applications, complex structure, etc. Achieve the effect of improving thrust density, simple structure and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: The stator 100 is located outside the helical magnetic ring 300 , and the rotor 200 is inside the helical magnetic ring 300 .

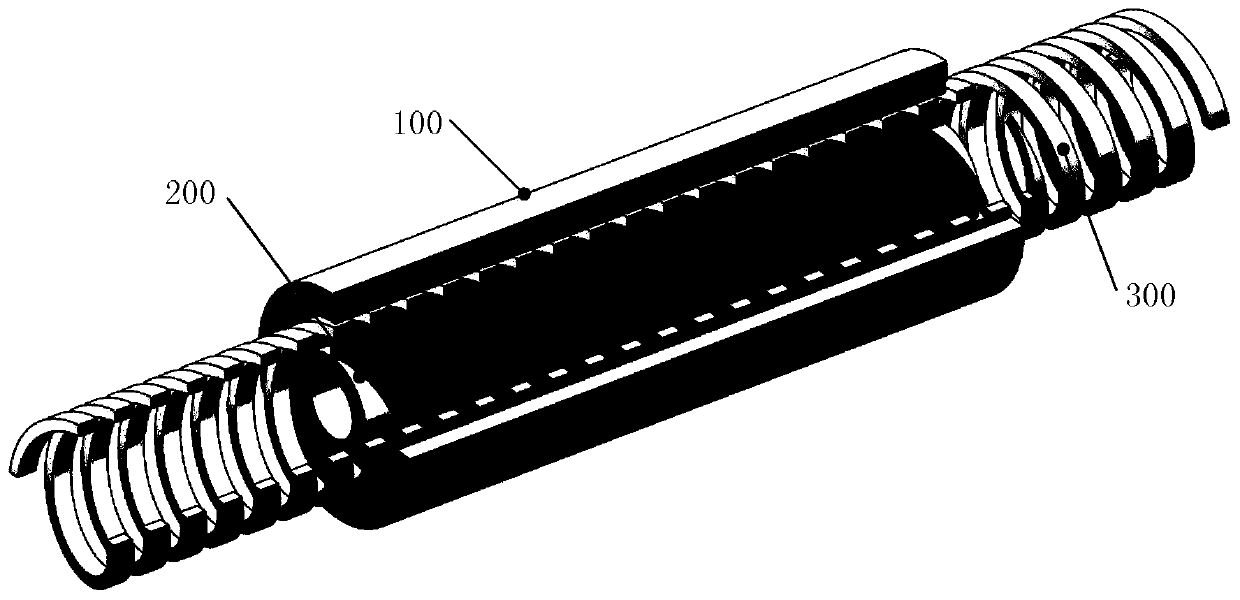

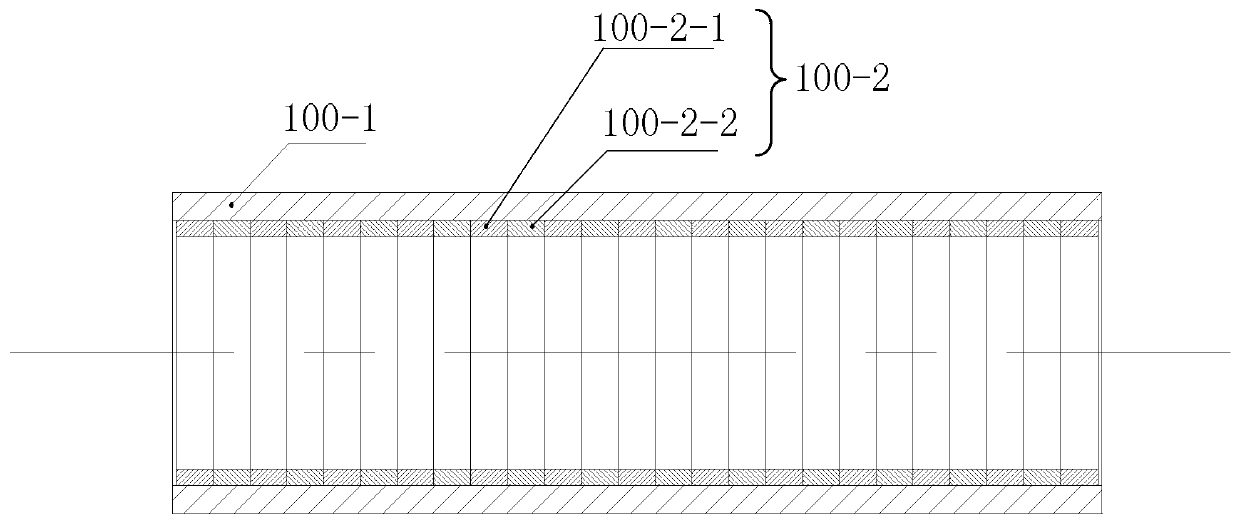

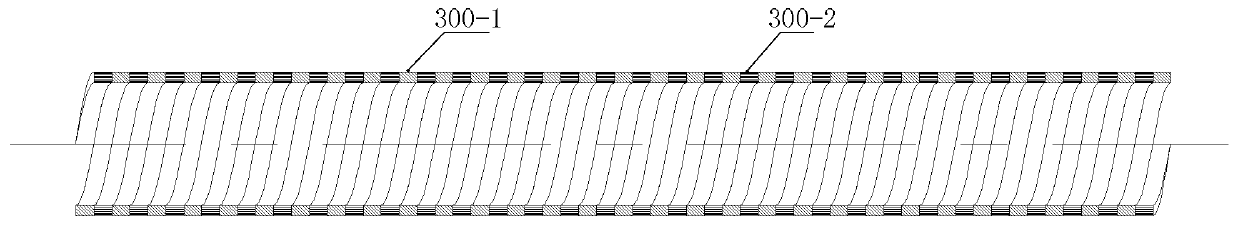

[0050] see figure 1 Describe the specific embodiment 1. The new magnetic field modulation type magnetic lead screw described in this embodiment 1 includes a stator 100, a rotor 200 and a helical magnetic ring 300, and the three are coaxially arranged;

[0051] Both the stator 100 and the rotor 200 are cylindrical structures, and they are arranged opposite to each other;

[0052] The helical magnetic ring 300 is located between the stator 100 and the rotor 200, and there is an air gap between the helical magnetic ring 300 and the stator 100 and the rotor 200;

[0053] The stator 100 is located outside the helical magnetic ring 300, and the rotor 200 is inside the helical magnetic ring 300;

[0054] After the rotor 200 is rotated by the external driving force, the helical magnetic field generated by the permanent magnet on the rot...

Embodiment 2

[0075] Embodiment 2: The stator 100 is located inside the helical magnetic ring 300 , and the rotor 200 is outside the helical magnetic ring 300 .

[0076] see Figure 7 Describe specific embodiment 2, the novel magnetic field modulation type magnetic lead screw described in the present embodiment 2, comprises stator 100, rotor 200 and helical magnetic ring 300, and the three are coaxially arranged;

[0077] Both the stator 100 and the rotor 200 are cylindrical structures, and they are arranged opposite to each other;

[0078] The helical magnetic ring 300 is located between the stator 100 and the rotor 200, and there is an air gap between the helical magnetic ring 300 and the stator 100 and the rotor 200;

[0079] The stator 100 is located inside the helical magnetic ring 300, and the rotor 200 is outside the helical magnetic ring 300;

[0080] After the rotor 200 is rotated by the external driving force, the helical magnetic field generated by the permanent magnet on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com