Wet flue gas desulfurization tower

A technology of wet flue gas desulfurization and flue gas inlet, which is applied in the field of desulfurization towers, can solve the problems of lower flue gas lift height, gypsum rain, and low exhaust temperature, so as to reduce water consumption, reduce construction cost, and increase heat transfer area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

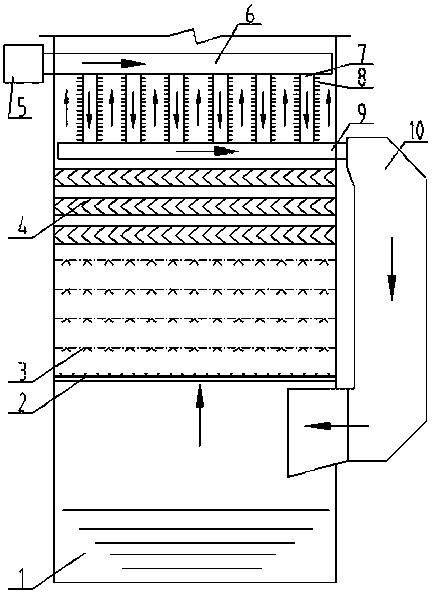

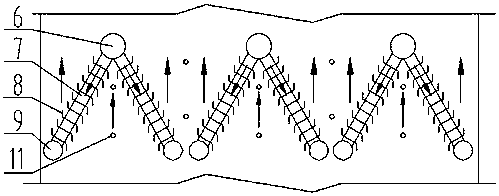

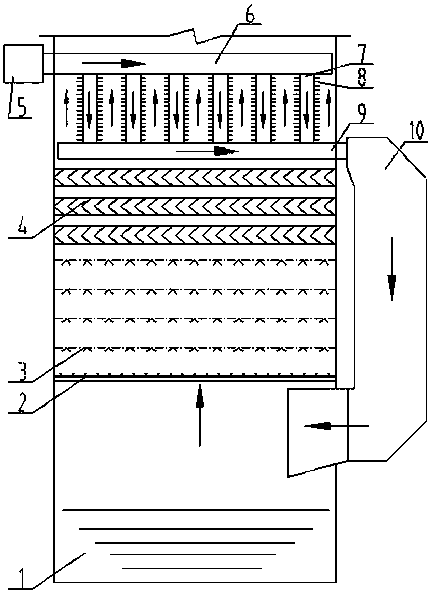

[0021] refer to figure 1 , this embodiment includes a tower body, and the tower body is sequentially provided with a desulfurization slurry pool 1, a tray 2, a slurry spray layer 3, a common demister 4, and a heating demister from bottom to top. The heating demister includes flue gas Inlet header 5, inlet main pipe 6, heat dissipation pipe 7, heat sink 8, outlet main pipe 9, connecting flue 10, demister flushing pipe 11, flue gas inlet header 5 leads to multiple inlet main pipes 6, smoke The gas inlet header 5 communicates with the inlet main pipe 6, refer to figure 2 , two groups of heat dissipation pipes 7 are led obliquely below each inlet main pipe 6 to form a triangular arrangement of sub-units. The inlet main pipe 6 communicates with the heat dissipation pipe 7; the end of the heat dissipation pipe 7 is connected with the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com