3D-printing aerogel down fabric and production process thereof

A technology of 3D printing and down fabrics, which is applied in the field of fabrics, can solve the problems of high risk, ash phenomenon, environmental pollution, etc., and achieve the effect of good lightness and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

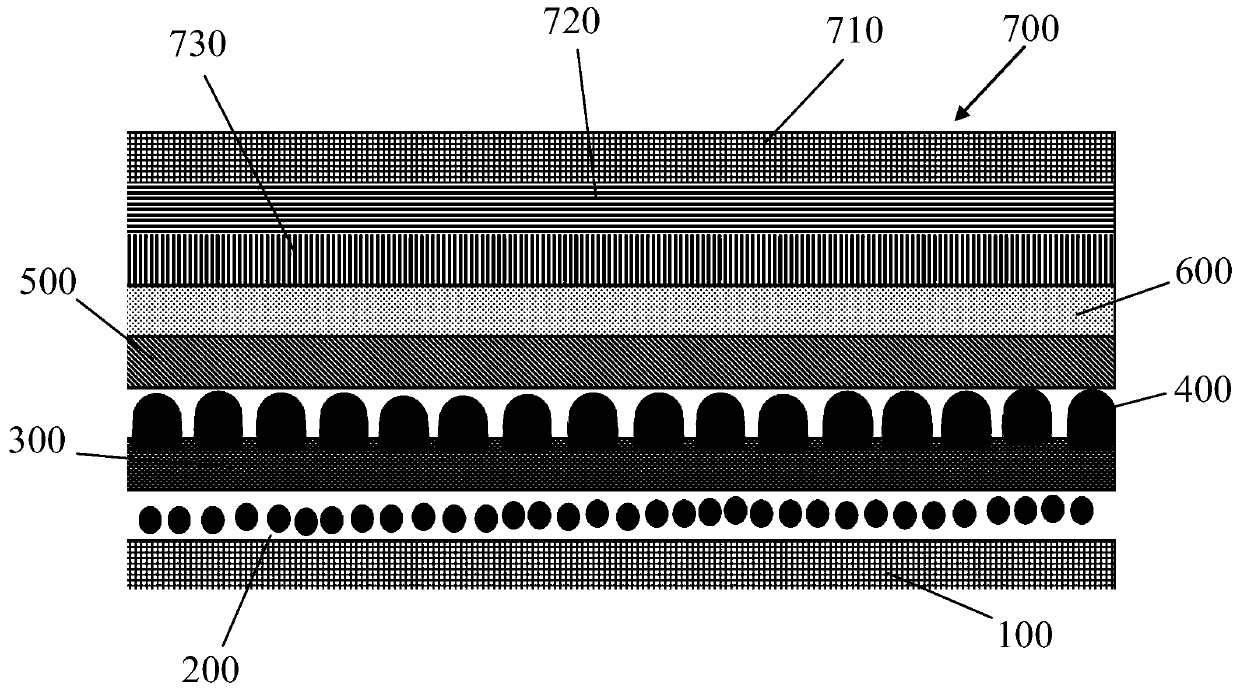

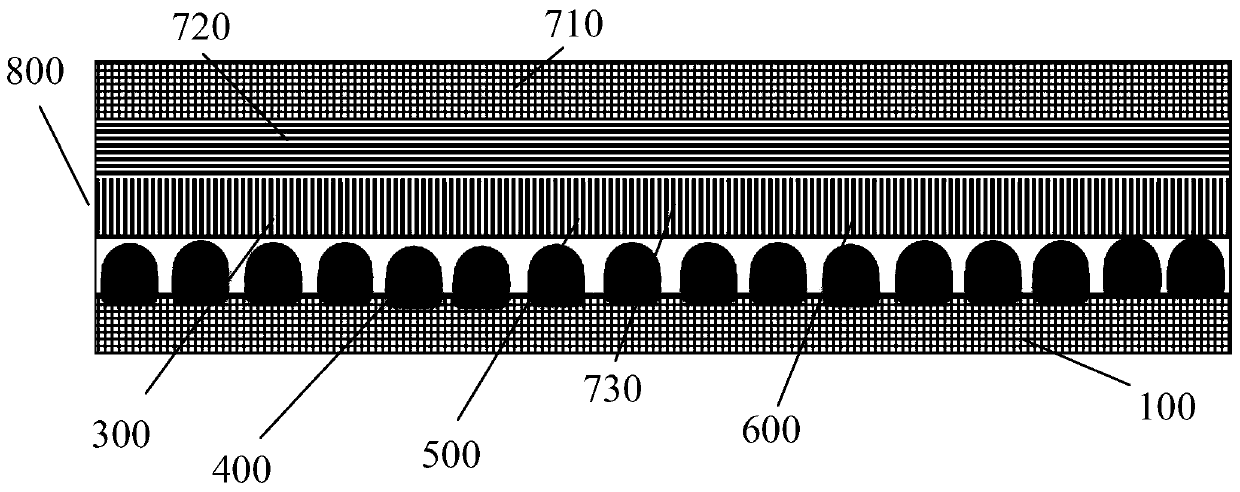

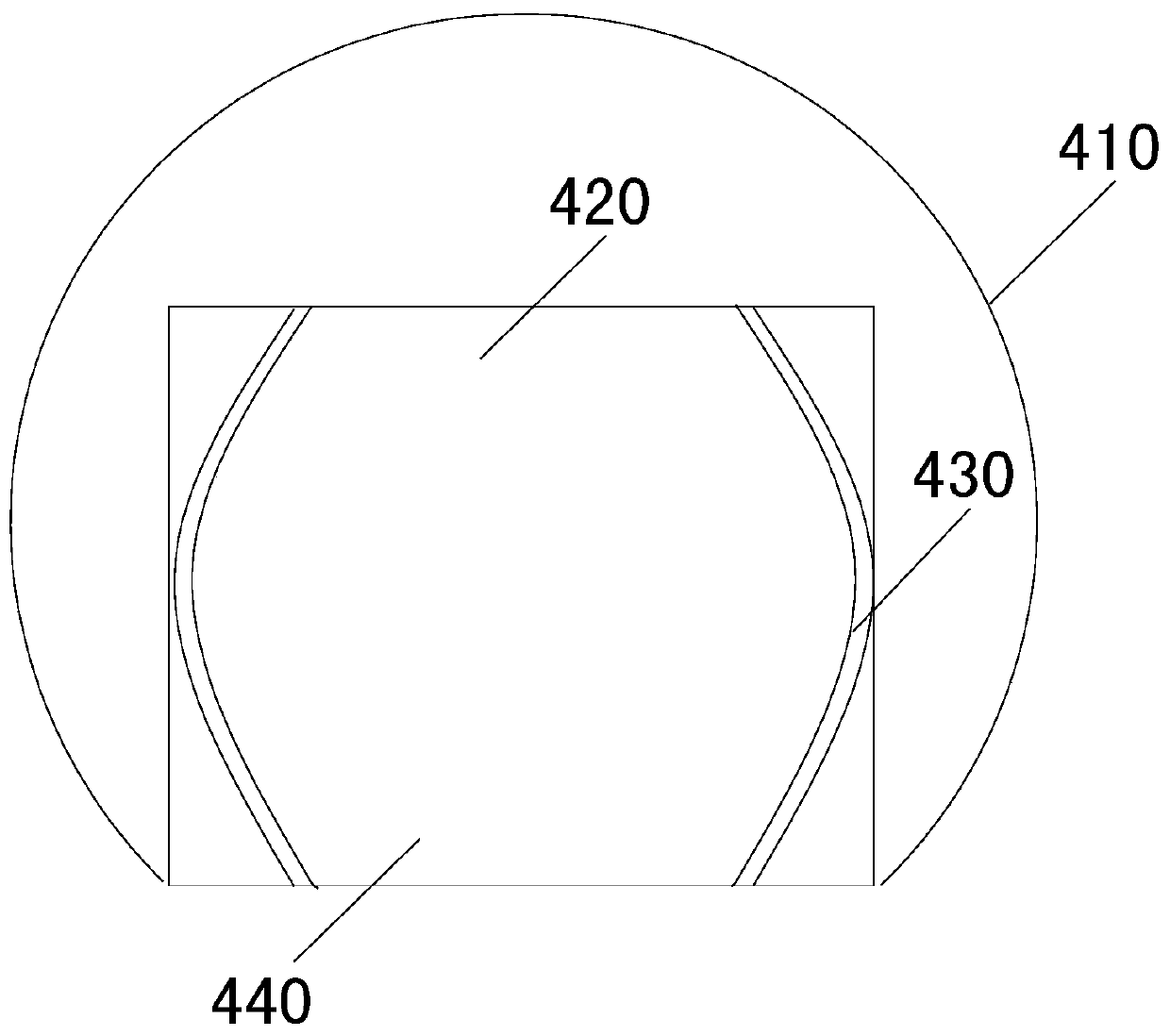

[0039] figure 1 It is a disassembled structure diagram of the present invention. figure 2 It is the structure diagram of the finished product of the present invention. image 3 It is the structural diagram of the airgel columnar foam.

[0040] A 3D printing airgel down fabric includes: bottom fabric 100, adhesive layer 200, windproof and breathable layer 300, airgel columnar foam 400, elastic lock down layer 500, down layer 600 and surface fabric 700, bottom fabric 100 is bonded to the bottom of the windproof and breathable layer 300 through the bonding layer 200, the top of the windproof and breathable layer 300 is connected to the bottom of the airgel columnar foam 400, the top of the airgel columnar foam 400 is connected to the elastic lock fleece layer 500, and the elastic A down layer 600 is provided on the top of the lock down layer 500, and the bottom of the surface fabric 700 is embedded with the windproof and breathable layer 300, the airgel columnar foam 400, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com