Patents

Literature

39results about How to "Good thinness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

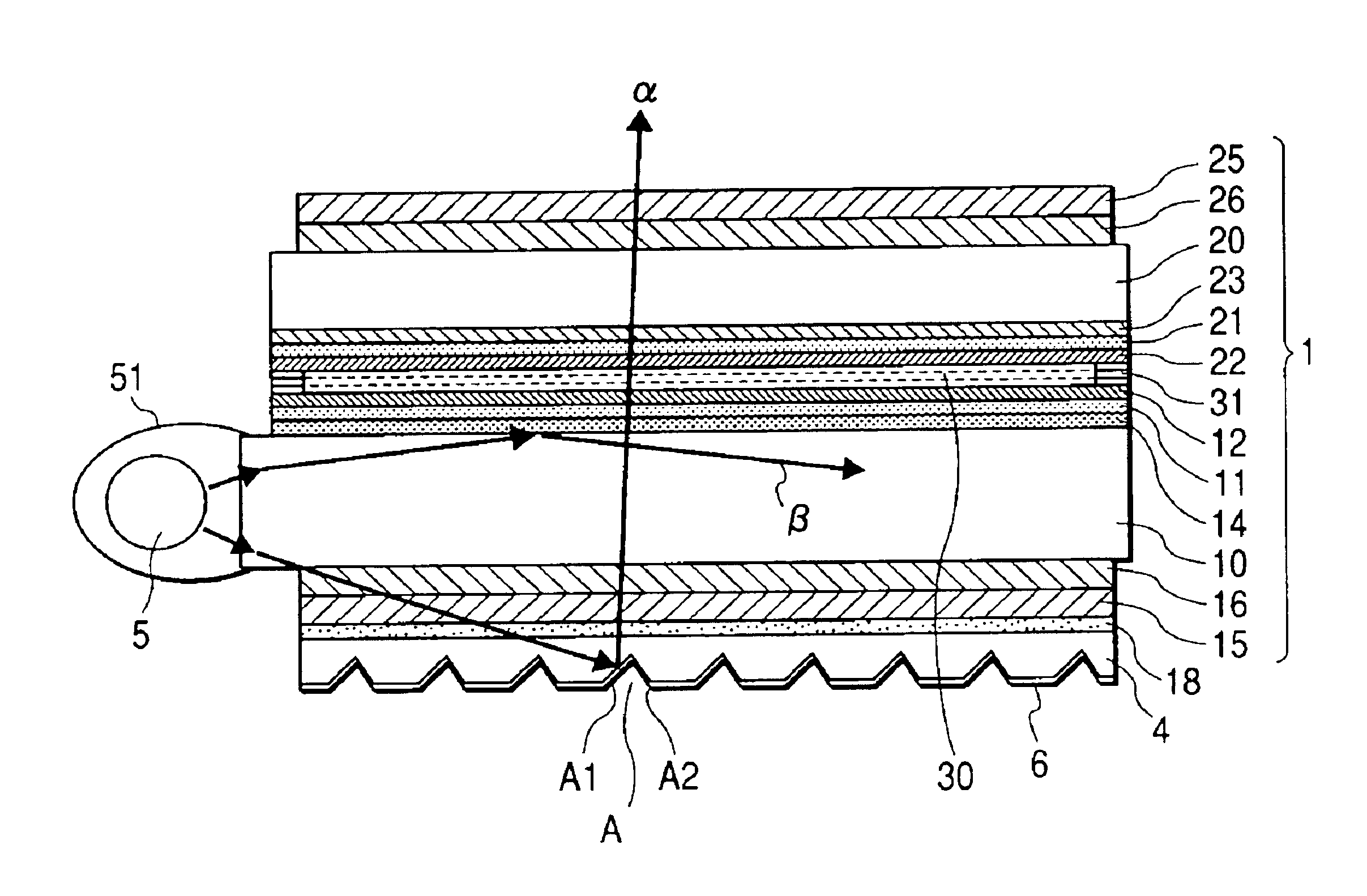

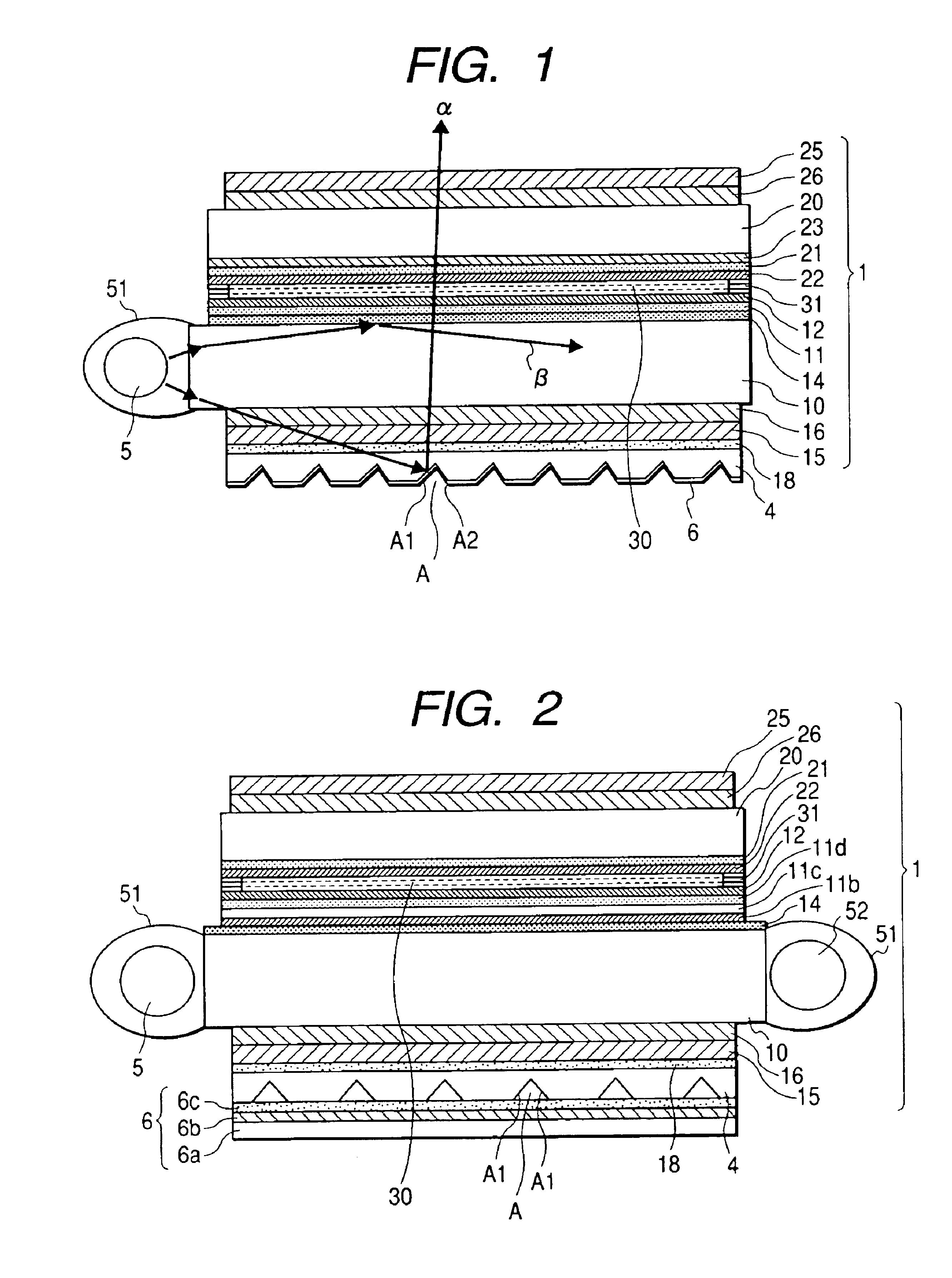

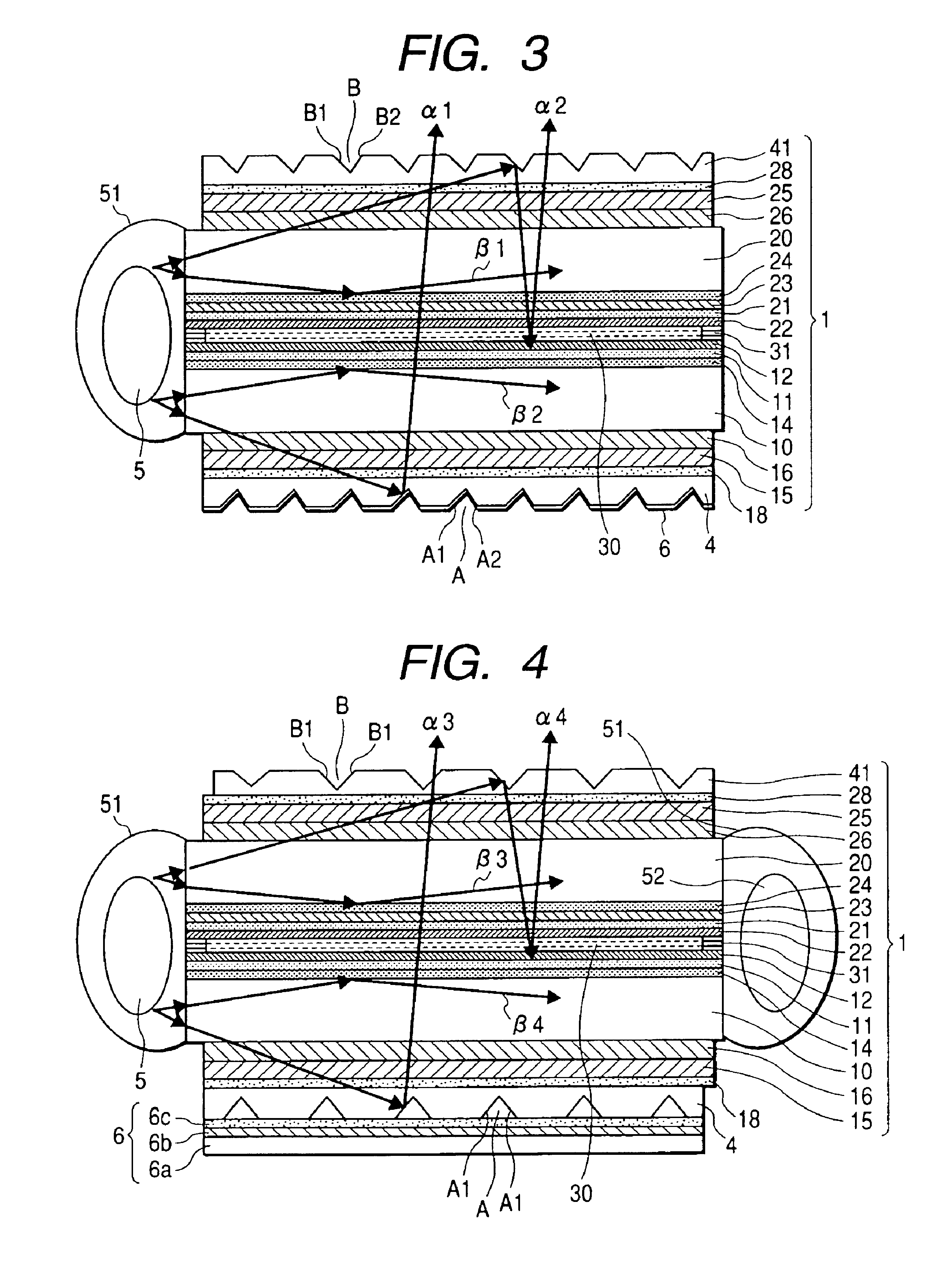

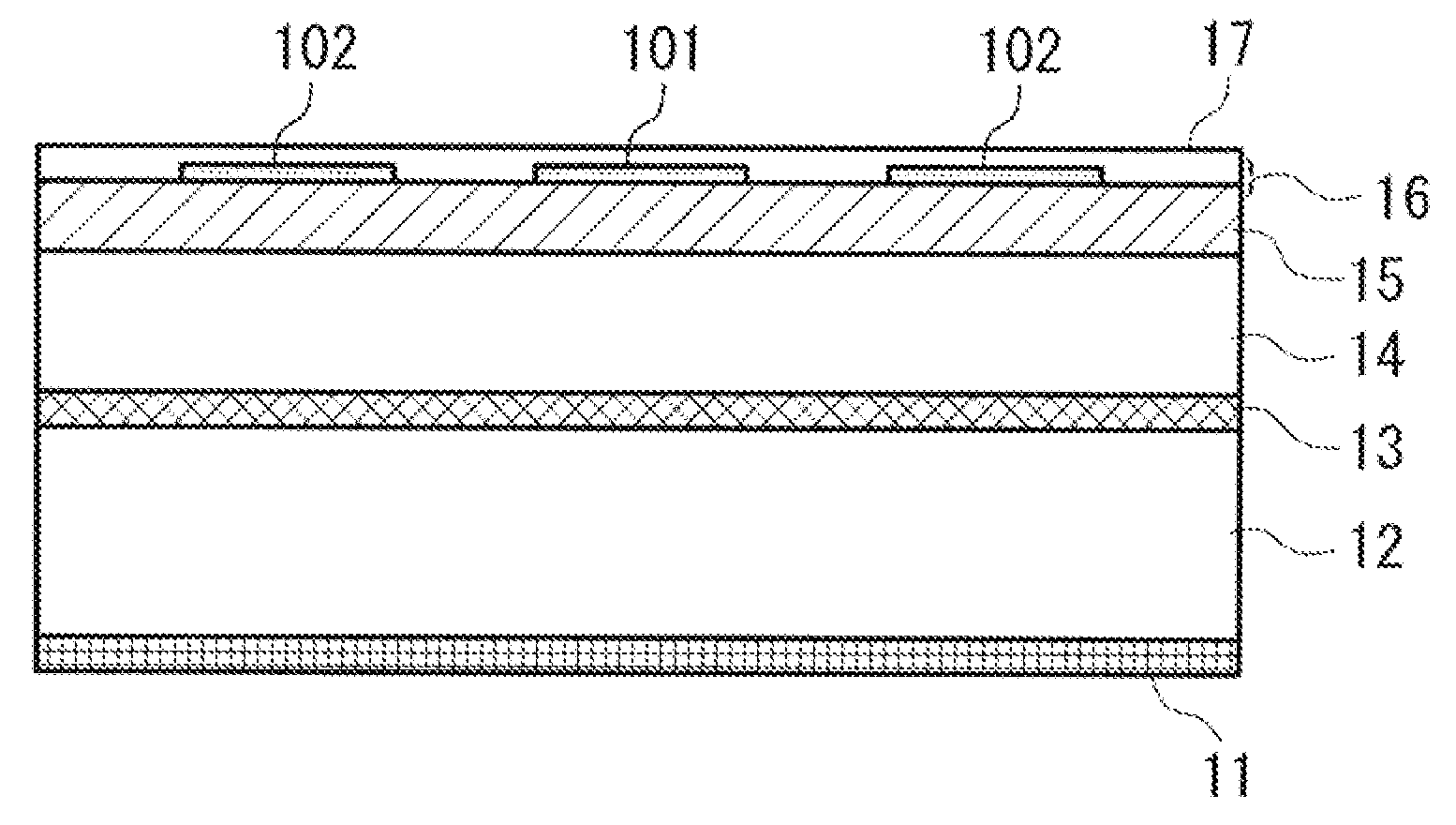

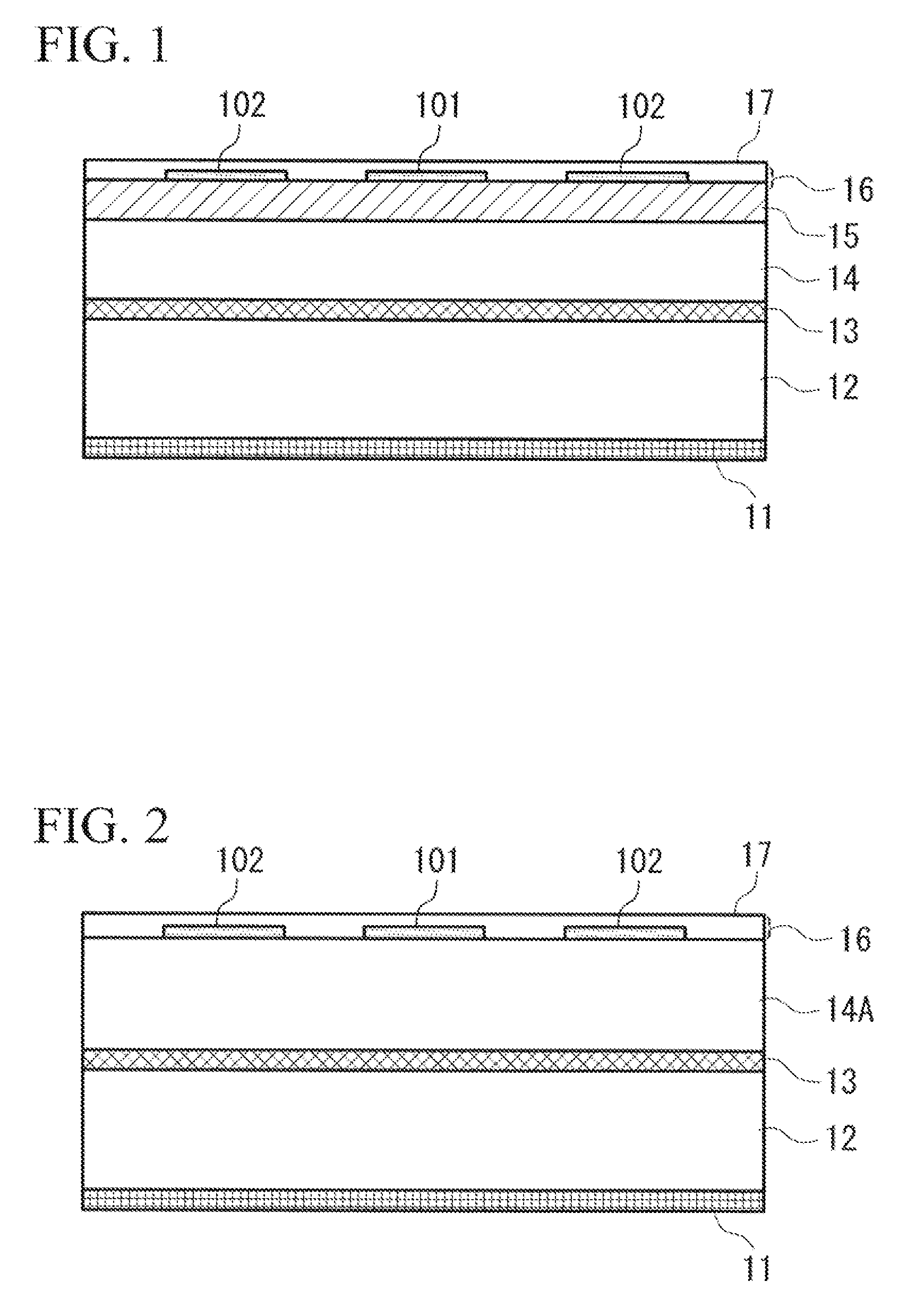

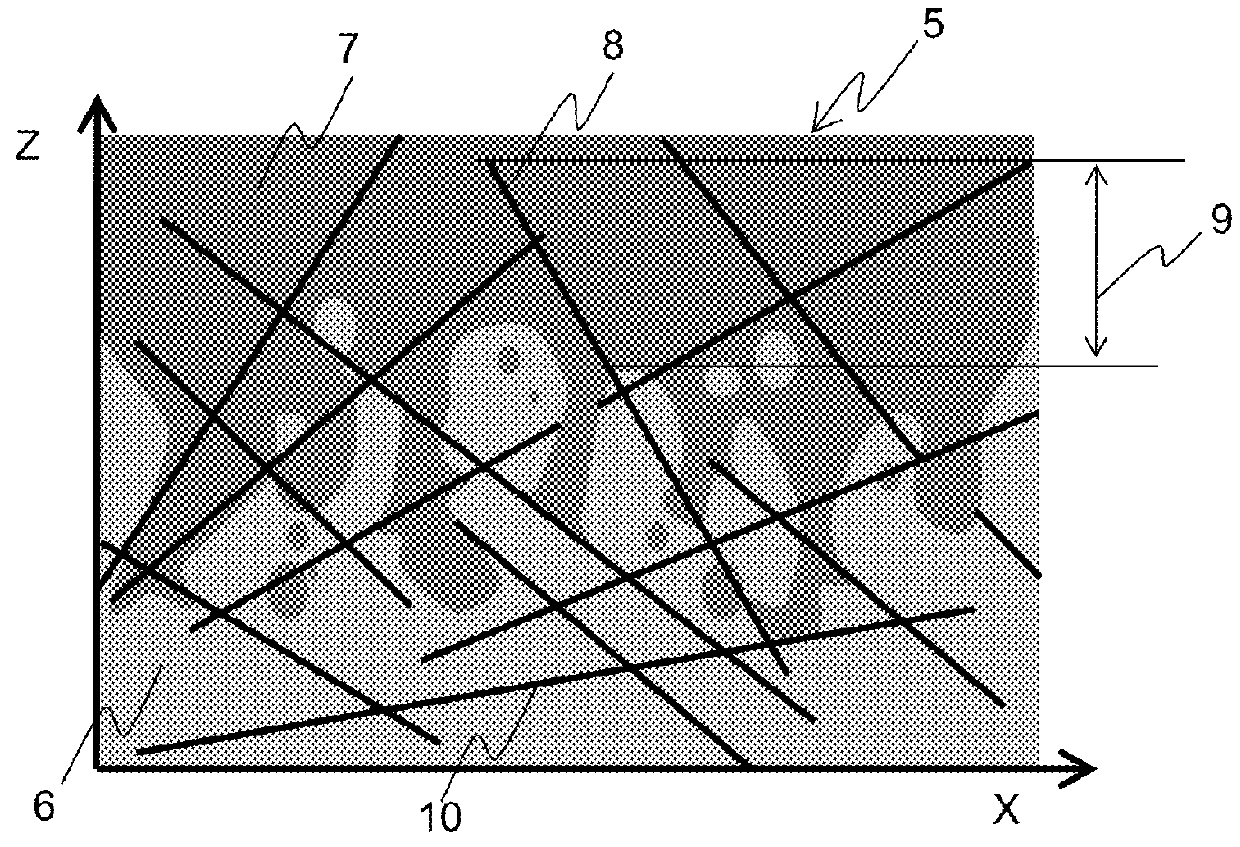

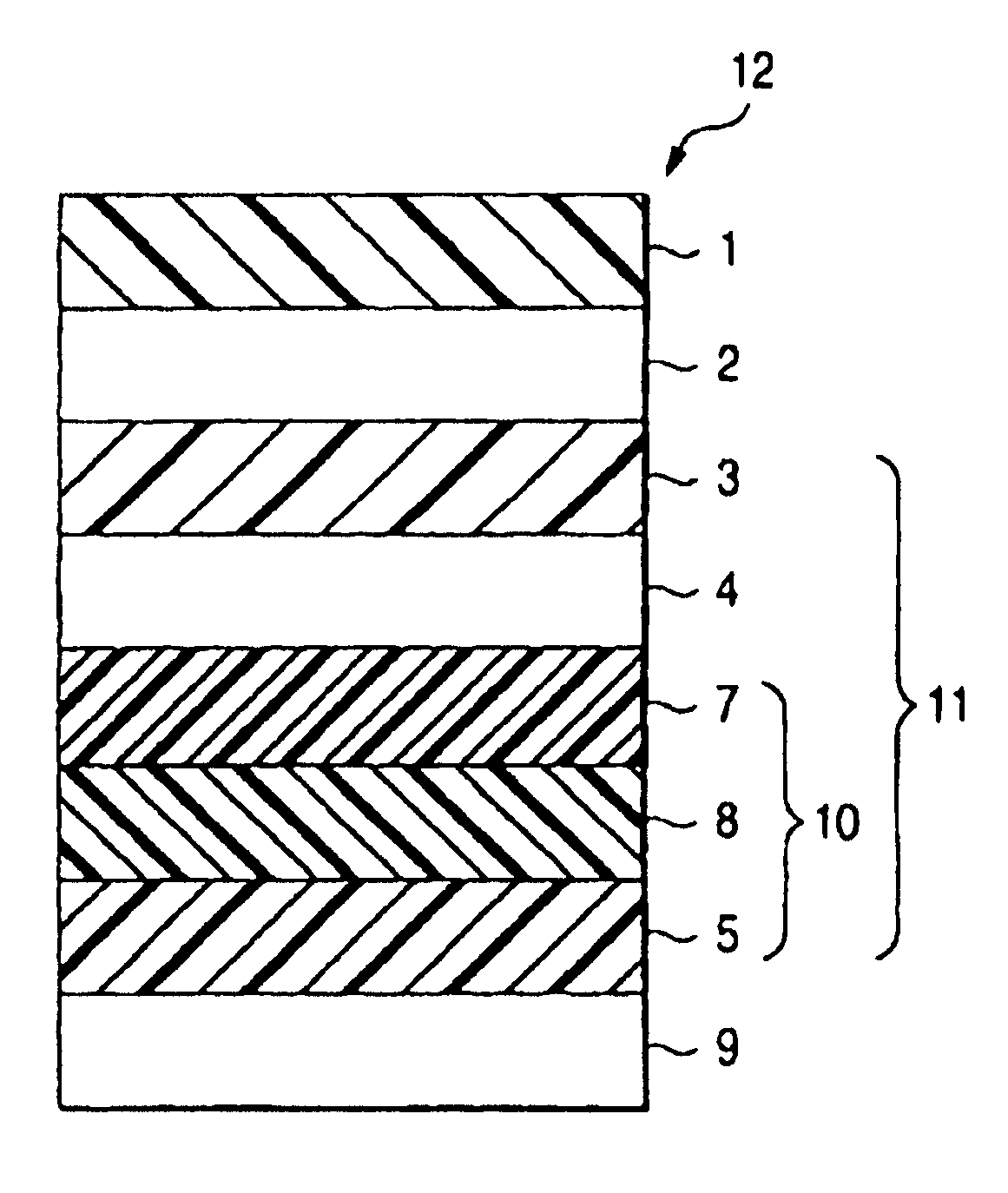

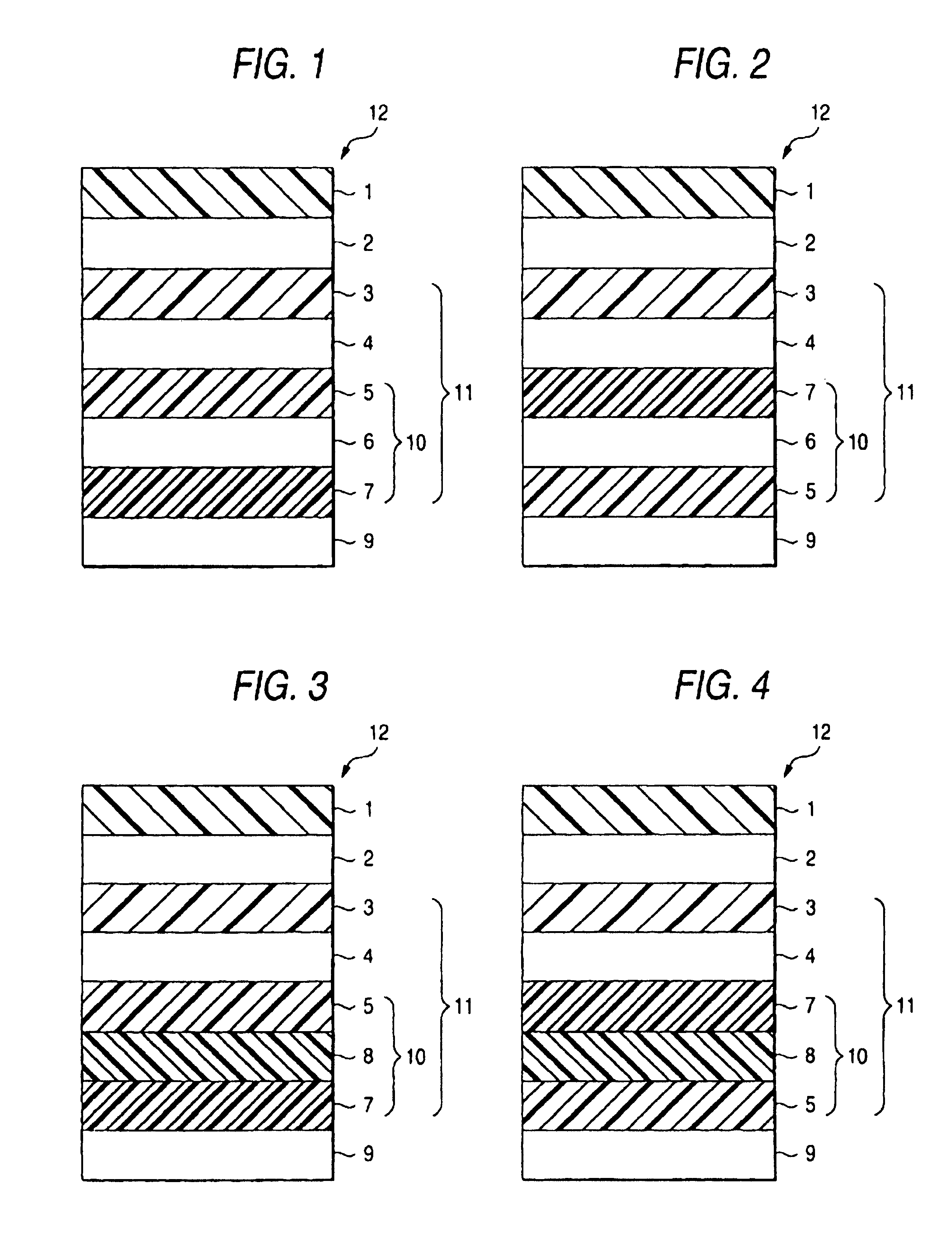

Liquid-crystal display device

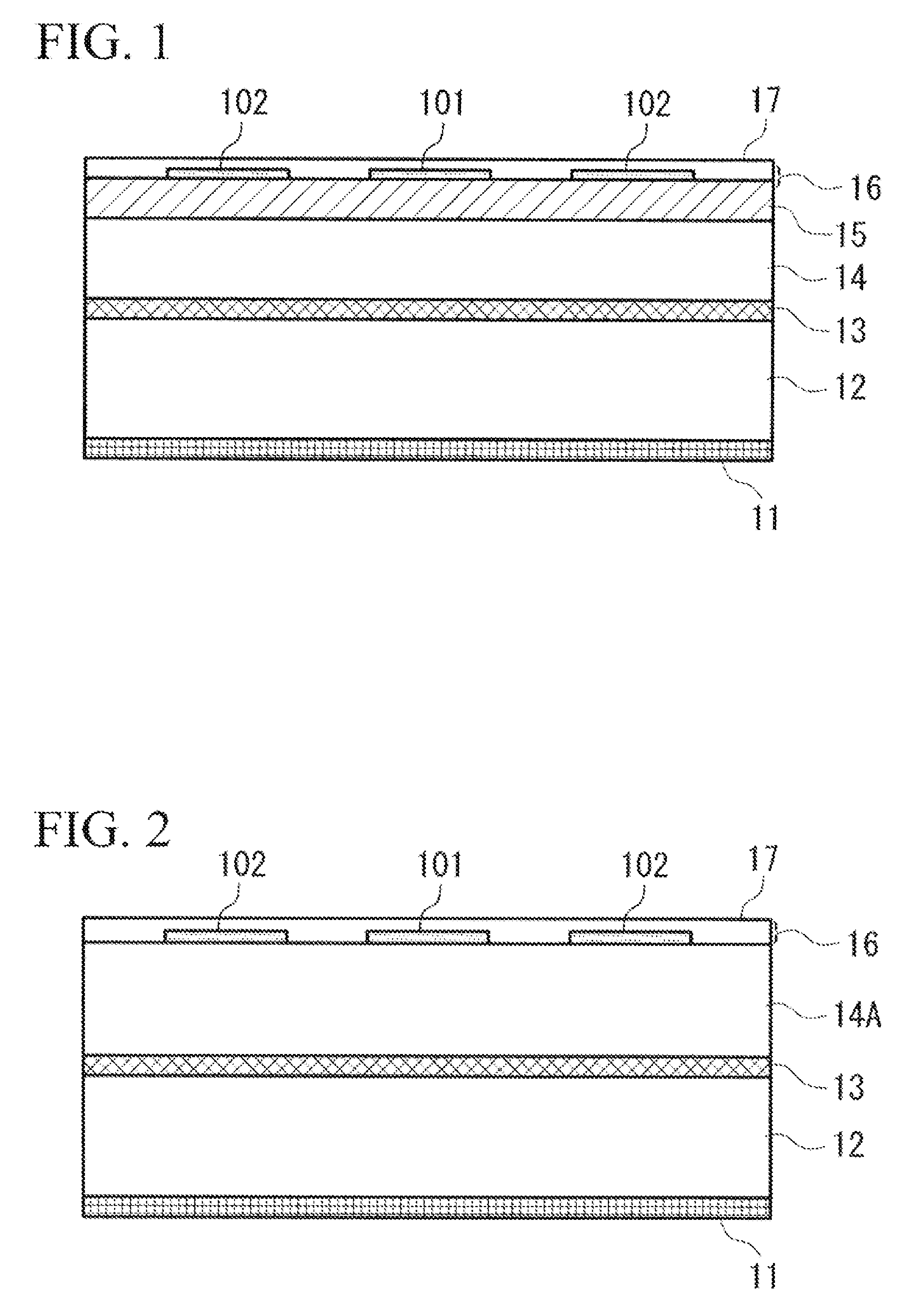

InactiveUS7030945B2Excellent in luminanceImprove uniformityNon-linear opticsControl layerLiquid-crystal display

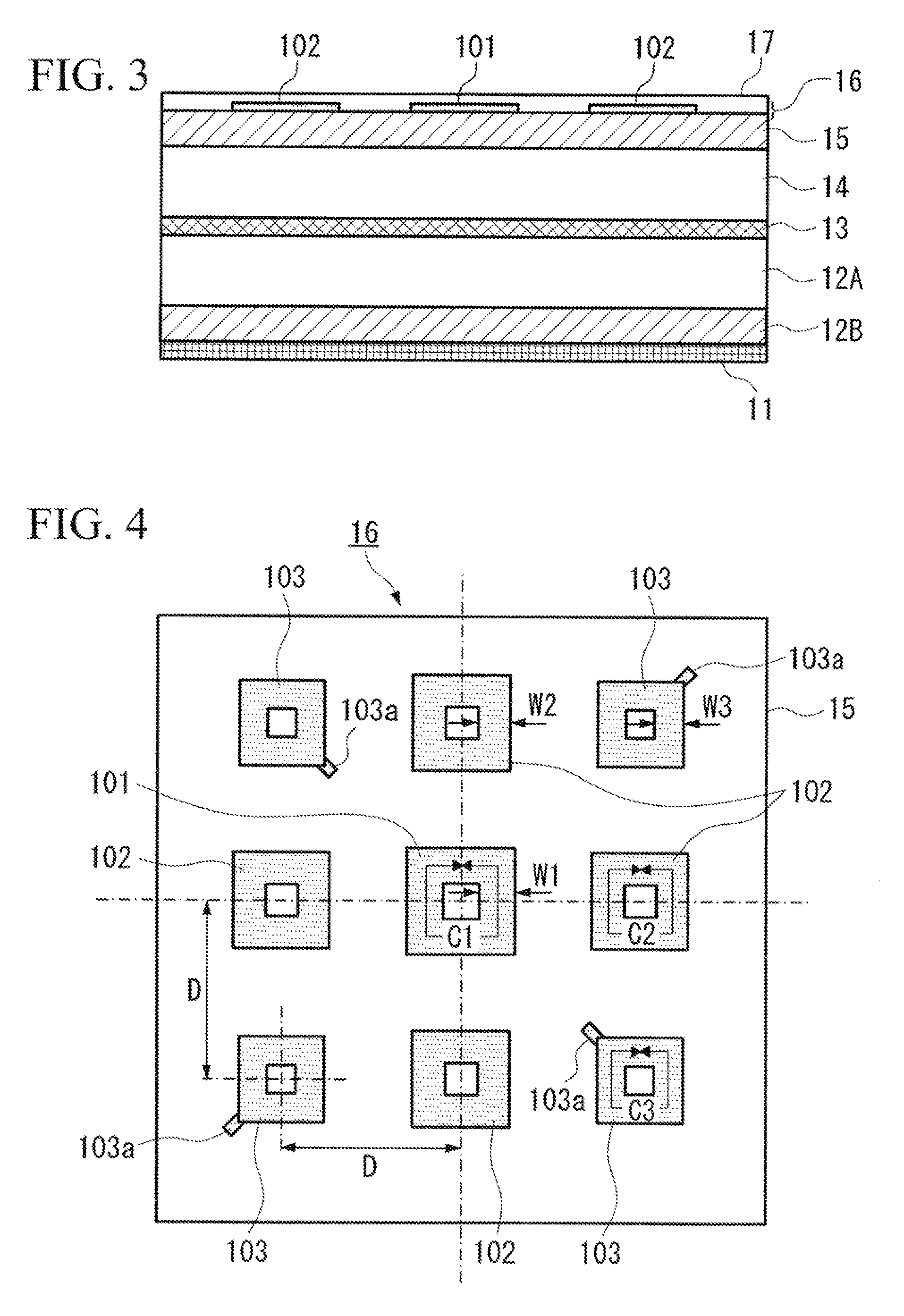

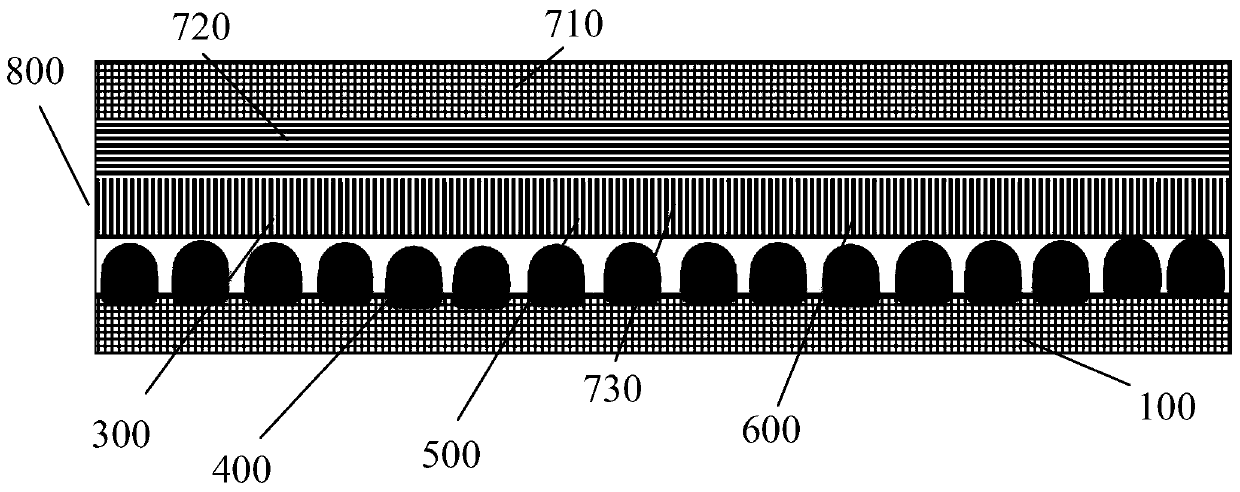

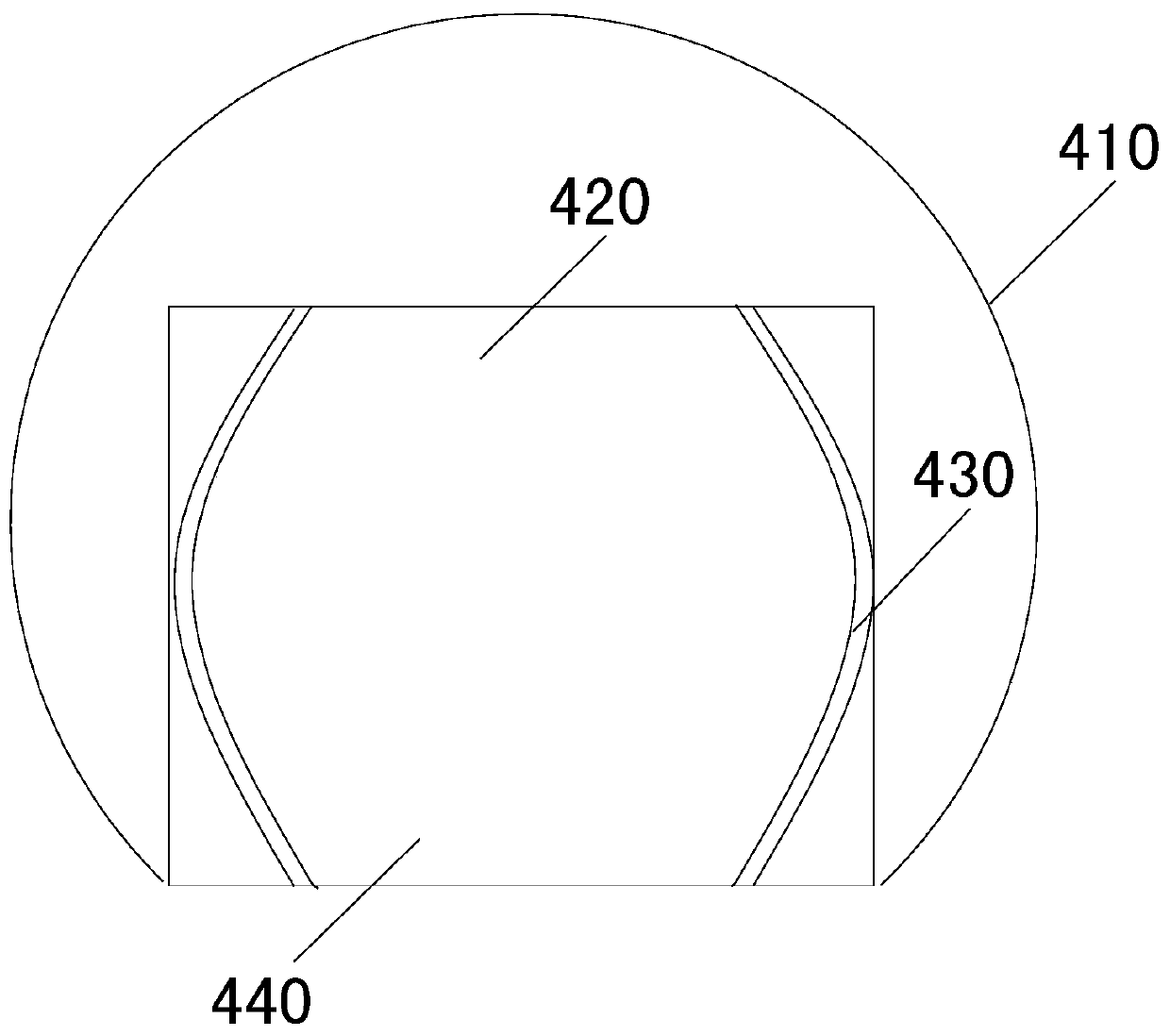

In a liquid-crystal display device, an optical path control layer is provided at least on an outer side of the back side substrate, and has a plurality of optical path changing slopes inclined at an inclination angle of from 35 to 48 degrees with respect to a reference plane of the back side substrate. The optical path control layer has a refractive index higher than that of a low-refractive-index transparent layer provided in the back side substrate. Another low-refractive-index transparent layer lower in refractive index than the transparent substrate may be provided in a visual side substrate. Light sources may be disposed on at least two side surfaces of the liquid-crystal display panel. Light sources may be disposed on side surfaces of the back side substrate and the visual side substrate and at least on side surfaces of the liquid-crystal display panel which are different from each other. Another optical path control layer may be provided also on an outer side of the visual side substrate.

Owner:NITTO DENKO CORP

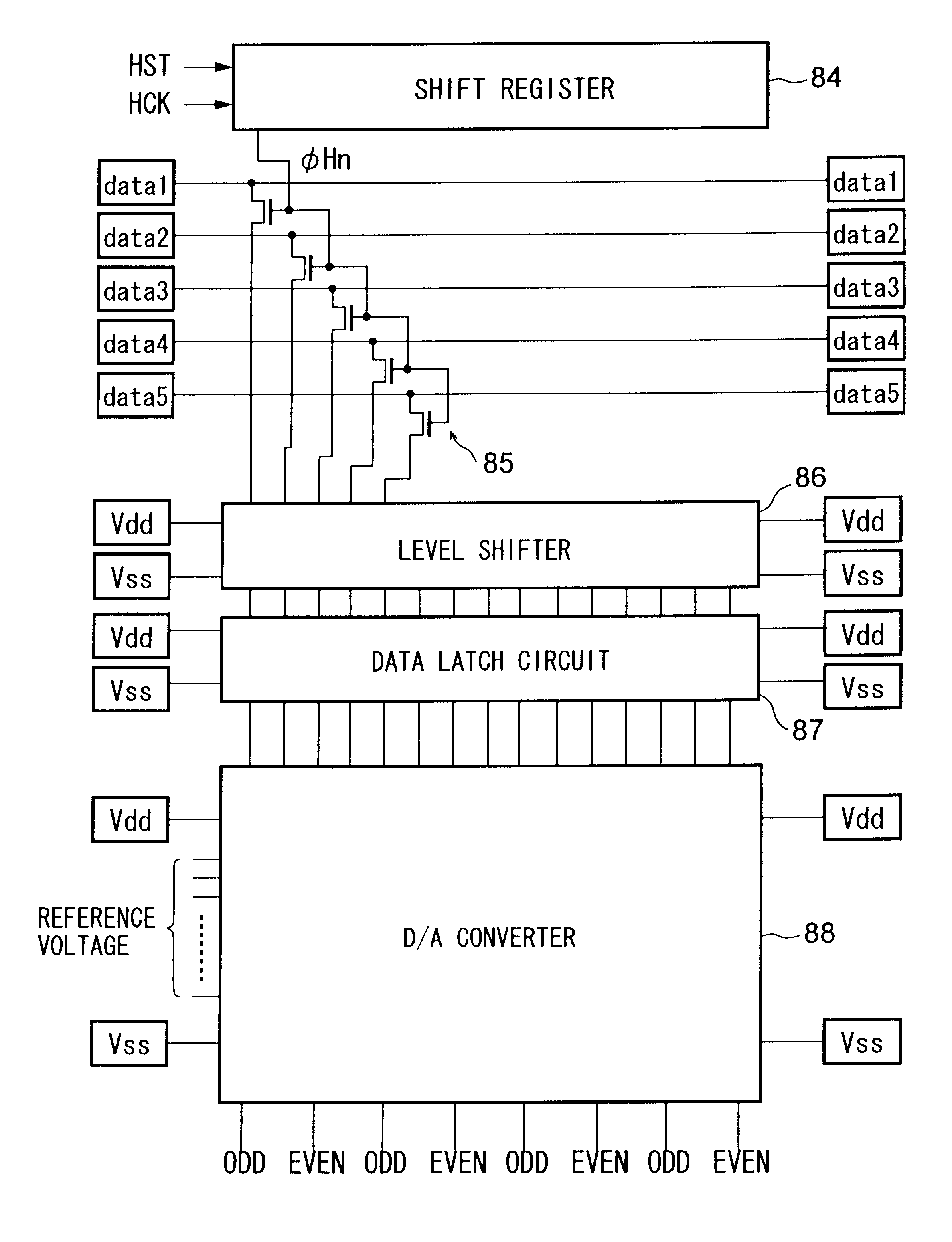

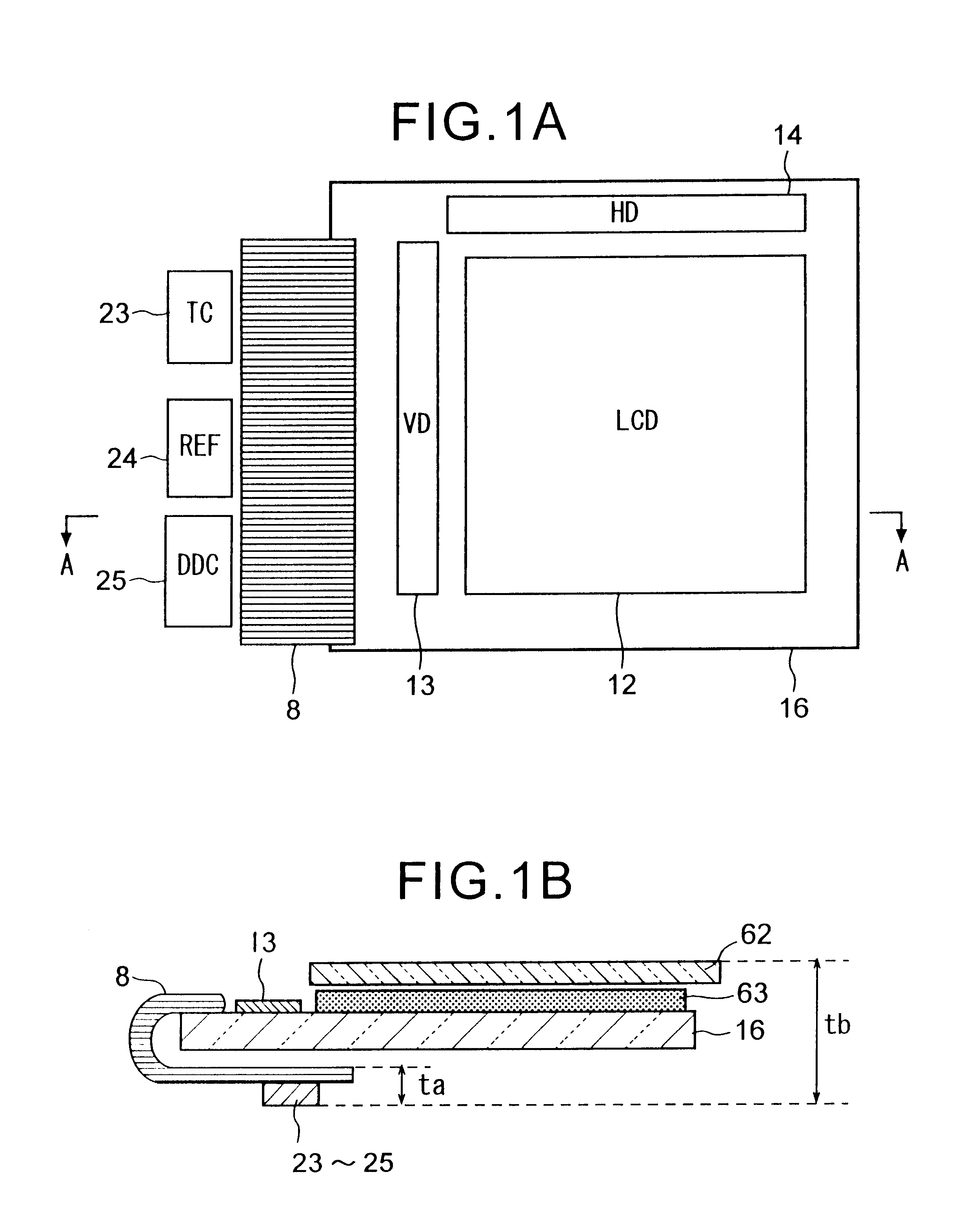

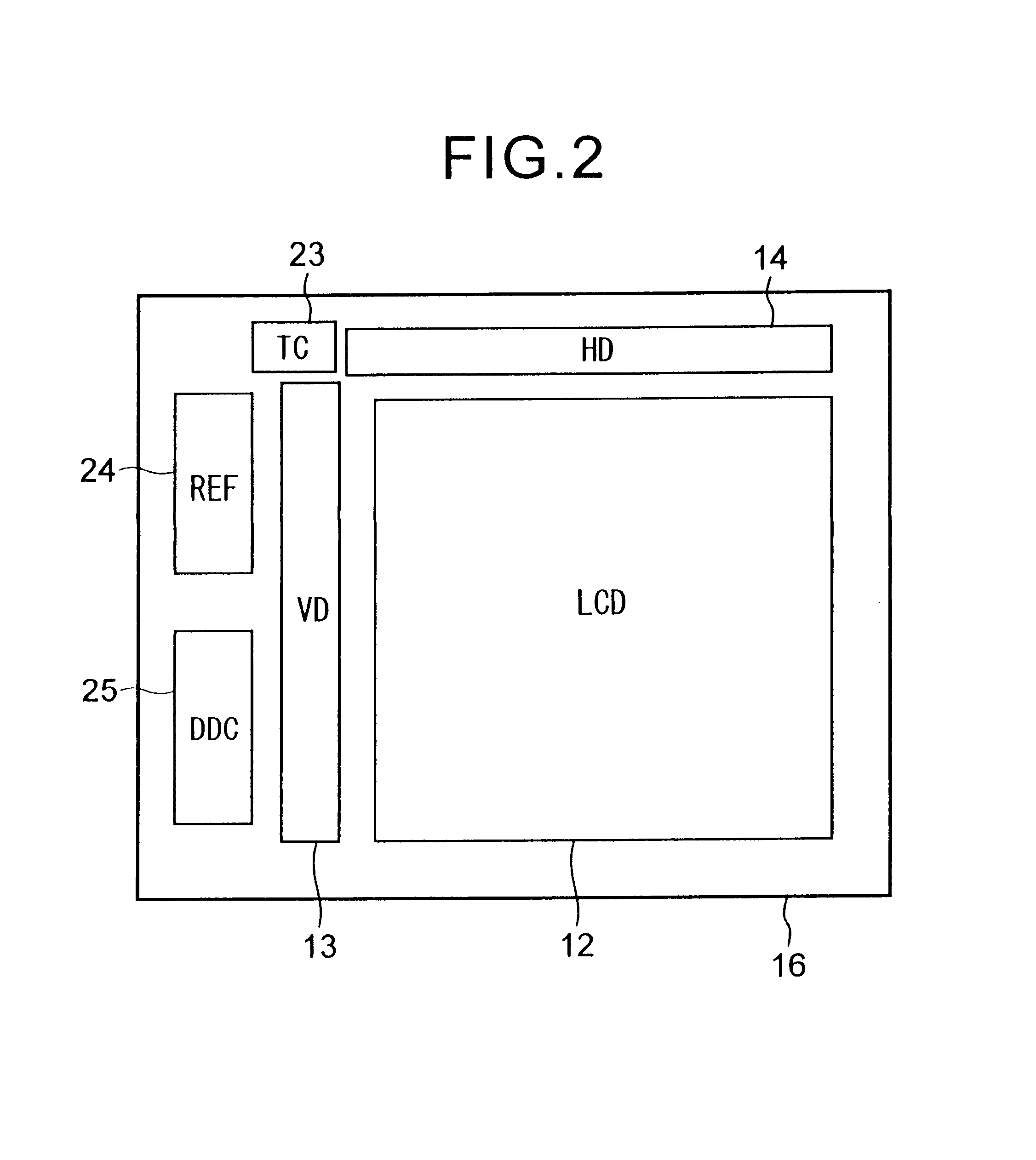

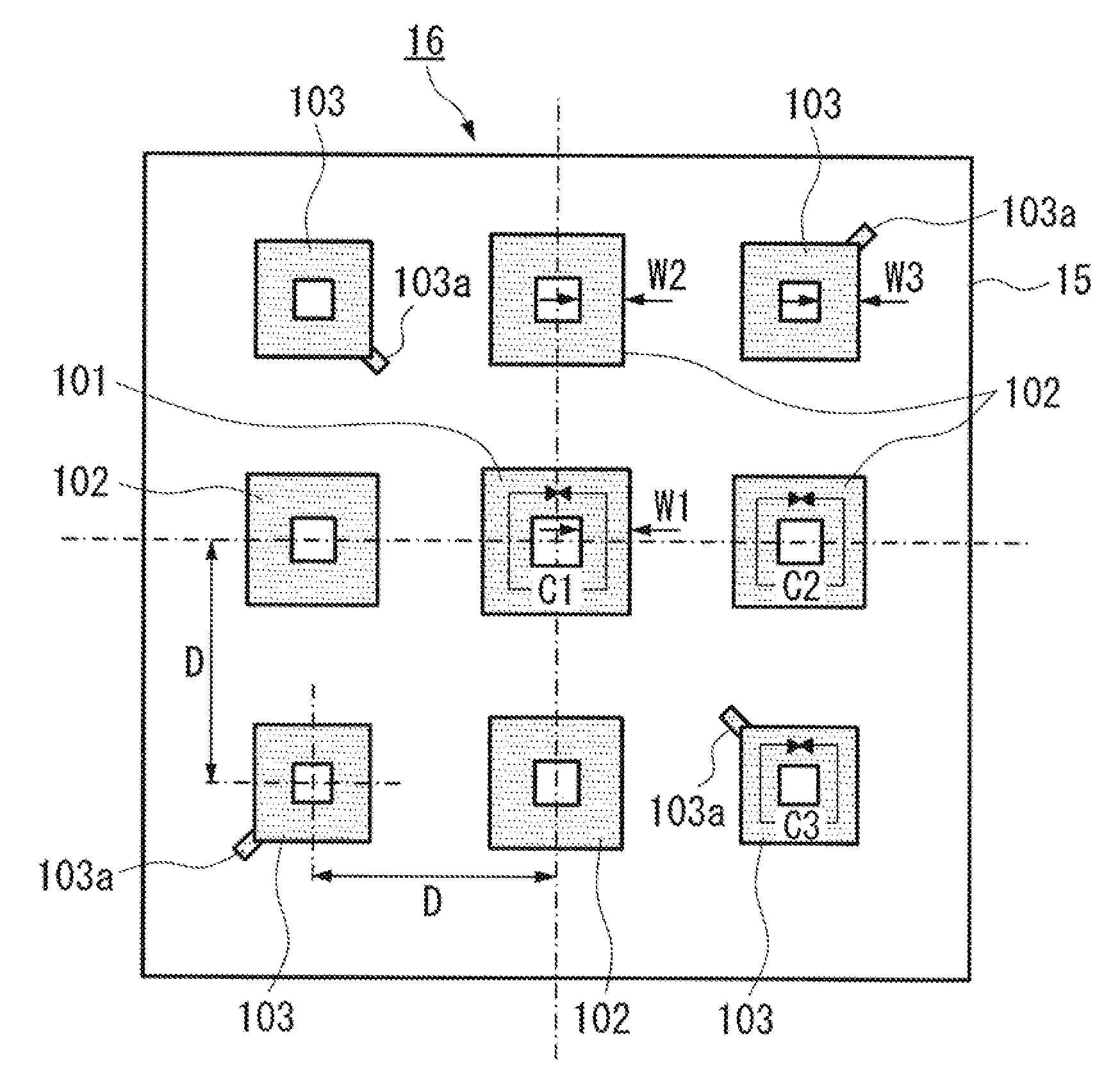

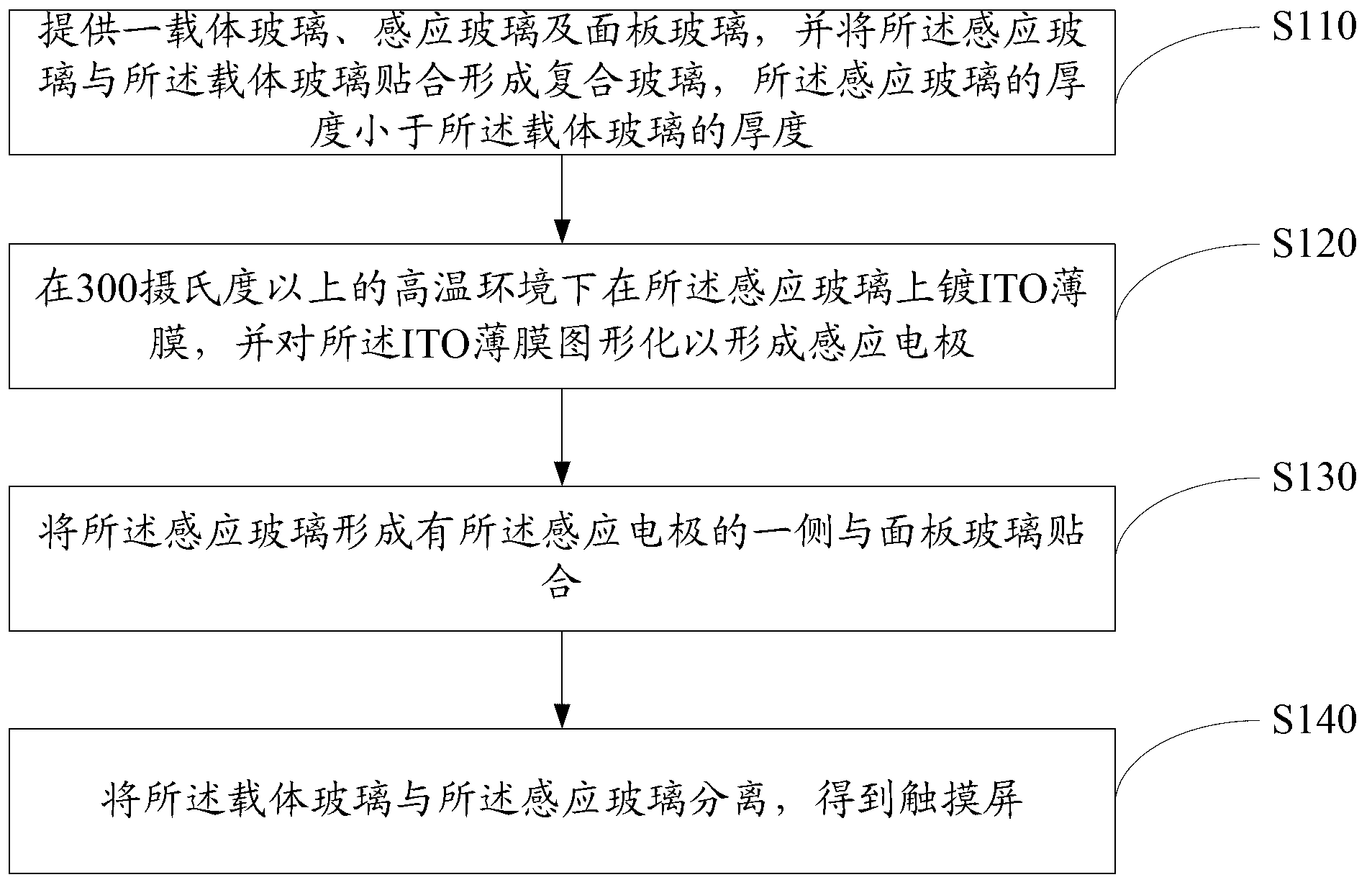

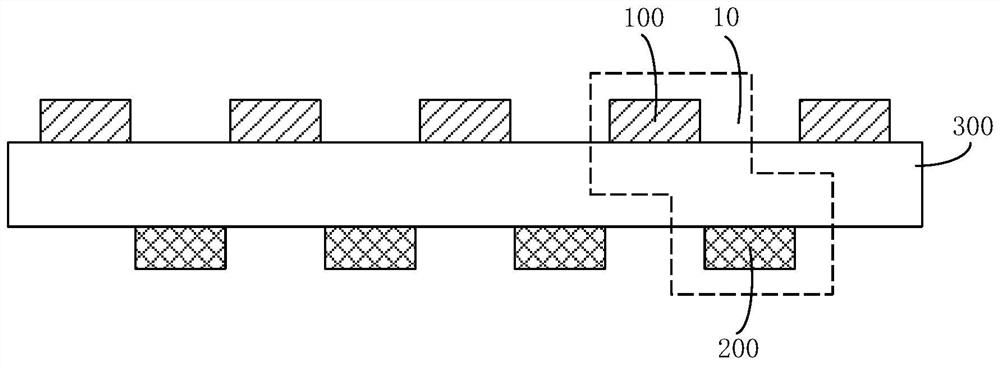

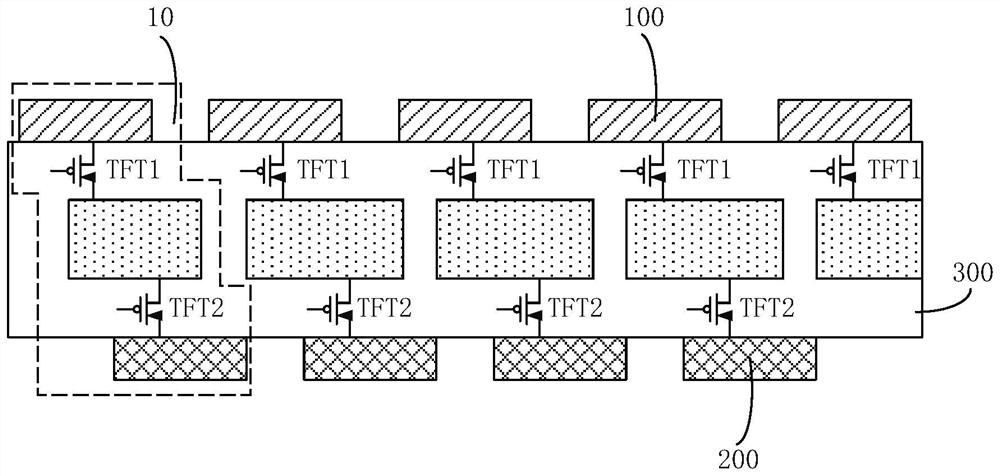

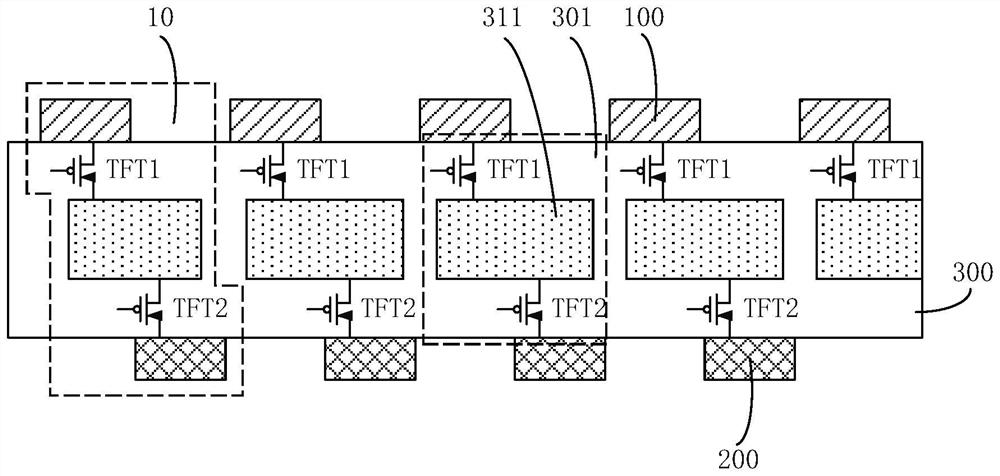

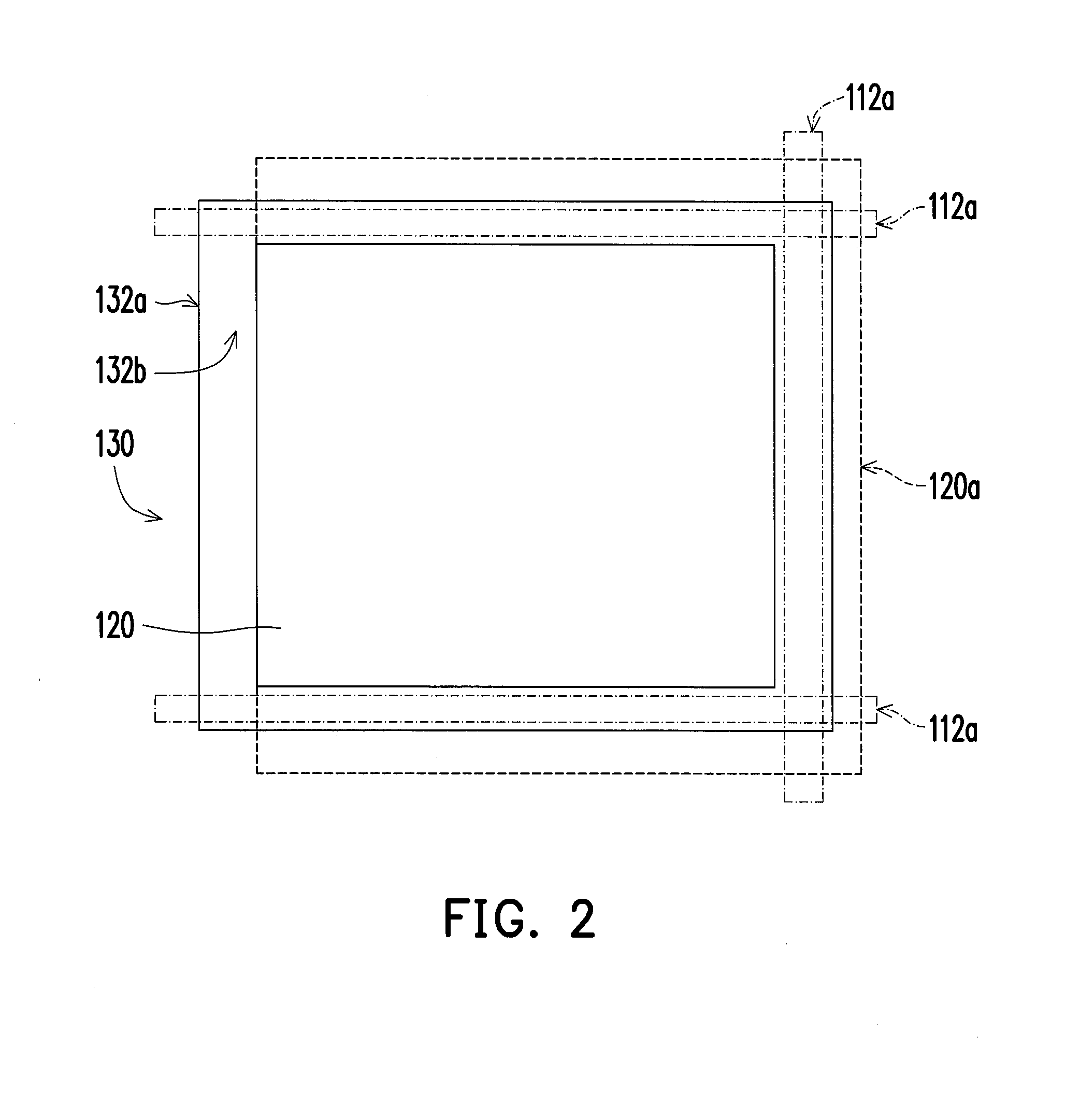

Liquid crystal display device and electronic apparatus comprising it

InactiveUS6897841B2Good thinnessReduce areaStatic indicating devicesSolid-state devicesLiquid-crystal displaySemiconductor chip

A liquid crystal display device enabling realization of greater thinness, smaller area, and narrower frame and an electronic device using the same are provided. For this purpose, the liquid crystal display device of the present invention comprises a first substrate, a pixel unit formed on the first substrate and having pixels arranged in a matrix, a second substrate arranged facing the first substrate, a liquid crystal composition held between the first substrate and the second substrate, and peripheral circuits formed on the first substrate for writing pixel signals to the pixel unit, at least part of the peripheral circuits of the above peripheral circuits being formed by thin film transistors on the first substrate, the remaining part of the peripheral circuits of the above peripheral circuits being formed by semiconductor chips, and the semiconductor chips being arranged on the first substrate so that at least part of the semiconductor chips overlap the regions of the peripheral circuits formed by the thin film transistors.

Owner:SONY CORP

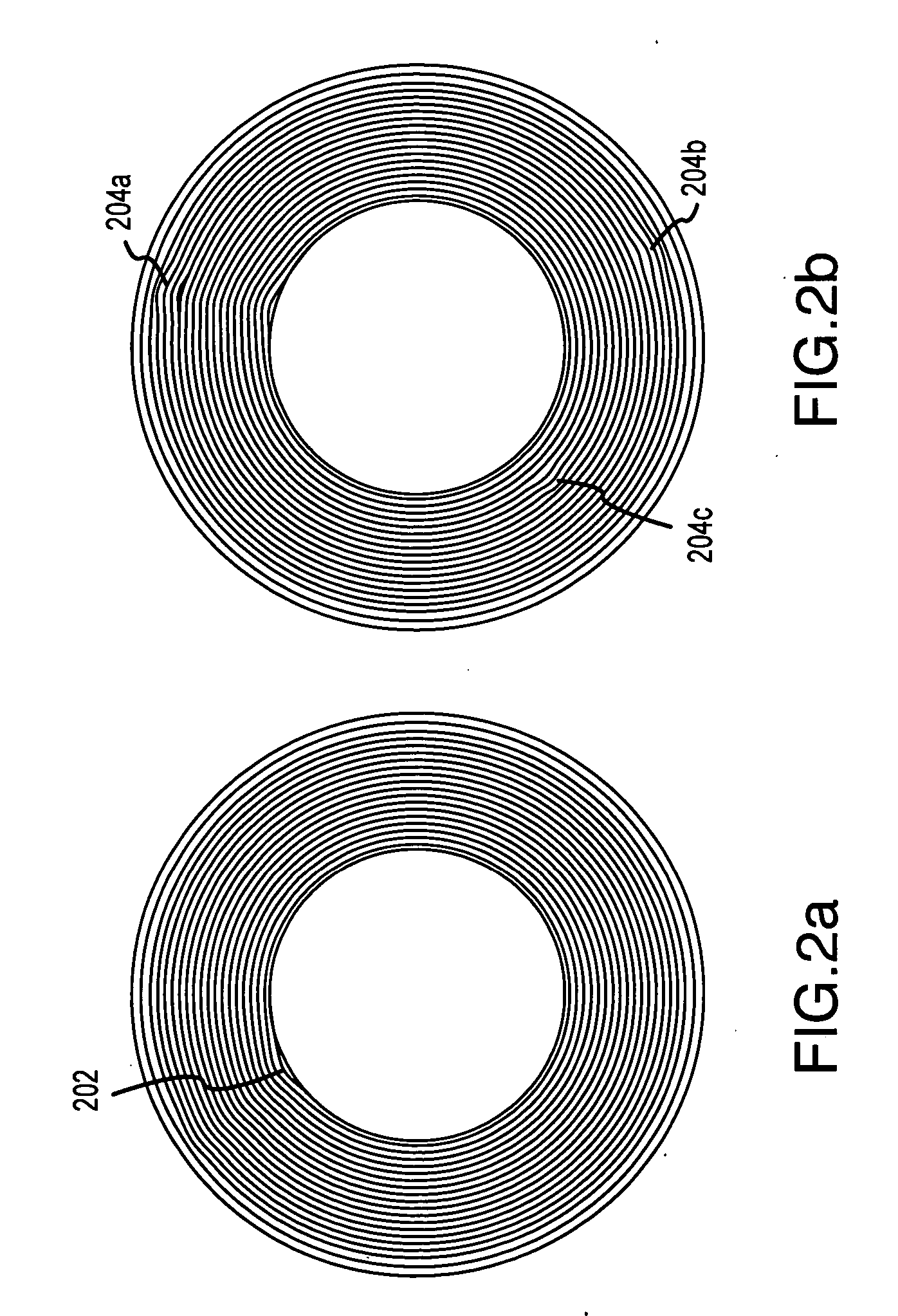

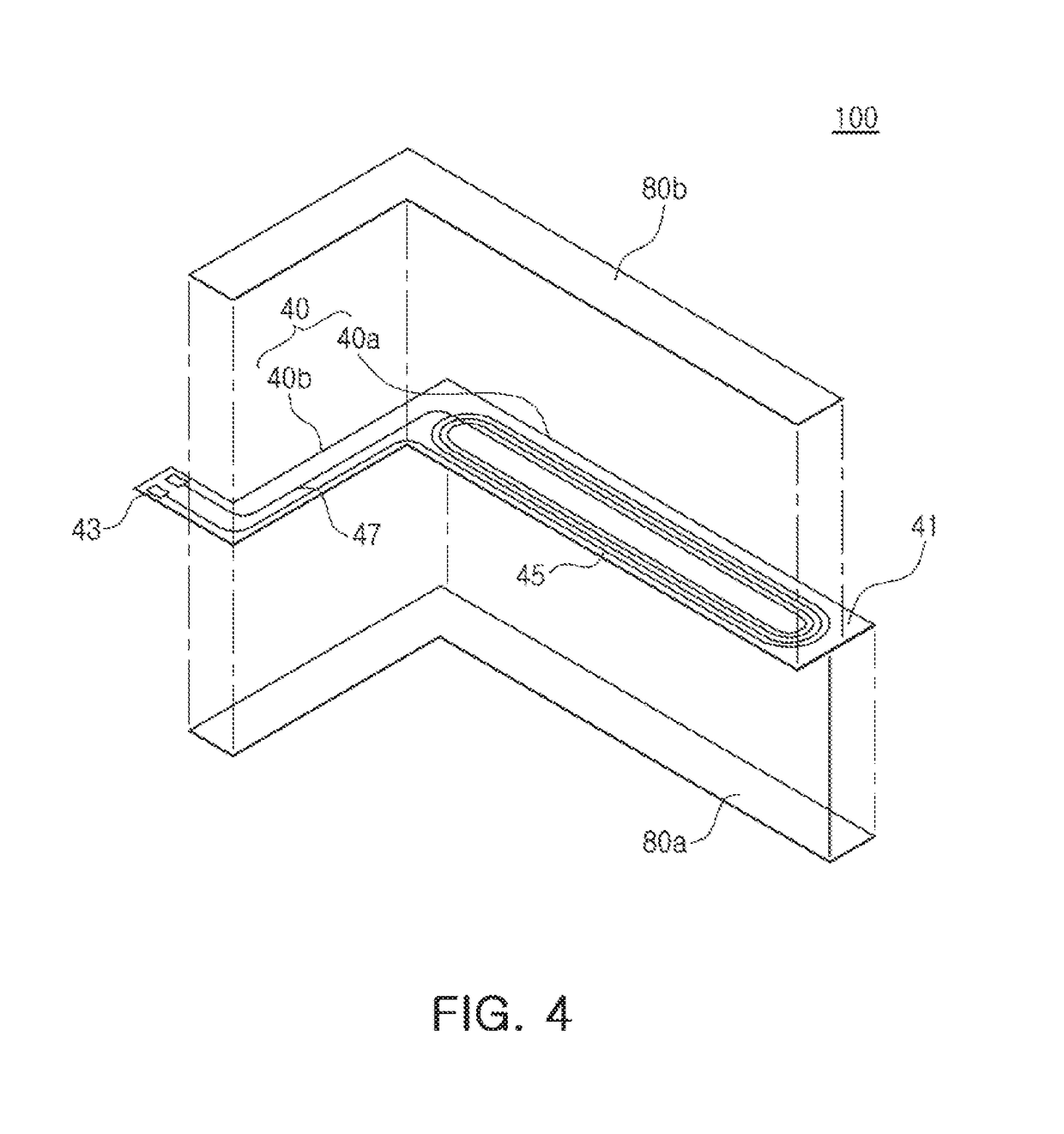

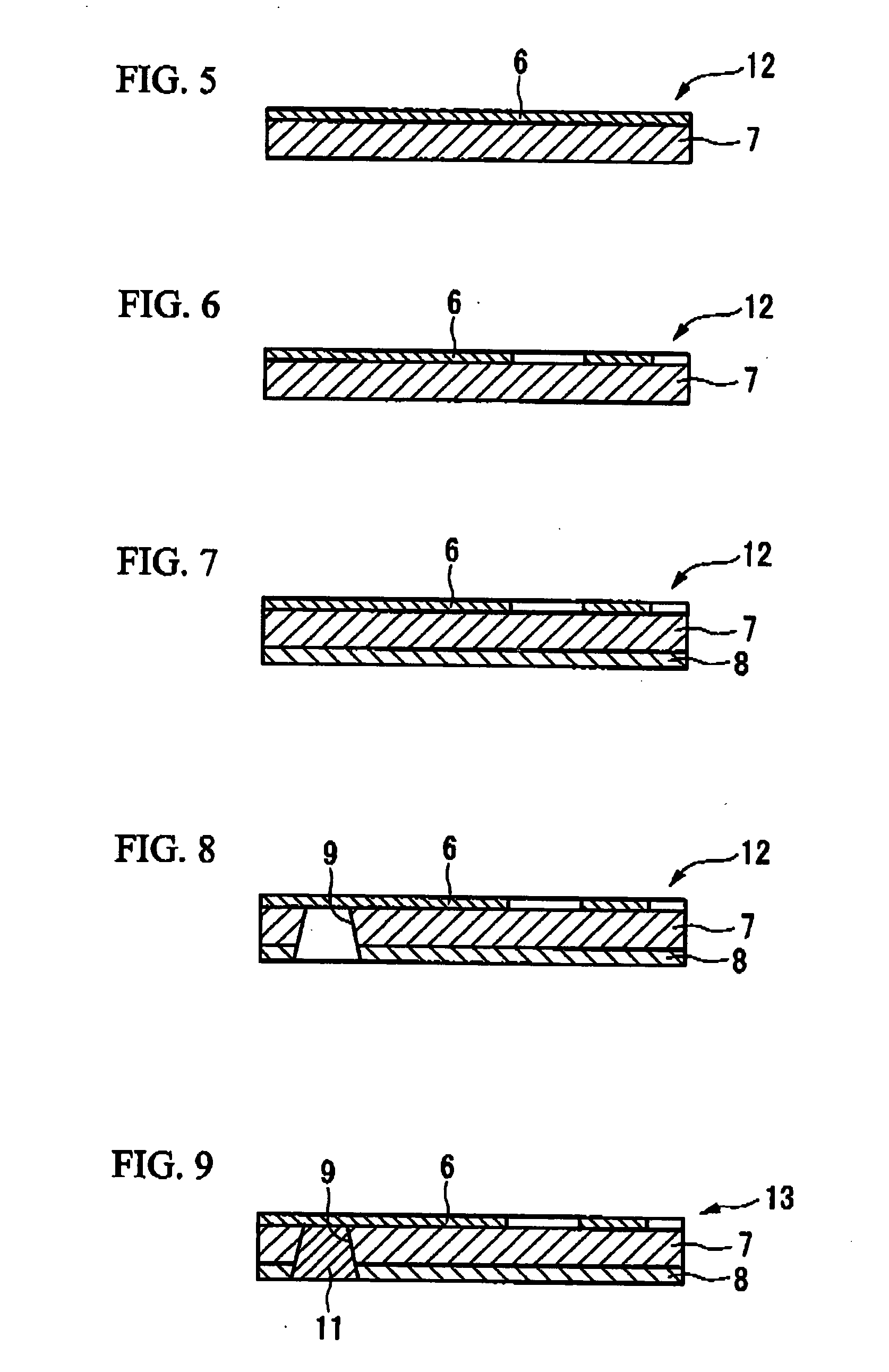

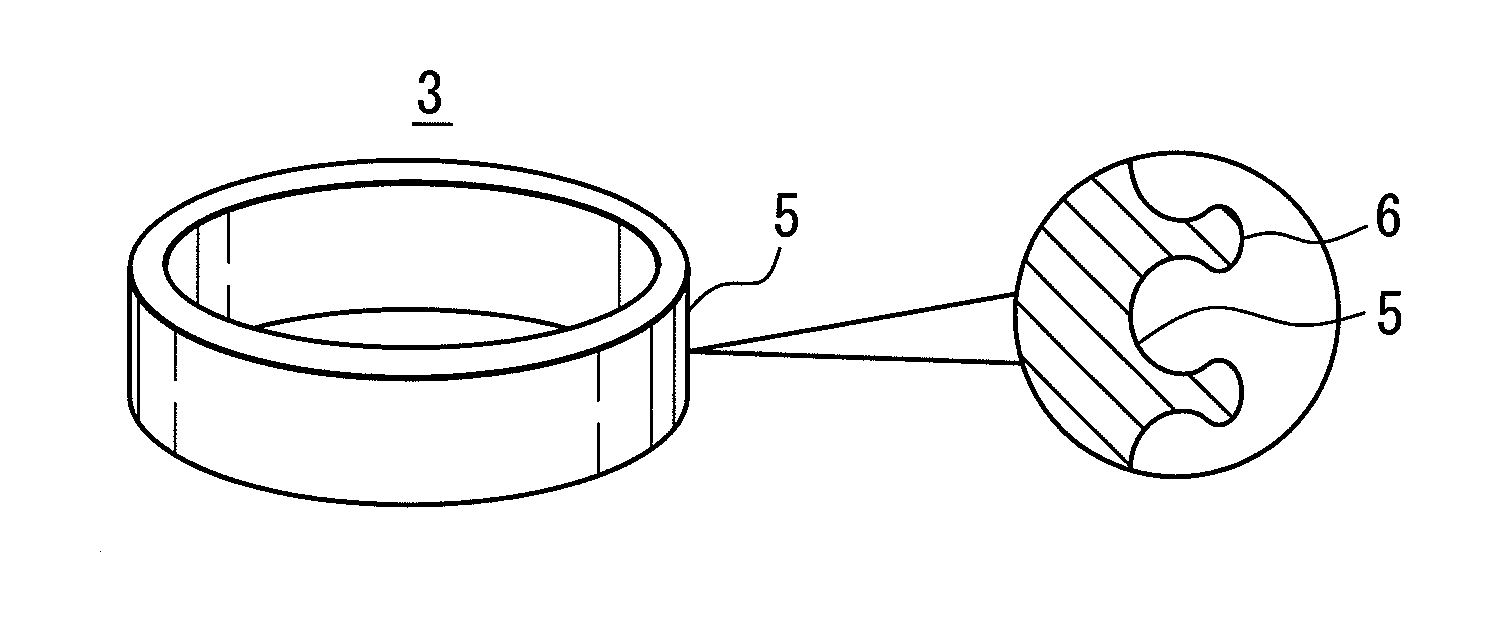

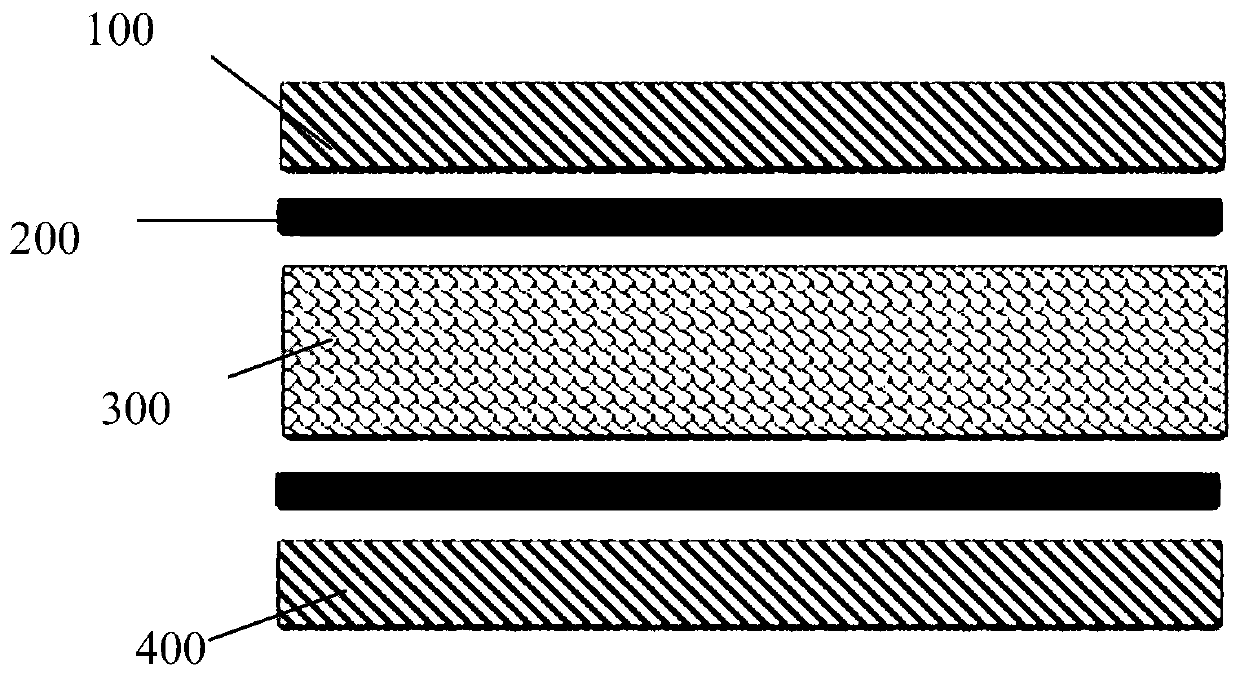

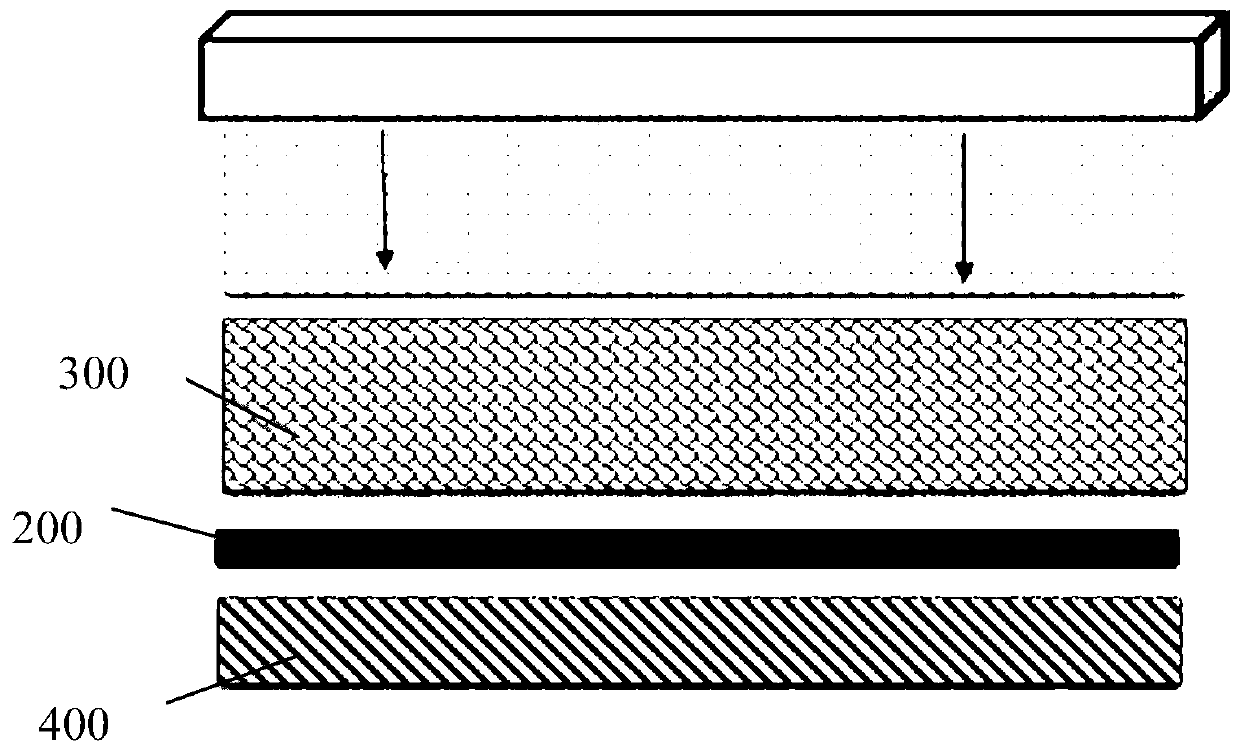

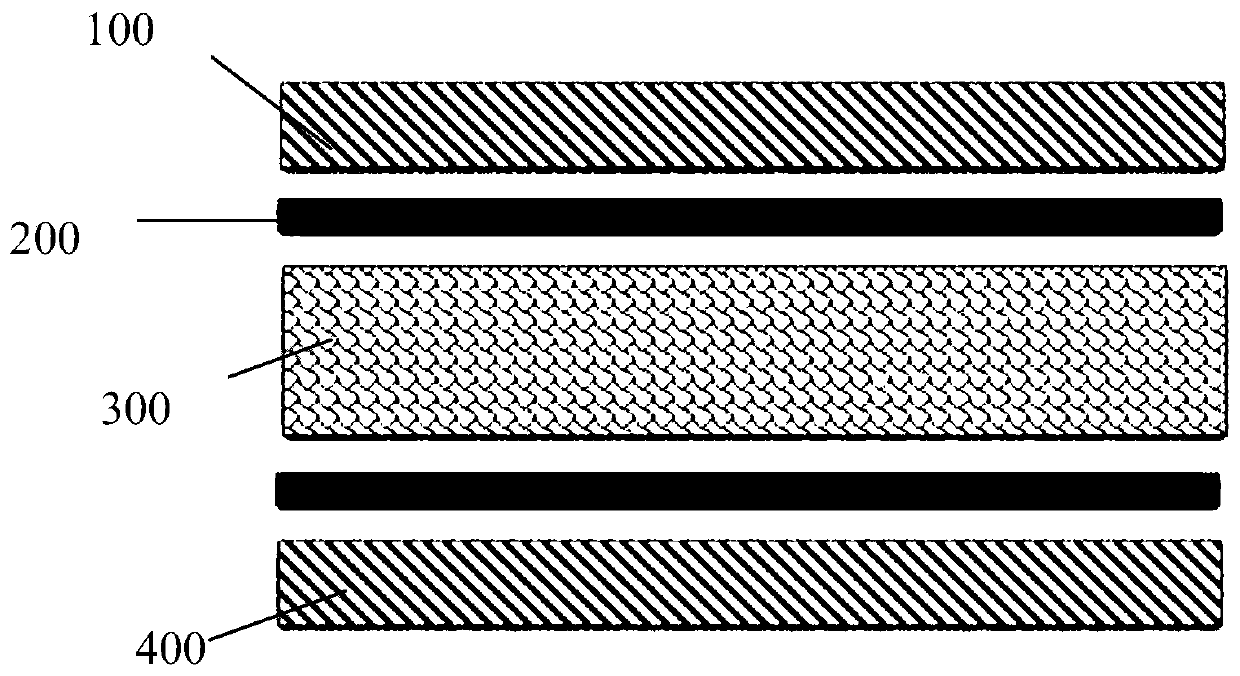

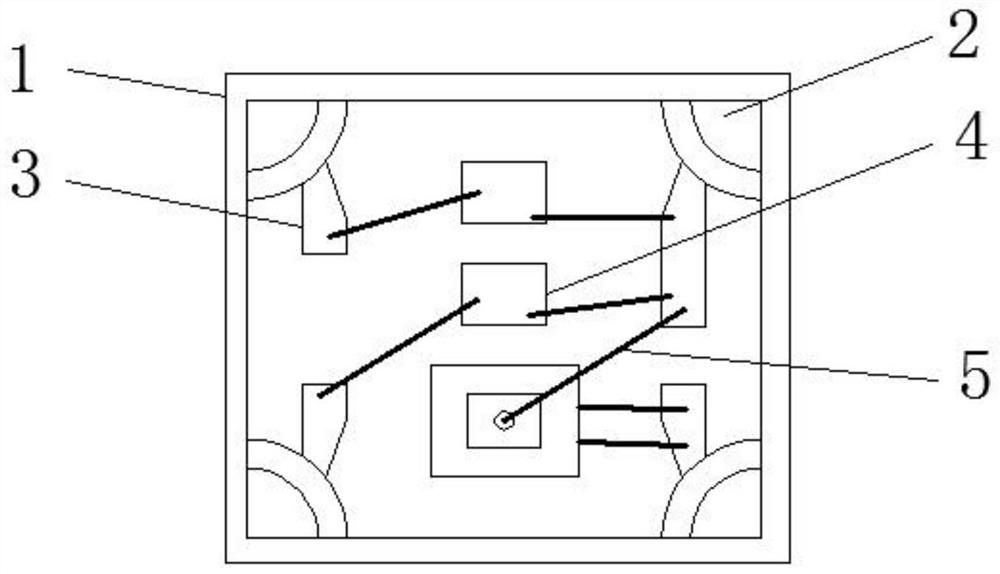

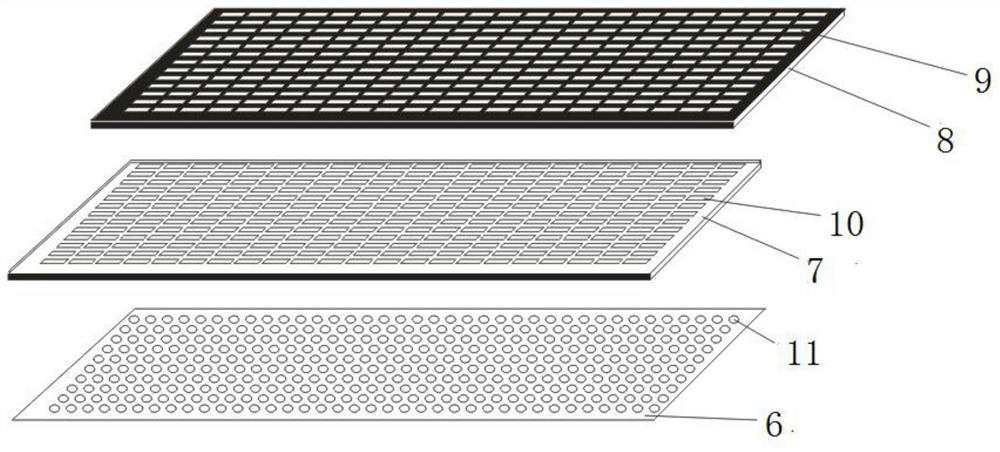

Wave Absorber and Manufacturing Method of Wave Absorber

InactiveUS20080212304A1High reflection attenuation propertyEffective absorptionPrinted circuit assemblingMagnetic/electric field screeningHigh resistanceUltrasound attenuation

The problem of the present invention is to offer a wave absorber that has reflection attenuation capability sufficient to enable prevention of communication disturbances due to reflection and the like of EM waves, that enables greater thinness and lighter weight, and that has wide-band attenuation properties, as well as a manufacturing method of the wave absorber. The wave absorber of the present invention has a structure which sequentially laminates a grid-like conductor layer composed of an electric conductor, a first dielectric layer, a high-resistance conductor layer having a surface resistivity within a prescribed range, a second dielectric layer, and a pattern layer having multiple patterns composed of an electric conductor, wherein each pattern in said pattern layer differs in either or both of size and form relative to another adjacent pattern.

Owner:MITSUBISHI GAS CHEM CO INC

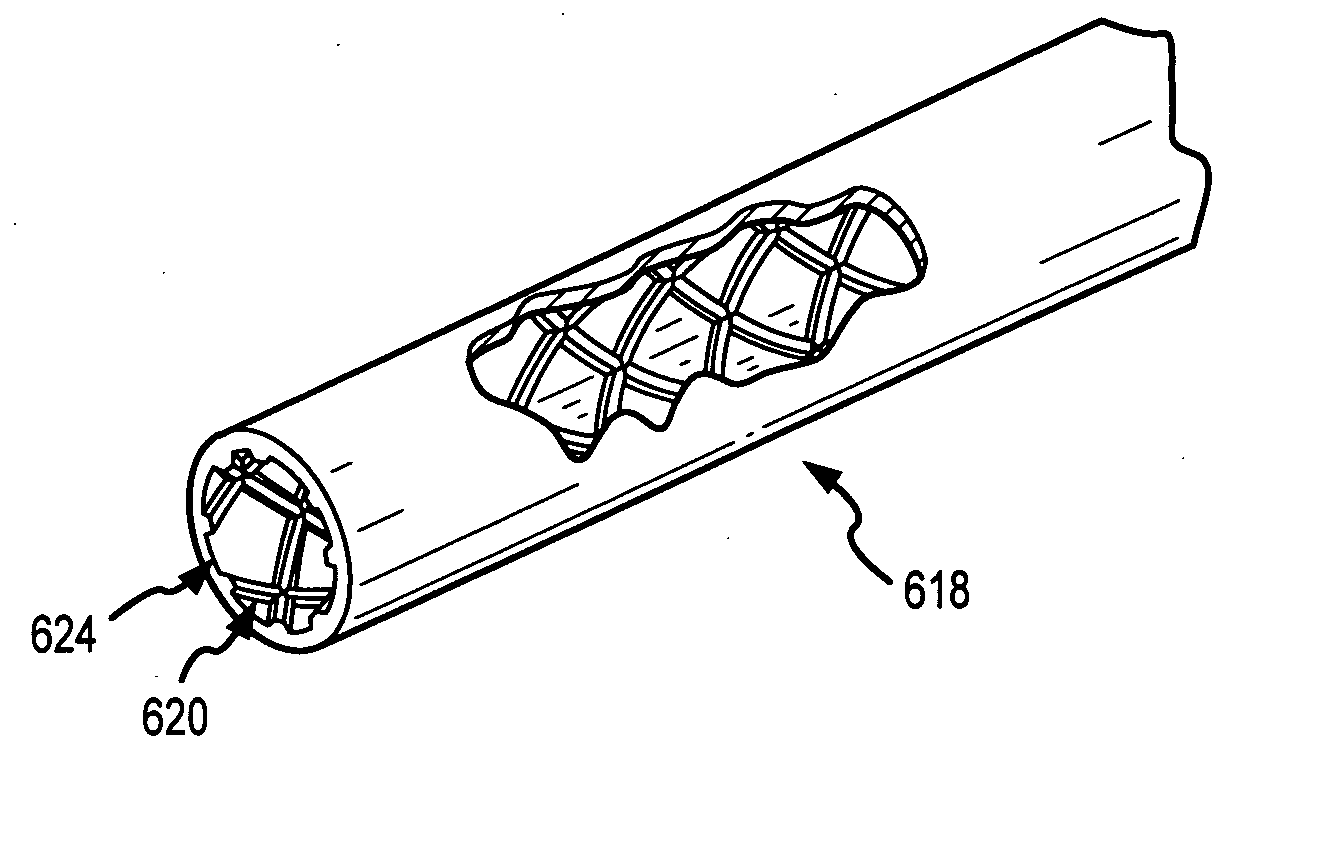

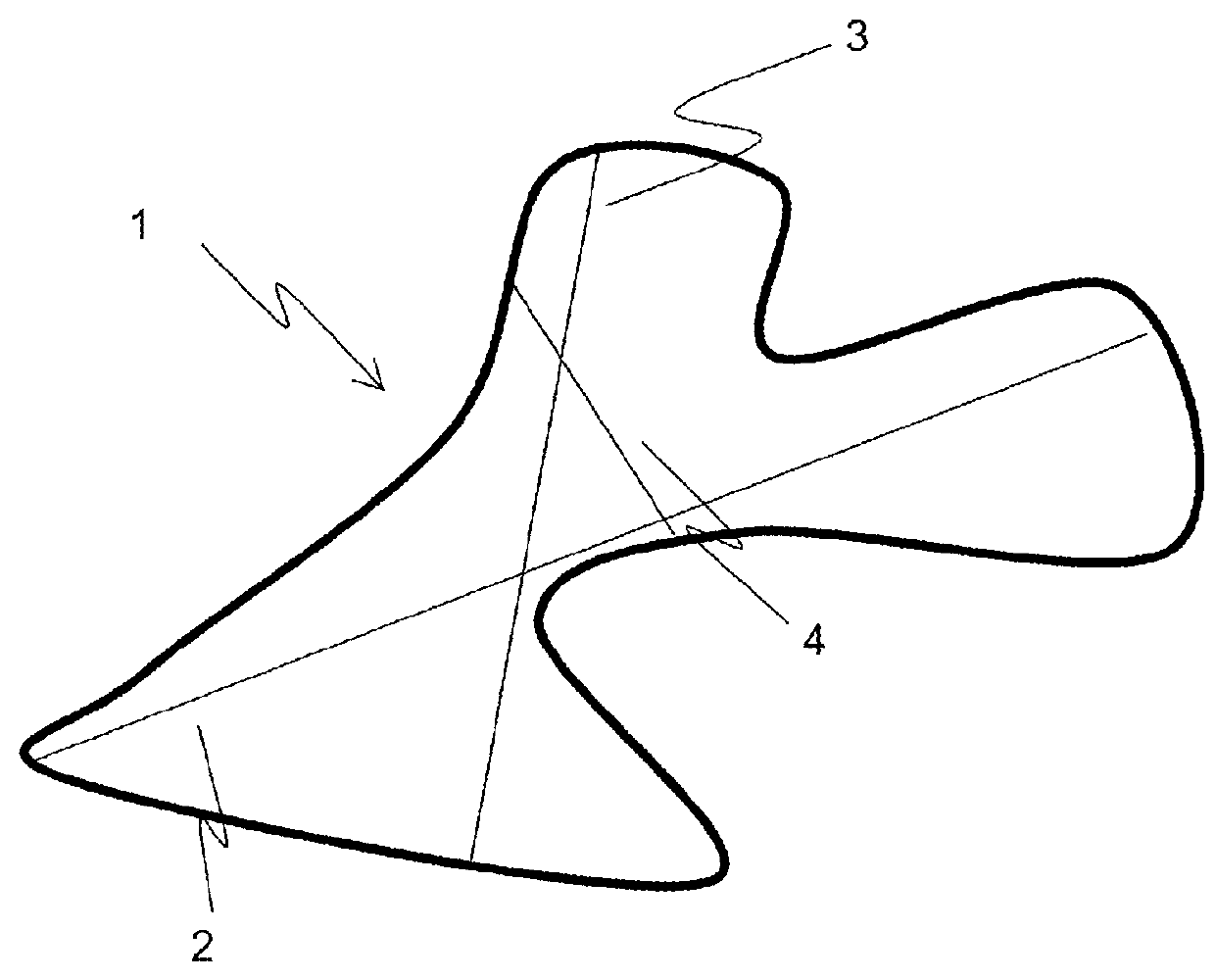

High performance composite tubular structures

InactiveUS20050196570A1Improve performanceLight and more resistant to buckling-relatedLabelling non-rigid containersLayered productsEngineering

This invention relates generally to the design and manufacture of high performance, composite, tubular structures. More specifically, the invention relates to a high performance, composite, tubular structure that utilizes an integral pattern of ribs on the internal diameter (“ID”) or outer diameter (“OD”) surface of the tube. The present invention provides high performance, composite, tubular structures that are both lighter and stiffer than conventional tubes. In general, the present invention incorporates unconventional features into the design of tubular structures, to greatly enhance performance. For example, in accordance with one preferred embodiment of the present invention, tubular structures are enhanced by incorporating small, stabilizing, raised ribs on the ID of the tubes.

Owner:VYATEK SPORTS

CMP Polishing Liquid and Polishing Method

InactiveUS20090094901A1Improve finenessGood thinnessPigmenting treatmentOther chemical processesMetalMaterials science

A CMP polishing liquid being capable of using in a chemical mechanical polishing comprising of: a first chemical mechanical polishing step of polishing a conductive substance layer of a substrate having an interlayer insulation film containing convex and concave regions on a surface thereof, a barrier layer coating along the surface of the interlayer insulation film, and the conductive substance layer coating the barrier layer while filling the concave regions, and thus exposing the barrier layer in the convex regions; and a second chemical mechanical polishing step of exposing the interlayer insulation film in the convex regions by polishing the barrier layer exposed in the first chemical mechanical polishing step; characterized in that a difference (B)−(A) is 650 {acute over (Å)} or less,wherein the (A) is a polishing amount of the interlayer insulation film in a field area when the interlayer insulation film in the field area having a width of 1,000 μm or more of the interlayer insulation film region formed on the substrate is polished to a depth of 400 {acute over (Å)} or more; andthe (B) is a polishing amount of the interlayer insulation film in a stripe-shaped patterned area having a total width of 1,000 μm or more wherein a wiring metal region having a width of 90 μm and the interlayer insulation film region having a width of 10 μm are aligned alternately on the substrate when the interlayer insulation film in the field area having the width of 1,000 μm or more of the interlayer insulation film region formed on the substrate is polished to a depth of 400 {acute over (Å)} or more.

Owner:HITACHI CHEM CO LTD

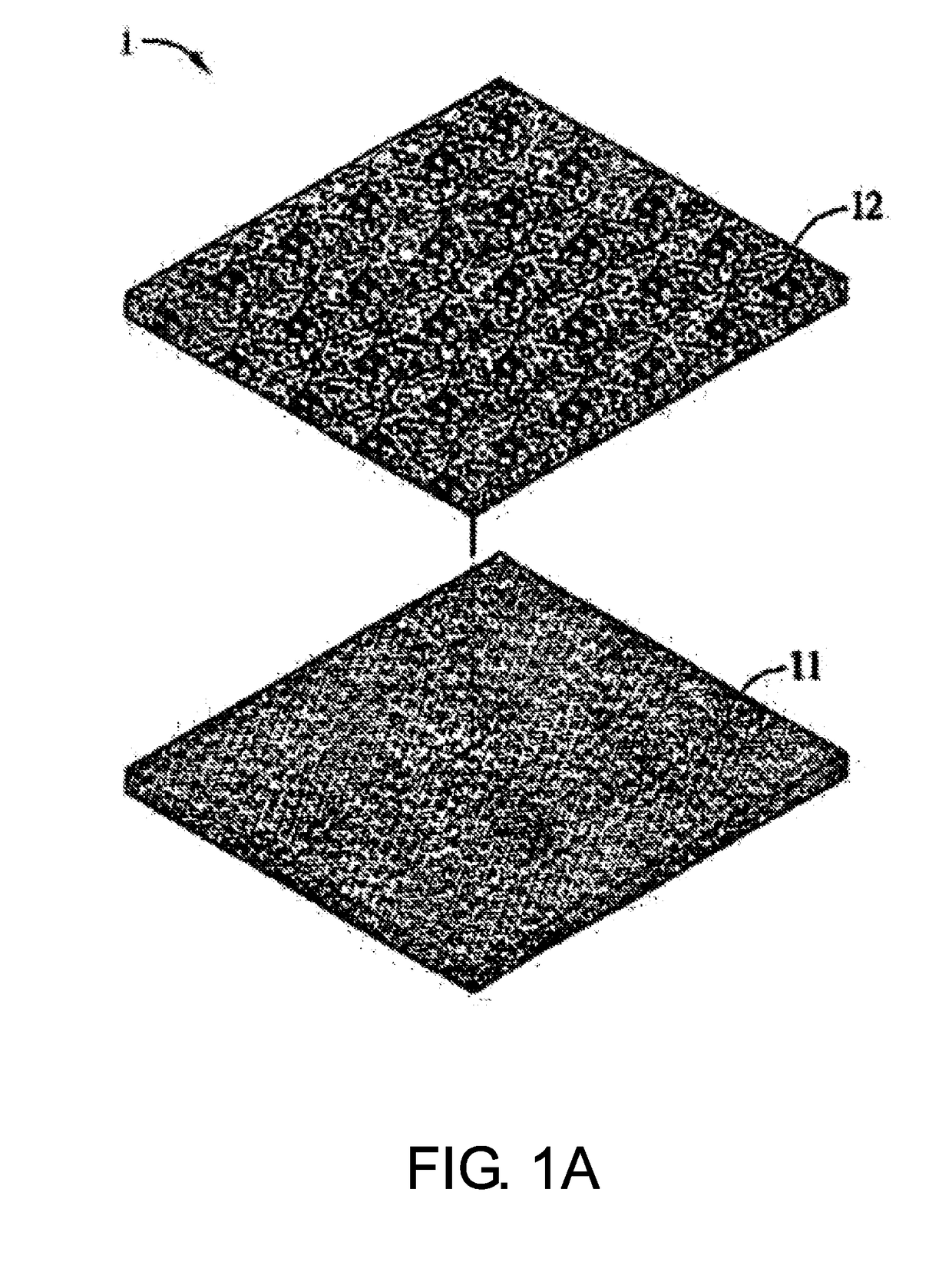

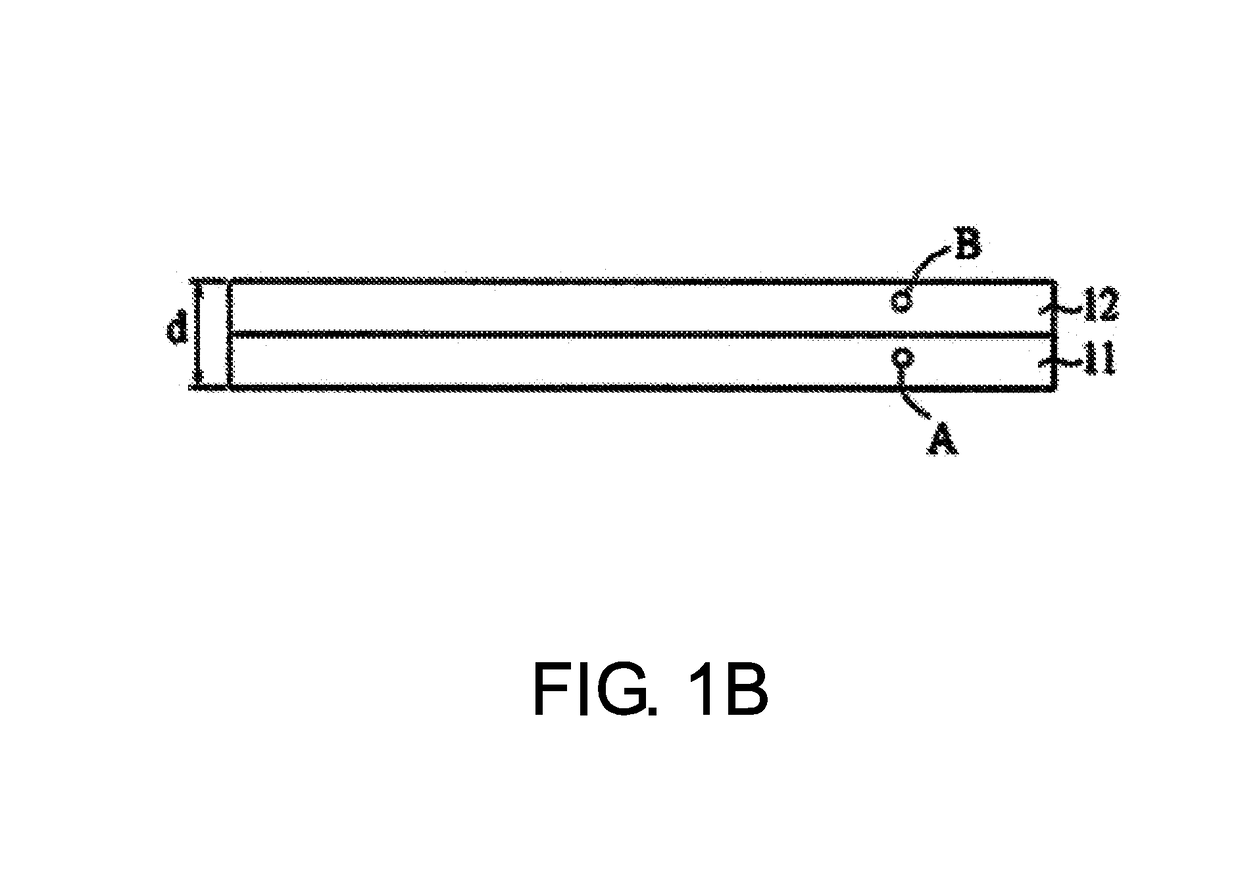

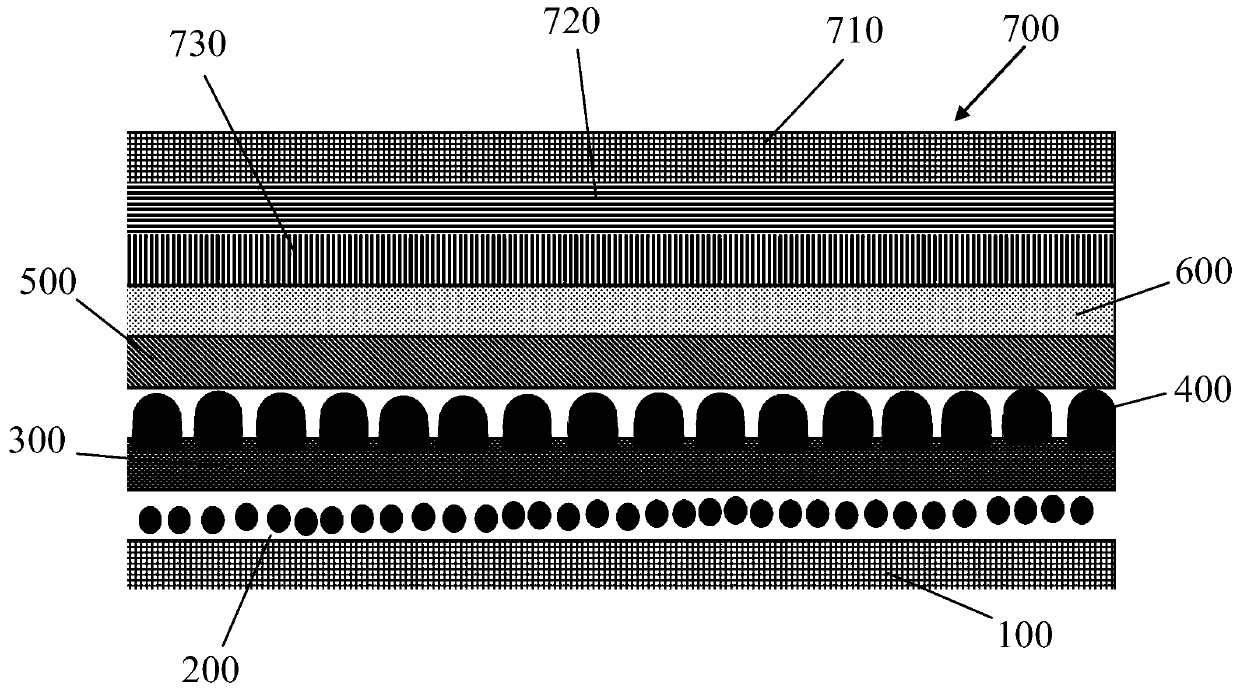

Thermally conductive structure and heat dissipation device

InactiveUS20180187987A1Fast conductionImprove thermal conductivitySemiconductor/solid-state device detailsIndirect heat exchangersCarbon nanotubeGraphene

A thermally conductive structure and a heat dissipation device are provided. The thermally conductive structure comprises a first thermally conductive layer and a second thermally conductive layer. The first thermally conductive layer comprises a graphene material and first carbon nanotubes, and the first carbon nanotubes are dispersed in the graphene material. The second thermally conductive layer is stacked on the first thermally conductive layer, and comprises a porous material and second carbon nanotubes, and the second carbon nanotubes are dispersed in the porous material. The heat dissipation device comprises the thermally conductive structure and a heat dissipation structure. The thermally conductive structure is in contact with a heat source, and the heat dissipation structure is connected to the thermally conductive structure. The thermally conductive structure and the heat dissipation device are characterized by thinness, and meet the need of light weight and thinness in modern thinned electronic products.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

Wave absorber and manufacturing method of wave absorber

InactiveUS7864095B2Light weightSmall fluctuationPrinted circuit assemblingMagnetic/electric field screeningUltrasound attenuationElectrical resistance and conductance

The problem of the present invention is to offer a wave absorber that has reflection attenuation capability sufficient to enable prevention of communication disturbances due to reflection and the like of EM waves, that enables greater thinness and lighter weight, and that has wide-band attenuation properties, as well as a manufacturing method of the wave absorber. The wave absorber of the present invention has a structure which sequentially laminates a grid-like conductor layer composed of an electric conductor, a first dielectric layer, a high-resistance conductor layer having a surface resistivity within a prescribed range, a second dielectric layer, and a pattern layer having multiple patterns composed of an electric conductor, wherein each pattern in said pattern layer differs in either or both of size and form relative to another adjacent pattern.

Owner:MITSUBISHI GAS CHEM CO INC

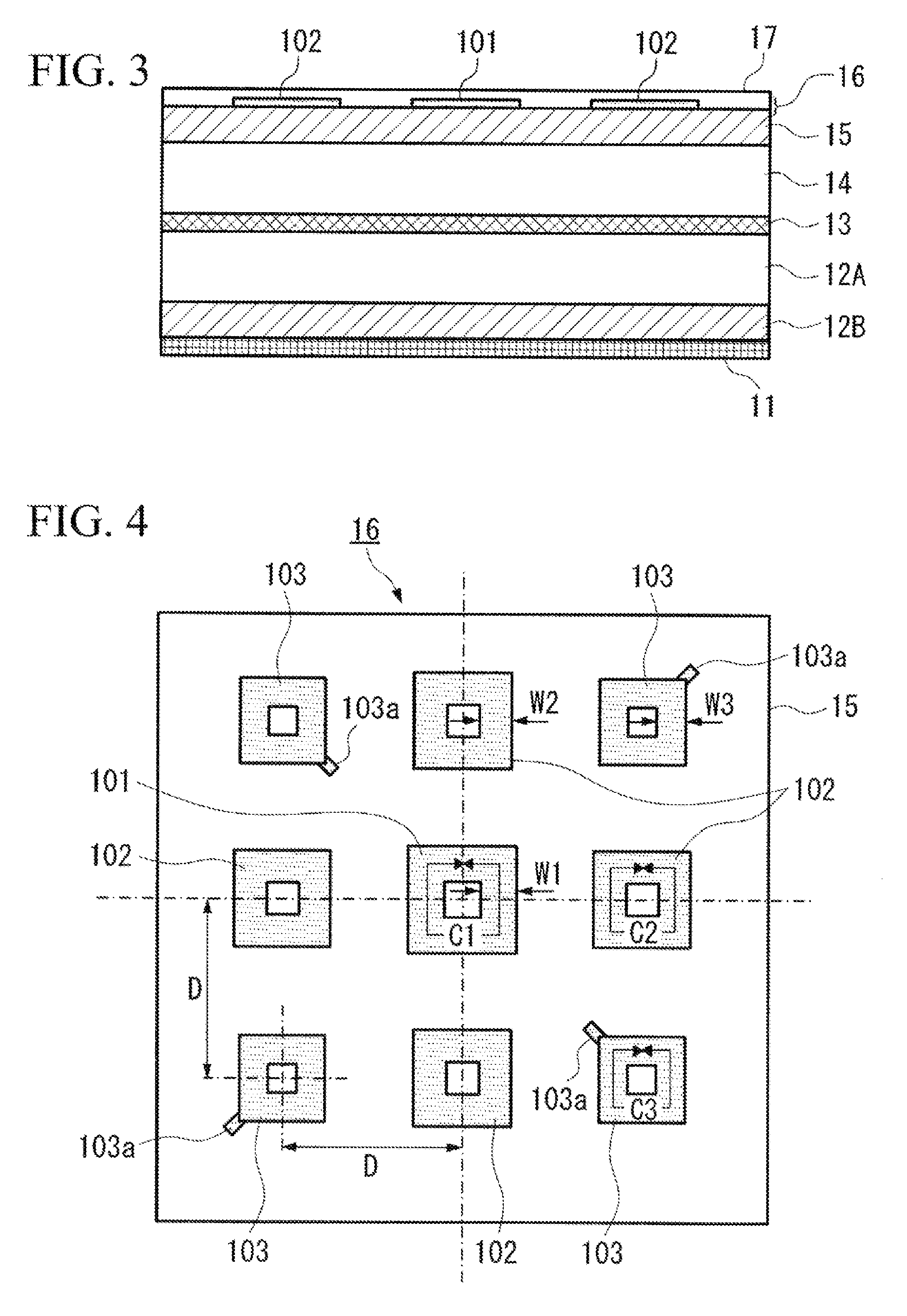

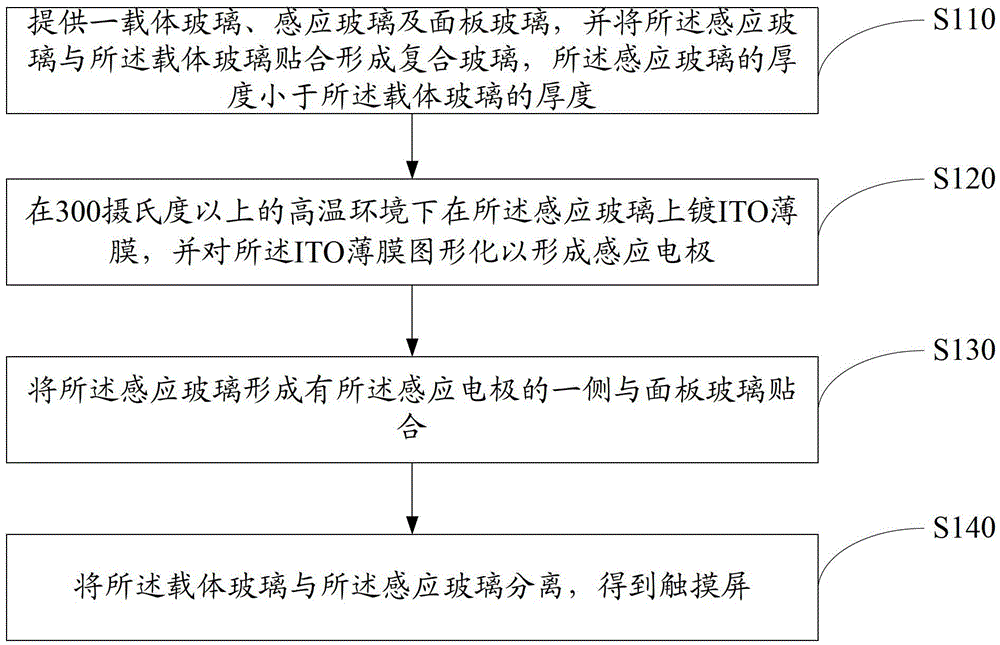

Manufacturing method of capacitive touch screen

ActiveCN103309538AReduce thicknessThin and lightInput/output processes for data processingPolyethylene terephthalateTransmittance

A manufacturing method of a capacitive touch screen comprises steps as follows: a piece of induction glass and a piece of carrier glass are attached to form a compound glass structure, the thickness of the induction glass is smaller than that of the carrier glass, and the carrier glass can support and protect the induction glass, so that the induction glass can be prevented from being damaged in the follow-up film coating, heating and attaching processes. The induction glass can be manufactured to be light and thin as required, so that the obtained touch screen is smaller in thickness. The high-temperature resistance of glass is improved greatly when compared with that of a PET (polyethylene terephthalate) material, the induction glass can be plated with an ITO (indium tin oxide) film under the high-temperature environment of above 300 DEG C, a compact thicker conductive film can be formed in the induction glass, and the obtained touch screen has good optical and electrical properties. With the adoption of the manufacturing method of the capacitive touch screen, the lighter and thinner touch screen with good light transmittance can be manufactured.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

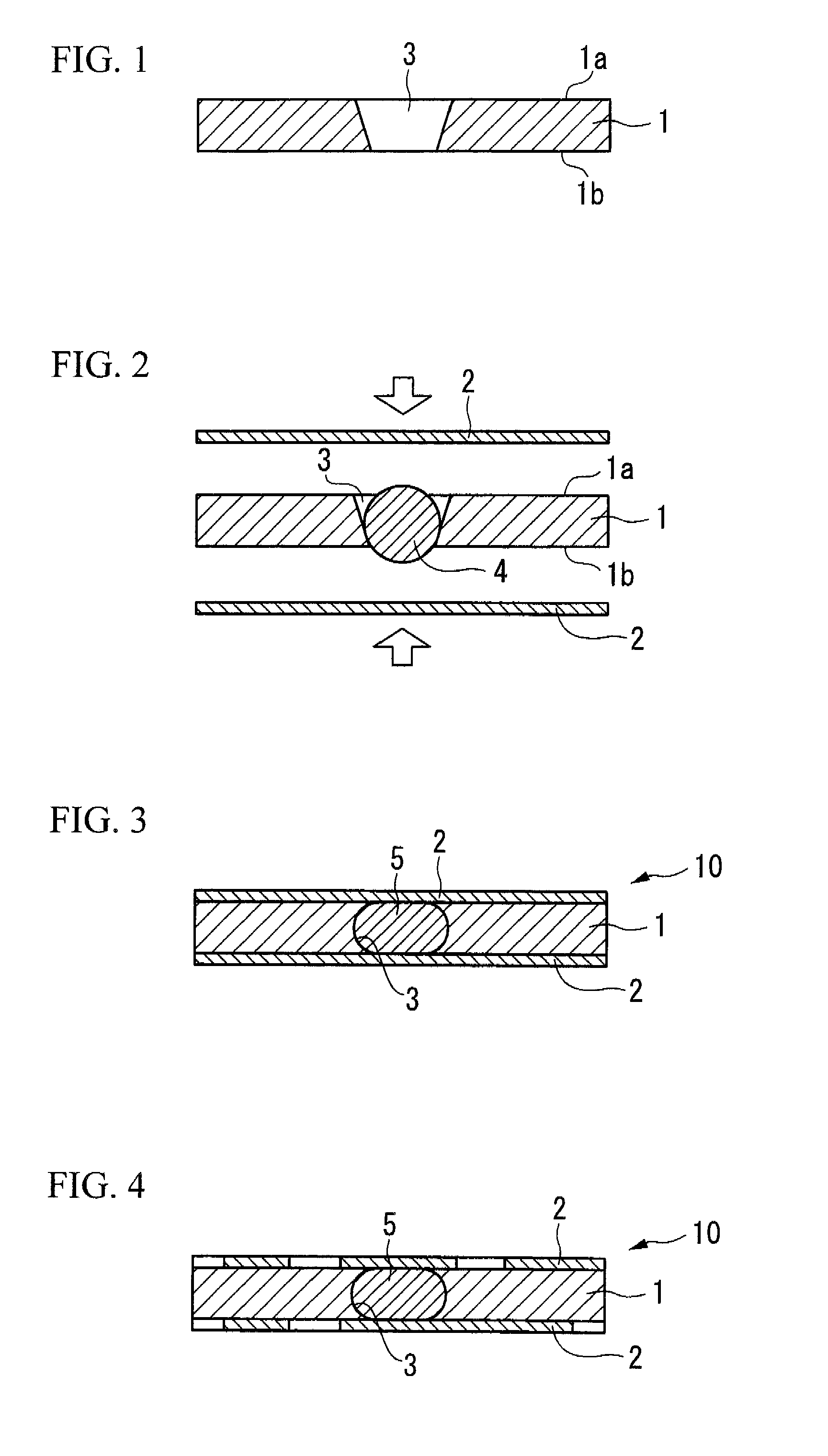

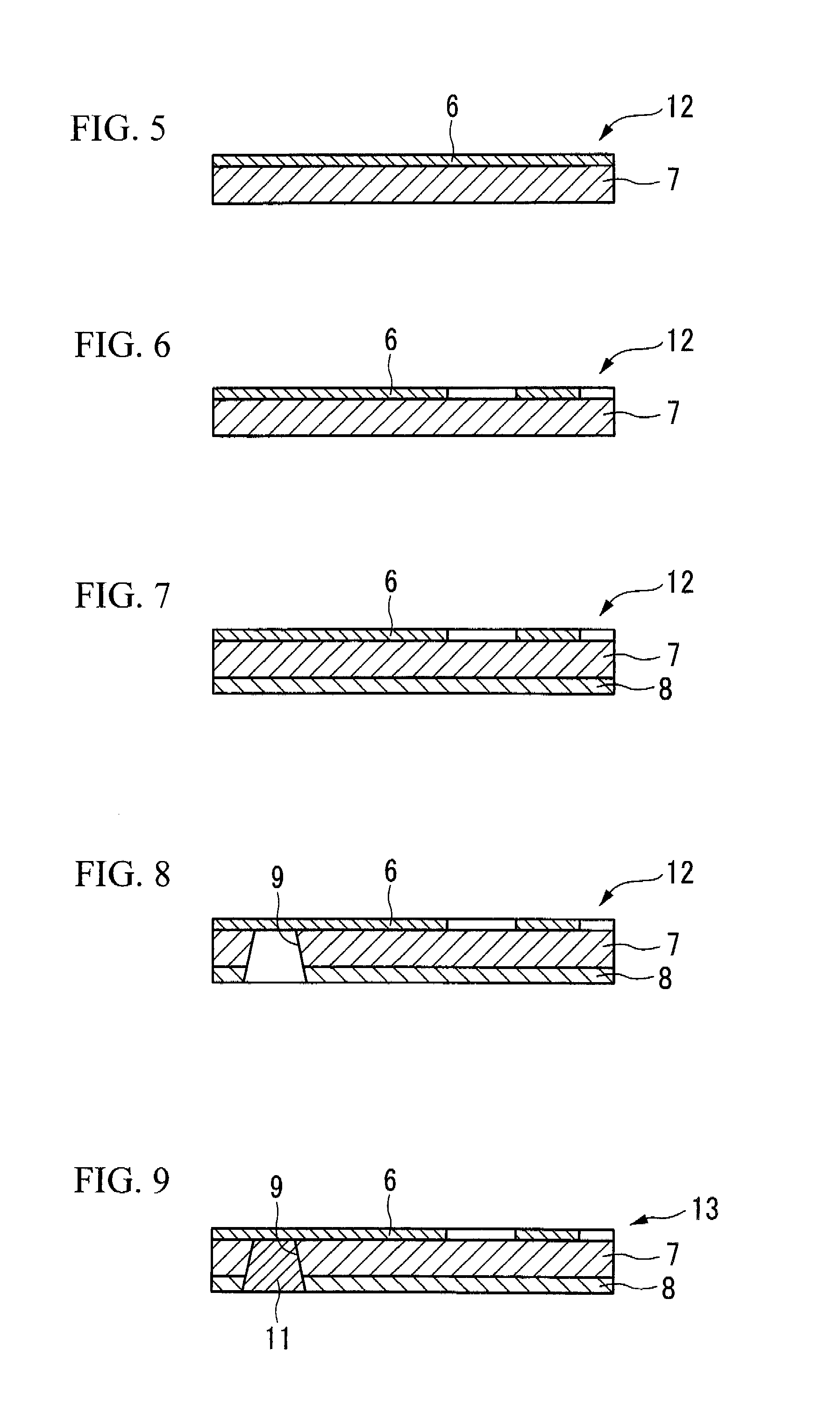

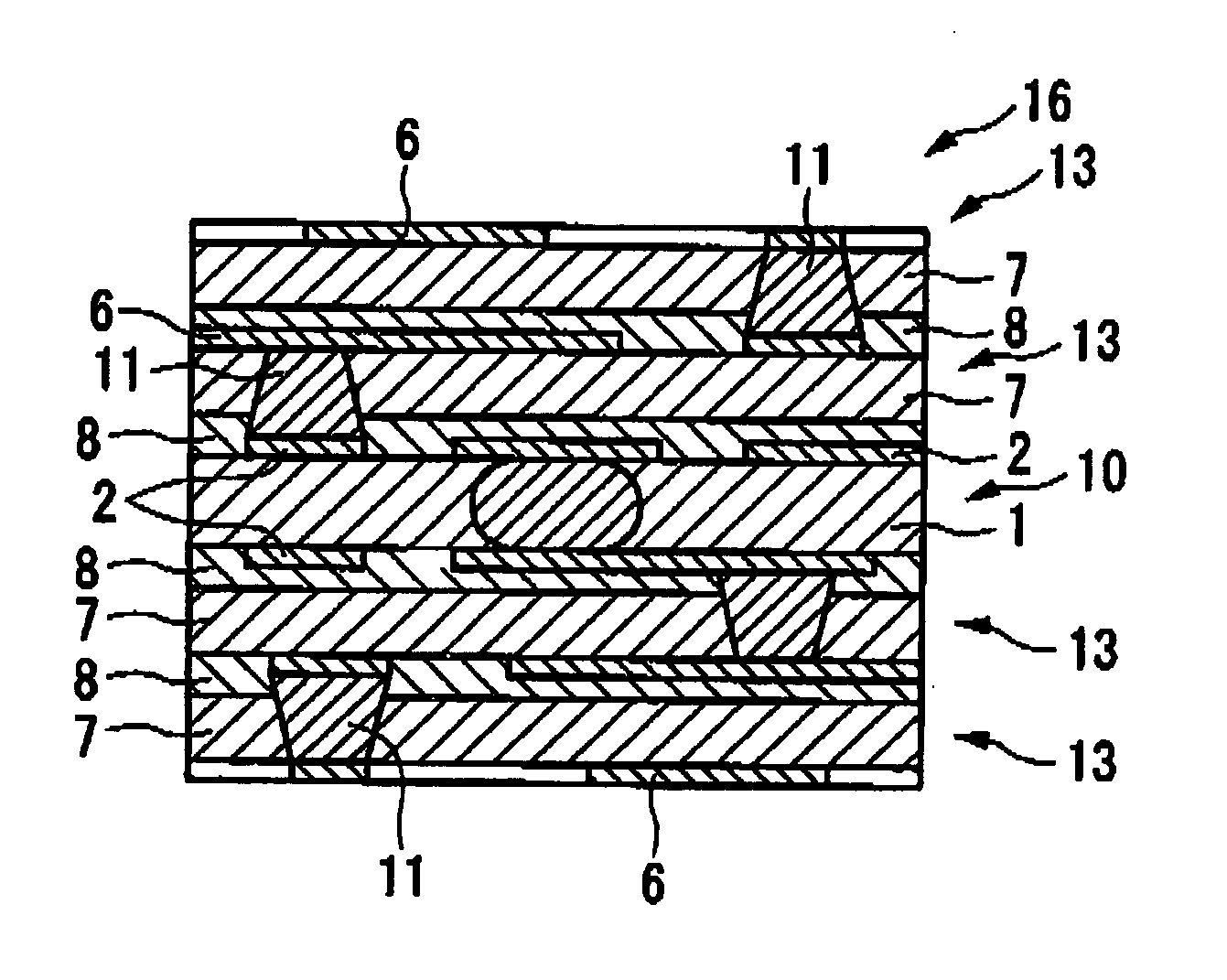

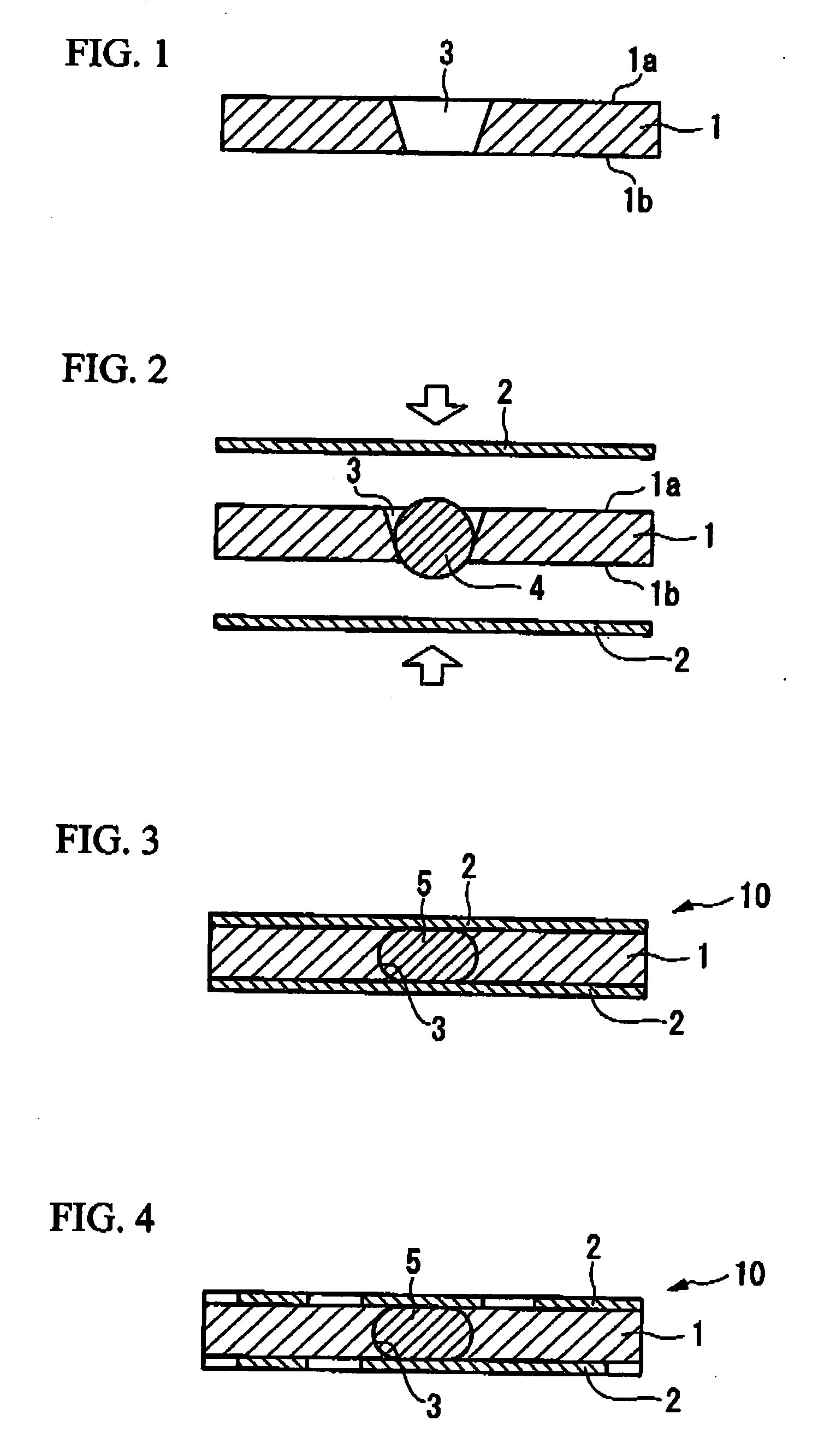

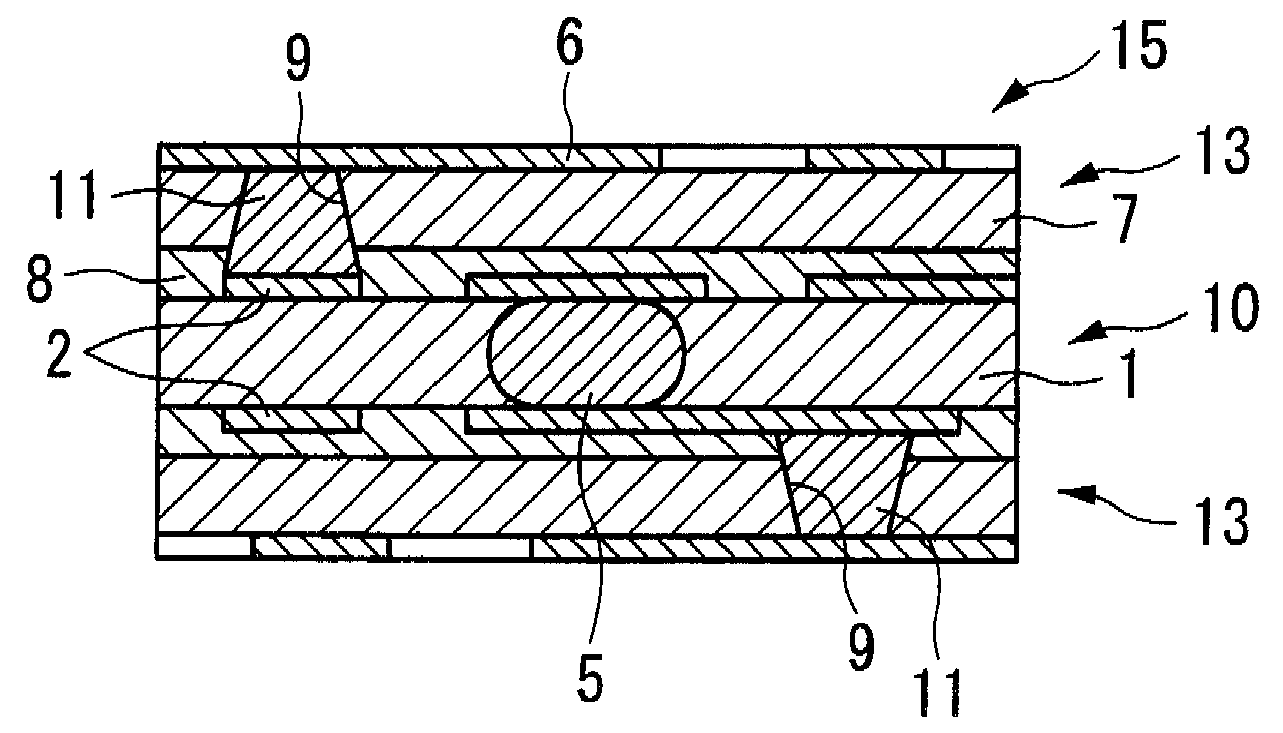

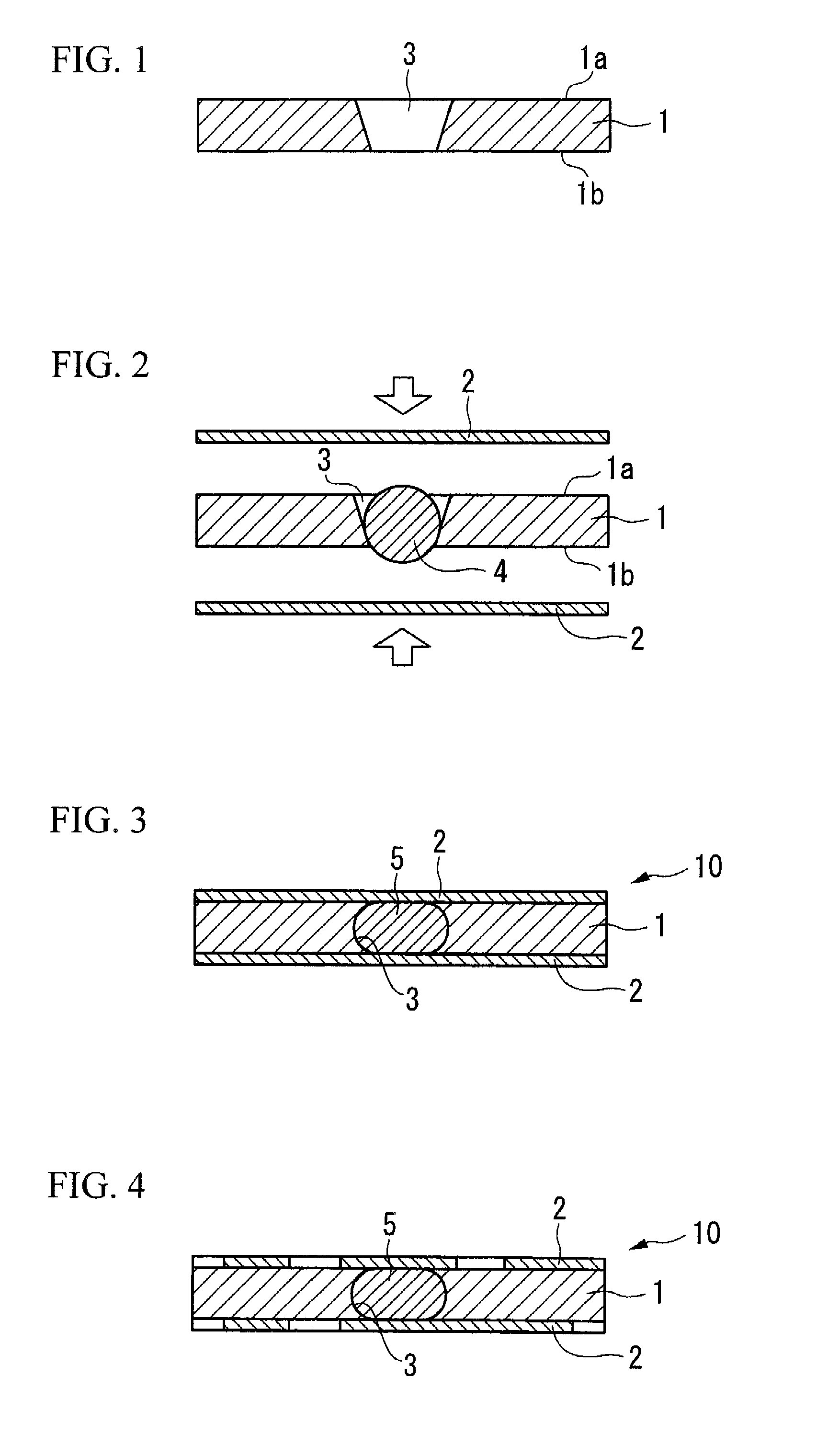

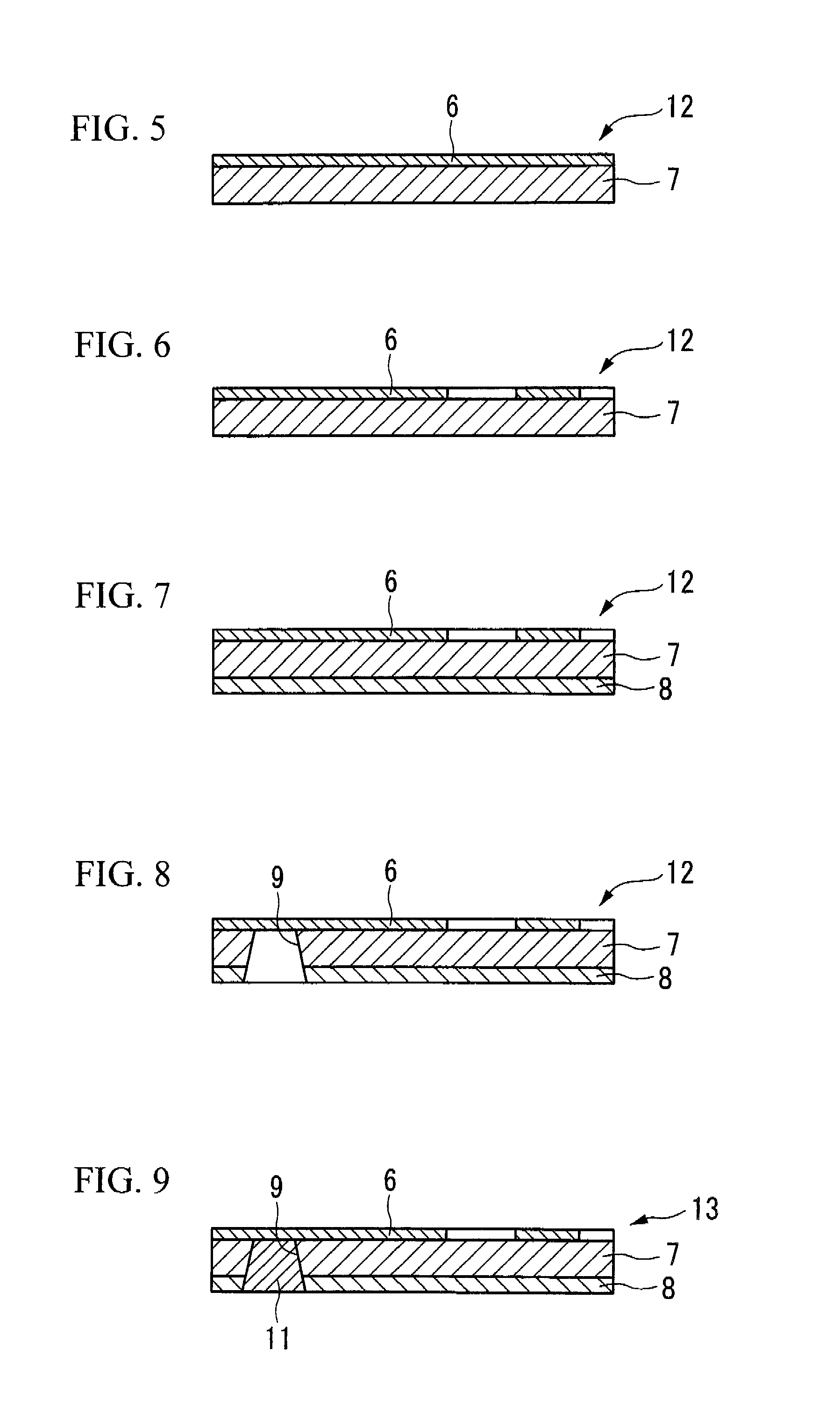

Wiring board, multilayer wiring board, and method for manufacturing the same

InactiveUS20080016685A1Improve compactnessGood thinnessLine/current collector detailsPrinted circuit aspectsEngineeringElectrical and Electronics engineering

A method for manufacturing a wiring board comprising an insulating member, comprising: a penetrating hole formation process of forming a penetrating hole in the insulating member; a placement process of inserting a conductive connecting particle into the penetrating hole; a connecting particle pressing process of disposing the conductive layers on both surfaces of the insulating member, pressing the conductive layers toward the connecting particle in the penetrating hole, and deforming the connecting particle in the pressing direction to obtain the connecting member; and a patterning process of patterning the conductive layers, wherein, in the connecting particle pressing process, the pressing is performed such that the cross-sectional area in the direction along the insulating member surface of at least a portion of the connecting member is greater than the contact area of the connecting member with the conductive layers.

Owner:FUJIKURA LTD

Preparation method of elastic polyester fiber and flax fiber blended yarns by adopting bio-enzyme method

The invention discloses a preparation method of elastic polyester fiber and flax fiber blended yarns by adopting a bio-enzyme method. The weight content of flax fibers is 45 percent to 75 percent and the balance is elastic polyester fibers; the preparation method comprises: pre-treating, blowing, cotton carding, drawing, roving, degumming, bleaching, acid washing, washing and spinning. By adopting the preparation method provided by the invention, the elastic polyester fiber and flax fiber blended yarns with moisture absorption, lightness and thinness, glossiness, air permeability, antibacterial property and mite inhibition property can be prepared. The elastic polyester fiber and flax fiber blended yarns provided by the invention have high spinnability and good elasticity; cloth woven by the elastic polyester fiber and flax fiber blended yarns is light and soft, comfortable and breathable, has sweat-absorbing and antibacterial properties and has elasticity; the cloth has novel and fashionable appearance. The elastic polyester fibers and the flax fibers are blended and the disadvantage of low elasticity of the flax fibers can be made up; a prepared fabric has a comfortable hand feeling and has good elasticity; the style of the blended yarns can be improved and the hand feeling of the blended yarns can be improved.

Owner:JIANGSU HUAXIN LINEN TEXTILE

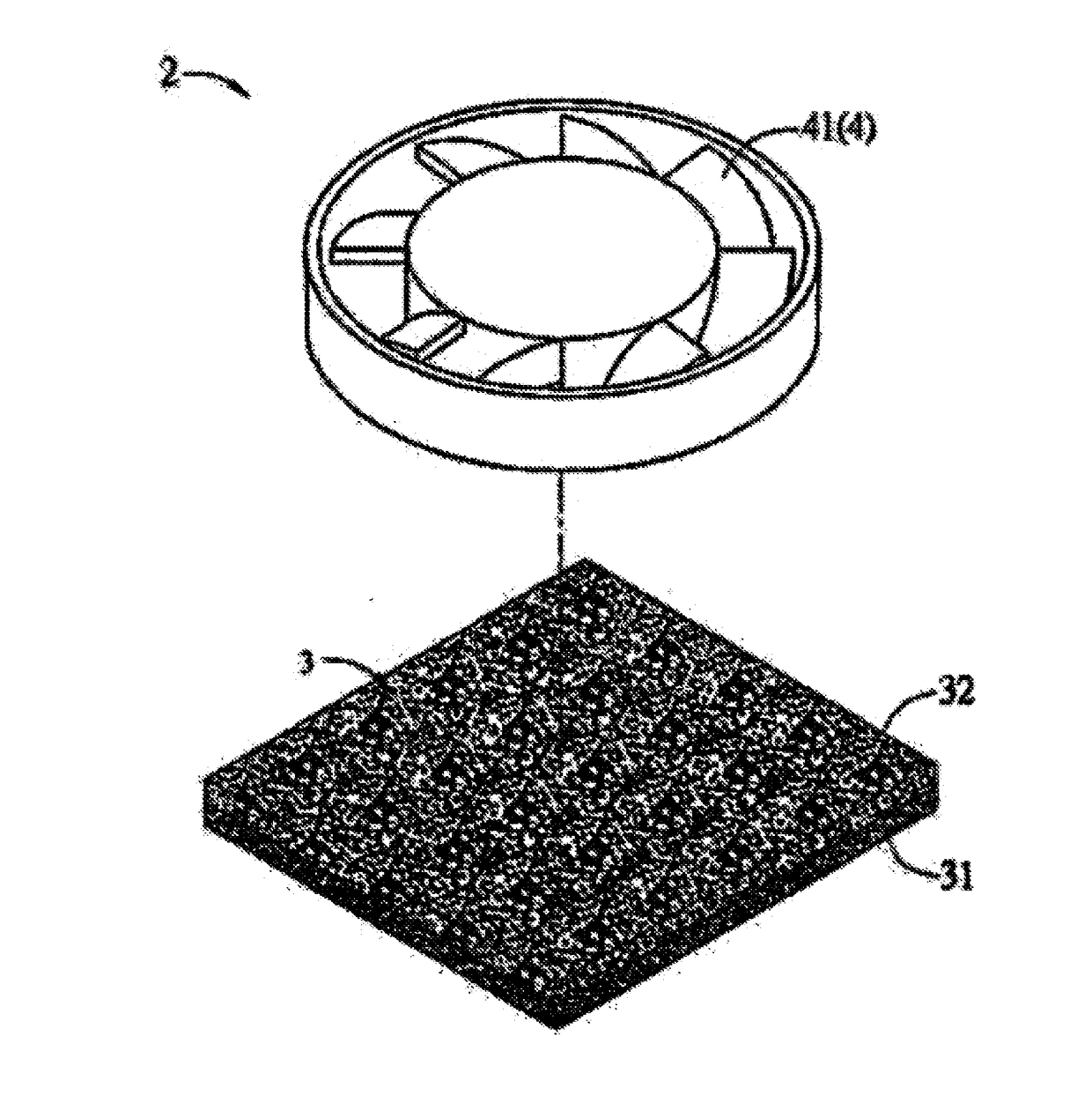

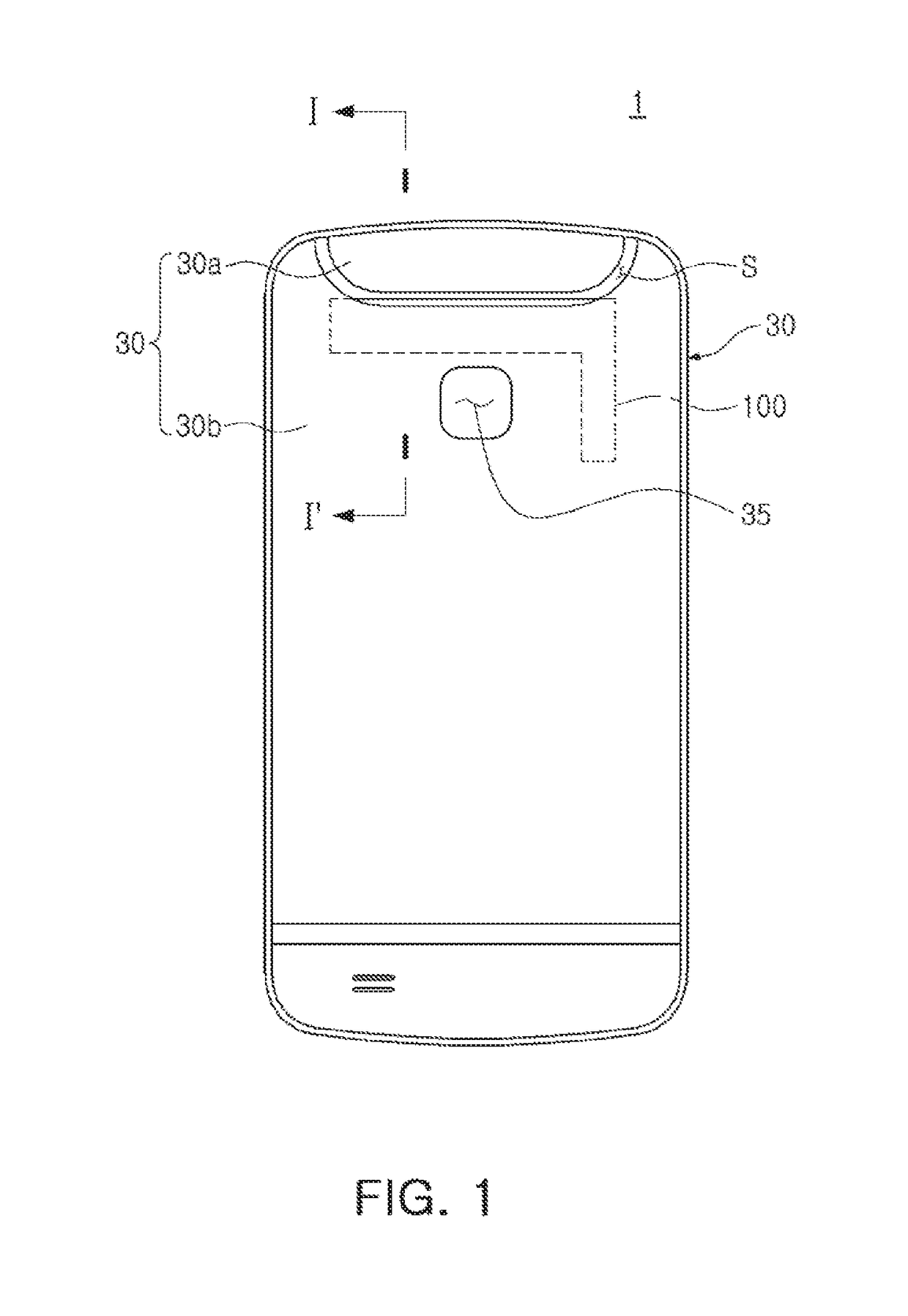

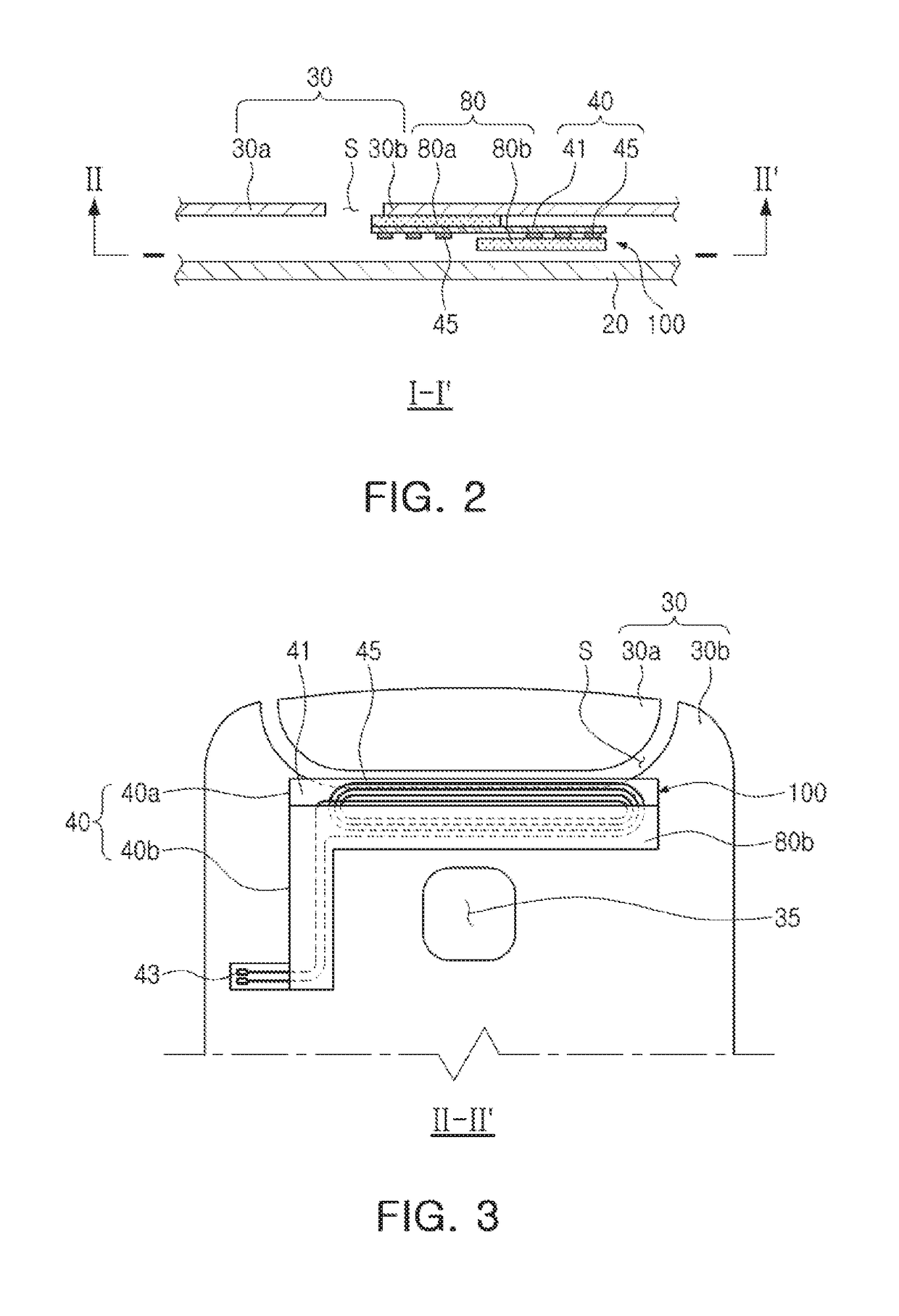

Antenna module and electronic device including the same

ActiveUS20190013568A1Well formedSpace minimizationNear-field transmissionBatteries circuit arrangementsComputer moduleEngineering

Owner:WITS CO LTD

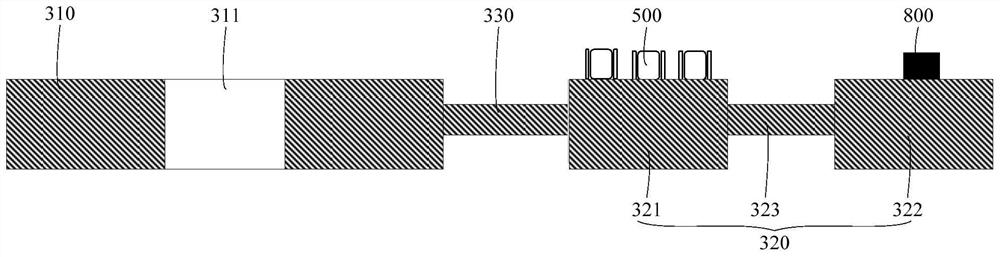

Display assembly and preparation method thereof, display module and electronic equipment

InactiveCN112150970AGood thinnessRealize double-sided display functionStatic indicating devicesSolid-state devicesPhysicsEngineering

The embodiment of the invention relates to a display assembly and a preparation method thereof, a display module and electronic equipment. The display assembly comprises a first light-emitting unit, asecond light emitting unit, and a driving circuit layer which is internally provided with a driving module, wherein the driving module is electrically connected with the first light-emitting unit andthe second light-emitting unit and used for controlling the first light-emitting unit and the second light-emitting unit to emit light; the first light-emitting unit and the second light-emitting unit are respectively arranged on two opposite surfaces of the driving circuit layer. According to the embodiment of the invention, the first light-emitting unit and the second light-emitting unit are respectively arranged on the two opposite surfaces of the driving circuit layer, so that a double-sided display function is realized, and moreover, the first light-emitting unit and the second light-emitting unit are respectively controlled by the same driving circuit layer, so that the display assembly with better lightness and thinness is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

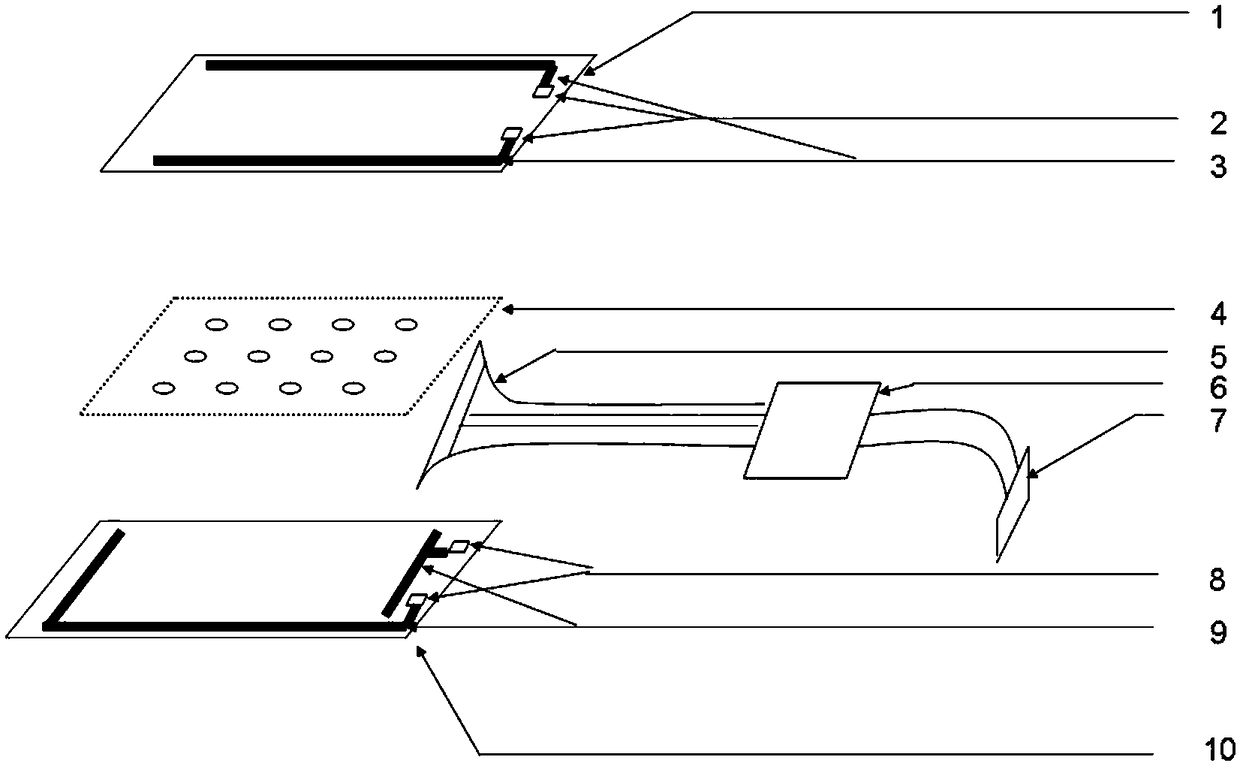

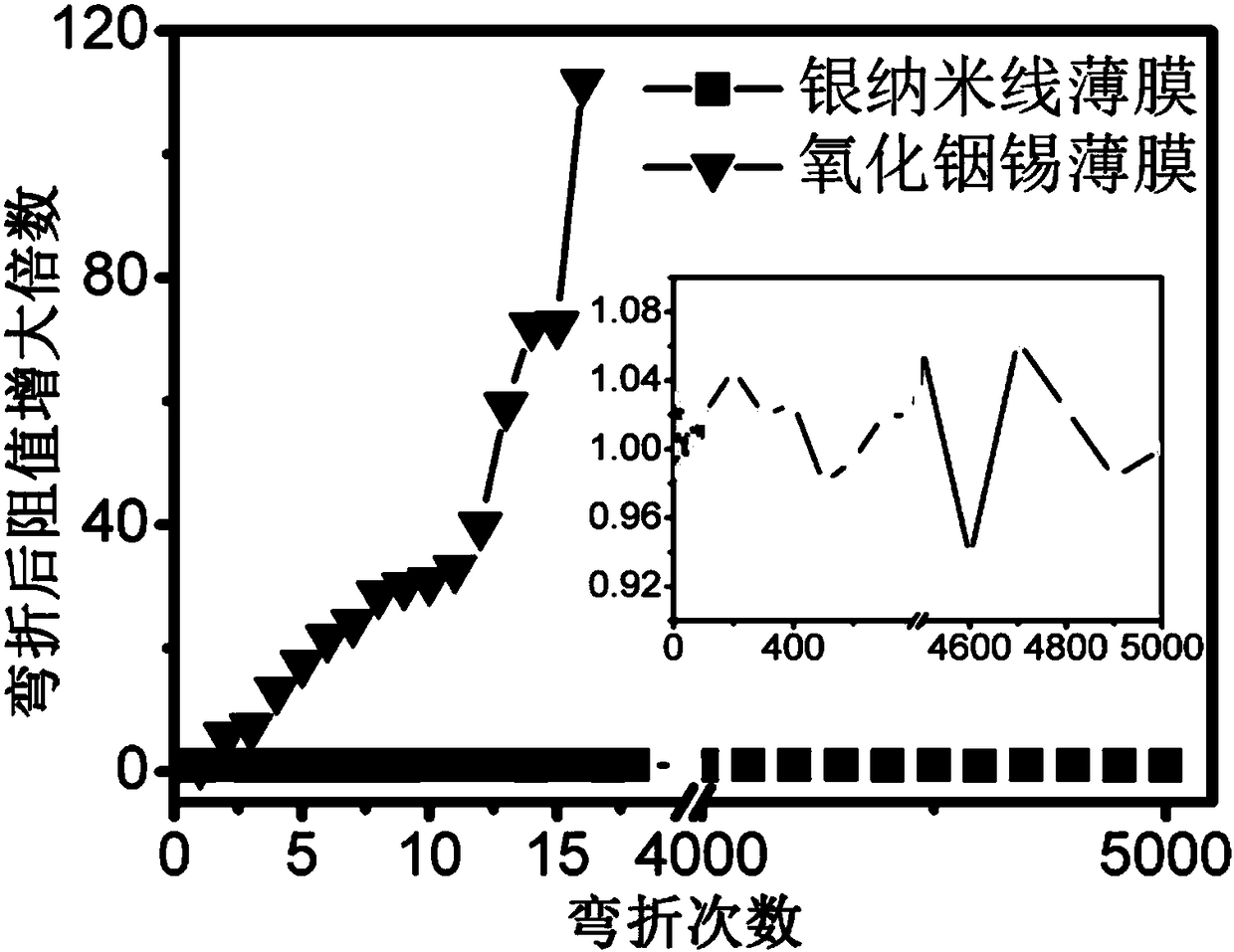

Full flexible transparent touch control system

PendingCN108334243AGood flexibilityStable structureInput/output processes for data processingDot matrixSystems design

The invention discloses a full flexible transparent touch control system which comprises two flexible transparent conducting layers, an insulation isolation dot matrix layer and a periphery conductingelectrode. The flexible transparent conducting layers mainly comprise a transparent conducting film formed by random lap joint of metal nanowires into grids; the insulation isolation dot matrix layeris located between the two flexible transparent conducting layers; an insulation isolation dot matrix is attached to the transparent conducting film of any flexible transparent conducting layer or manufactured on an independent transparent flexible conducting substrate; and two linear electrodes are fabricated on the insulation isolation dot matrix layer substrate and the other transparent conducting film to be connected with peripheral equipment. The hardware system is stable in structure, flexible and variable in configuration and good in flexibility, meets requirements of different performance preferences, and is applicable to touch control instruments in bending and vibration service environments and an intelligent perceptive touch control hardware system design under an instrument movement requirement.

Owner:NANJING SILVERNANO NEW MATERIALS TECH CO LTD

Wiring board, multilayer wiring board, and method for manufacturing the same

InactiveUS20060249833A1Fine surfaceImprove installation densitySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical and Electronics engineering

A method for manufacturing a wiring board comprising an insulating member, comprising: a penetrating hole formation process of forming a penetrating hole in the insulating member; a placement process of inserting a conductive connecting particle into the penetrating hole; a connecting particle pressing process of disposing the conductive layers on both surfaces of the insulating member, pressing the conductive layers toward the connecting particle in the penetrating hole, and deforming the connecting particle in the pressing direction to obtain the connecting member; and a patterning process of patterning the conductive layers, wherein, in the connecting particle pressing process, the pressing is performed such that the cross-sectional area in the direction along the insulating member surface of at least a portion of the connecting member is greater than the contact area of the connecting member with the conductive layers.

Owner:THE FUJIKURA CABLE WORKS LTD

Sandwich structure and integrally formed article using the same, and methods for production thereof

Owner:TORAY IND INC

Wiring board, multilayer wiring board, and method for manufacturing the same

InactiveUS7926175B2Improve compactnessGood thinnessLine/current collector detailsPrinted circuit aspectsElectrical and Electronics engineering

A method for manufacturing a wiring board comprising an insulating member, comprising: a penetrating hole formation process of forming a penetrating hole in the insulating member; a placement process of inserting a conductive connecting particle into the penetrating hole; a connecting particle pressing process of disposing the conductive layers on both surfaces of the insulating member, pressing the conductive layers toward the connecting particle in the penetrating hole, and deforming the connecting particle in the pressing direction to obtain the connecting member; and a patterning process of patterning the conductive layers, wherein, in the connecting particle pressing process, the pressing is performed such that the cross-sectional area in the direction along the insulating member surface of at least a portion of the connecting member is greater than the contact area of the connecting member with the conductive layers.

Owner:FUJIKURA LTD

3D-printing aerogel down fabric and production process thereof

ActiveCN110039847AImprove breathabilityGood thinnessAdditive manufacturing apparatusLayered productsSurface layerEngineering

The invention discloses a 3D-printing aerogel down fabric and a production process thereof. The 3D-printing aerogel down fabric structurally comprises a bottom layer fabric, a binding layer, a wind-proof breathable layer, a columnar aerogel foaming body, an elastic down locking layer, a down layer and a surface layer fabric, wherein the columnar aerogel foaming body comprises an air bag layer, a gel body, an aerogel layer hot melt adhesive and aerogel. Compared with a traditional technology, the 3D-printing aerogel down fabric is additionally provided with the columnar aerogel foaming body, which can successfully fix the aerogel to the fabric, so that a double protection method is adopted to avoid powder dropping in the process of use. In addition, the aerogel enables the whole fabric to have good air permeability and light weight as well as efficient heat preservation effect, the inner waterproofness is realized by virtue of the water-repellent performance of the aerogel, and the comfort is ensured through the all-around elasticity.

Owner:上海泉欣织造新材料股份有限公司

Camera module and electronic equipment

ActiveCN112702498ASave installation spaceReduce volumeTelevision system detailsColor television detailsEngineeringCamera module

The invention discloses a camera module and electronic equipment, and belongs to the technical field of communication equipment, the camera module comprises a lens, an optical filter, a circuit board and a photosensitive chip; the lens and the optical filter are oppositely arranged, the circuit board comprises a first connecting part, a second connecting part and a first flexible bending section, the first connecting part and the second connecting part are connected through the first flexible bending section, and the lens and the first connecting part are located on the two sides of the optical filter respectively. The optical filter is arranged on the surface, deviating from the second connecting part, of the first connecting part, the photosensitive chip is arranged between the first connecting part and the second connecting part, and the photosensitive chip is electrically connected with the circuit board; the first connecting part is provided with a light-transmitting area, the light-transmitting area is arranged opposite to the optical filter, and the photosensitive chip is arranged opposite to the light-transmitting area. According to the scheme, the problem of poor lightness and thinness of the electronic equipment can be solved.

Owner:VIVO MOBILE COMM CO LTD

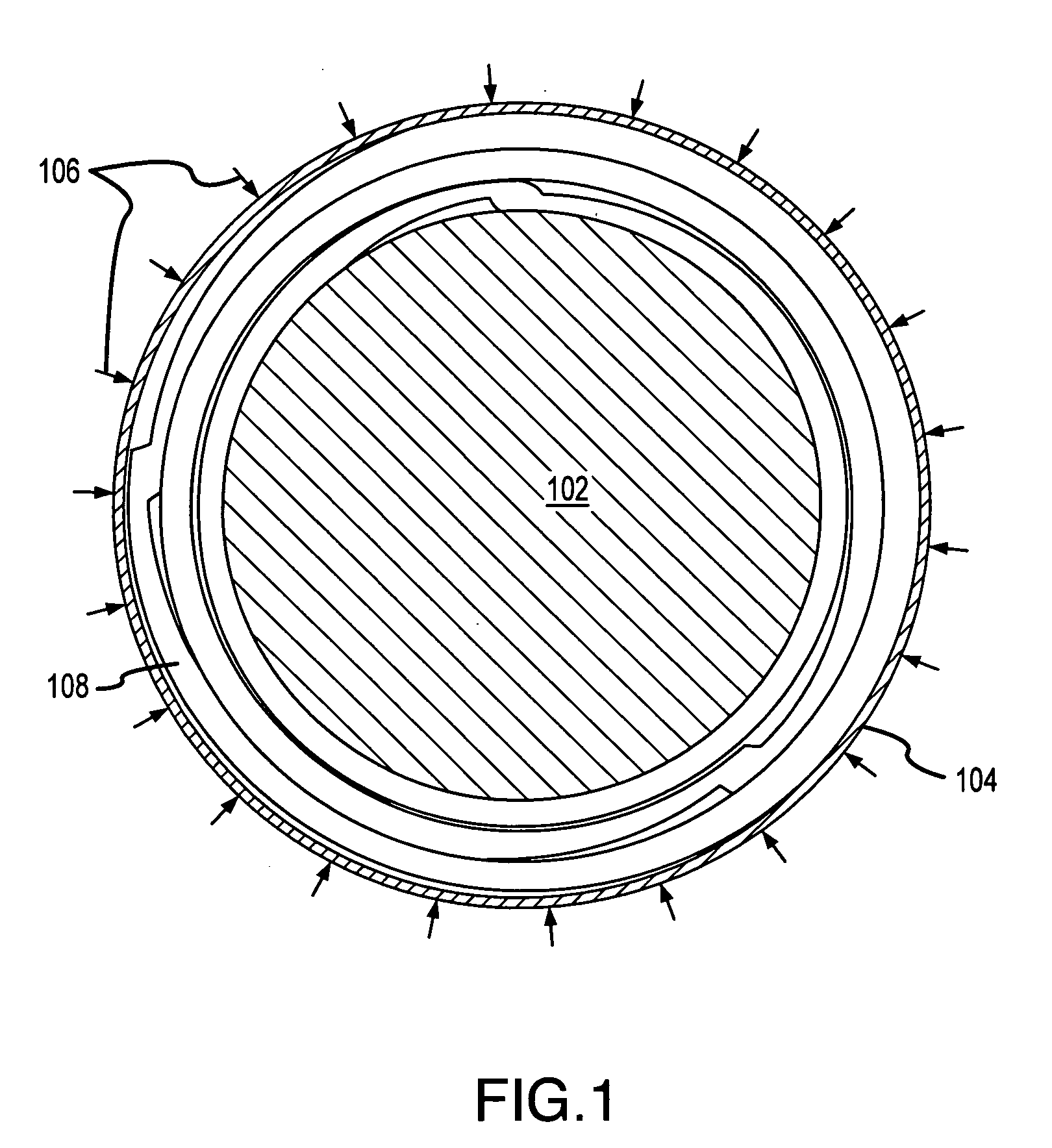

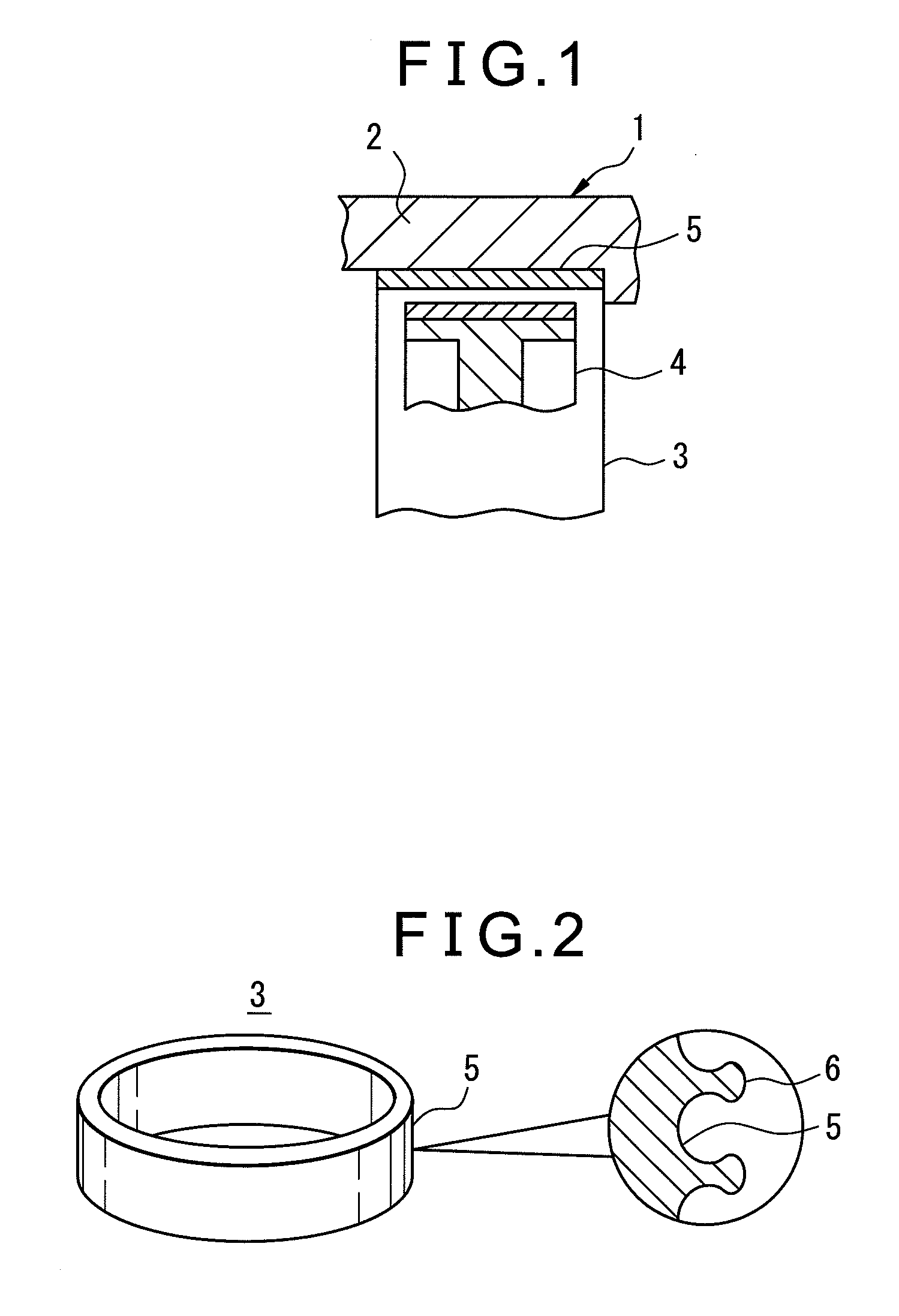

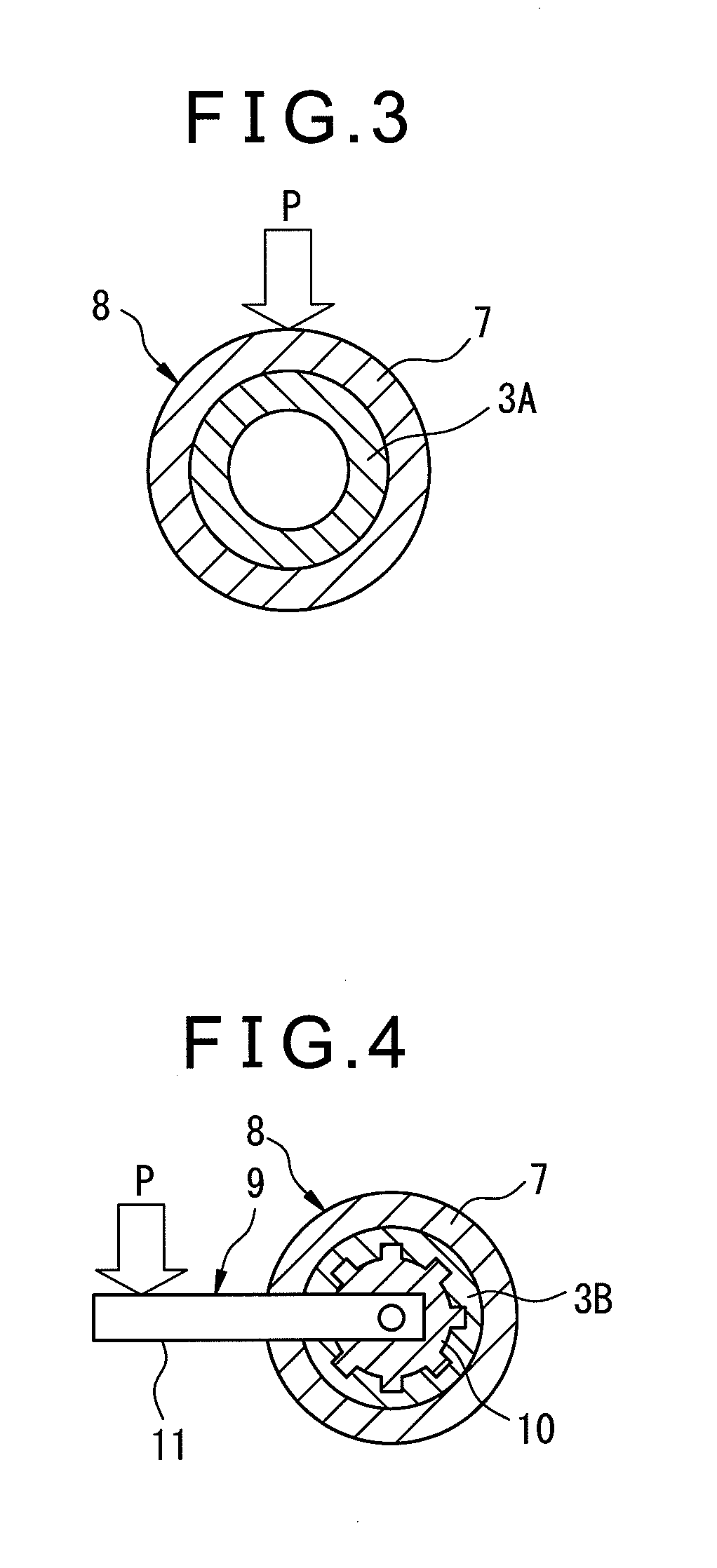

Brake drum

ActiveUS20120228068A1Reduce abnormal noiseImprove joint strengthBraking drumsActuatorsDrum brakeEngineering

A brake drum which can improve the drag strength, strength and rigidity in the diametrical direction, joint strength, and heat radiating ability, that is, a brake drum which is used for a drum brake, wherein the drum has a plurality of the projections at the outer circumferential surface, the plurality of the projections are formed at the outer circumferential surface as a whole when casting a brake drum, and at least part of the projections have thin-waisted shapes. A height of the projections is 0.3 to 5.0 mm, while the number of projections is 5 to 100 / cm2. The brake drum is produced by centrifugal casting.

Owner:TEIKOKU PISTON RING CO LTD +1

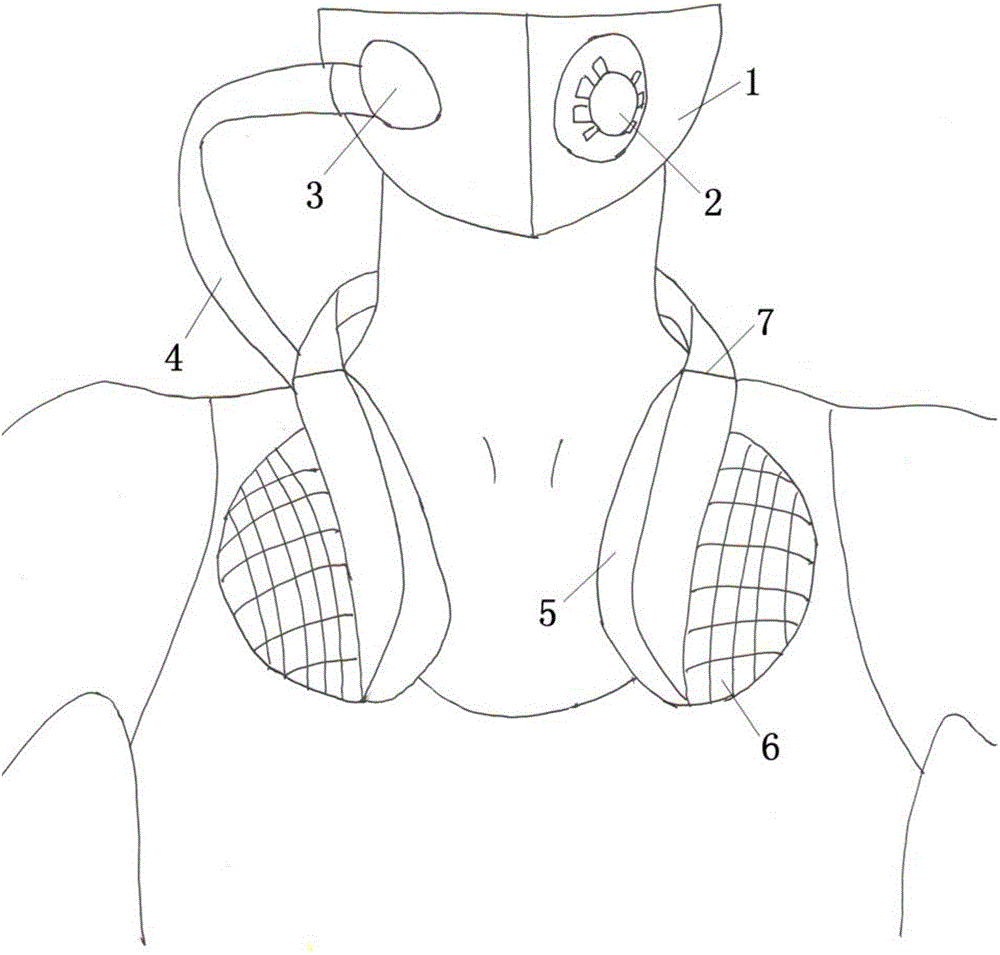

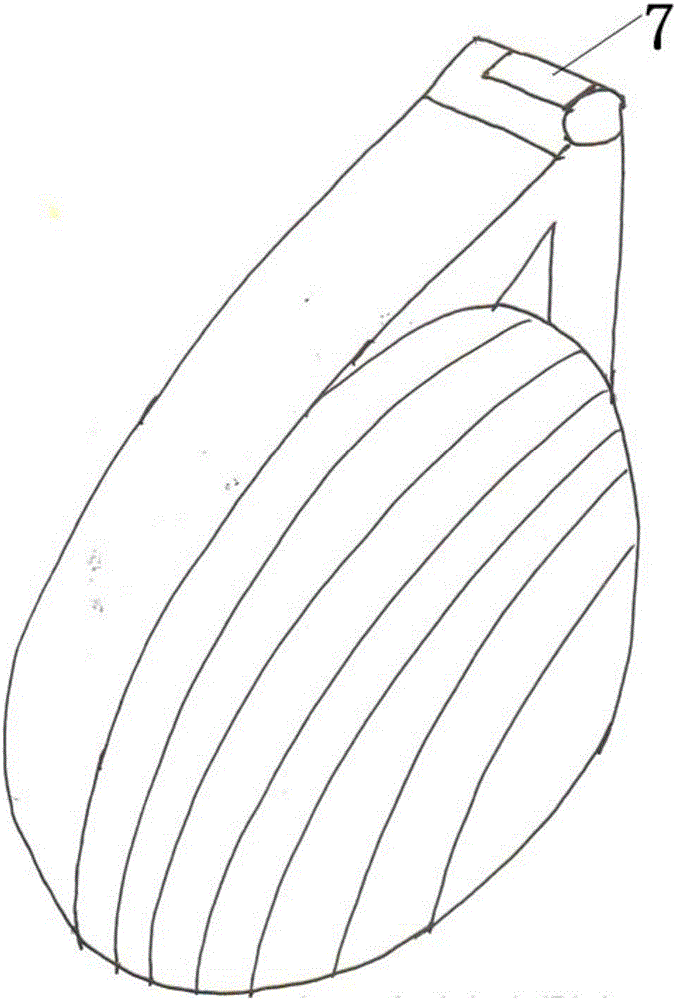

Mask with filtering range broadening function

The invention discloses a mask with a range broadening function. The mask comprises a mask body and a first one-way air valve arranged on the mask body. Ventilation is conducted on the outer side of the mask through the first one-way air valve and is stopped on the inner side. The mask is characterized in that a second one-way air valve is arranged on the mask body, and ventilation is conducted on the inner side of the mask through the second one-way air valve and is stopped on the outer side; one end of an air pipe is connected with the second one-way air valve in a sealed manner, and the other end of the air pipe communicates with a hollow omega-shaped neck sleeve; and a filter is arranged at each of the two ends of the omega-shaped neck sleeve. According to the mask, the filters are externally arranged and communicated through the air pipe, and the size limit disadvantage is well solved; and furthermore, the two one-way air valves independent of each other are arranged on the mask, the good light and thin performance is kept for the mask body, the filters can be carried more conveniently due to the design of the neck sleeve, and the mask is especially suitable for the outdoor work.

Owner:DALIAN UNIV OF TECH

Light, thin and soft formal dress fabric

InactiveCN107183813AGood thinnessSoft touchProtective garmentSpecial outerwear garmentsPolyamide fibersSilk fiber

The invention discloses a frivolous and soft dress fabric, which comprises: wool fabric fiber, plush fiber, barbeque fiber, corn fiber, silk fiber, linen, polyamide fiber, peanut fiber and polypropylene fiber, wherein the light and thin The weight fraction of each component in the soft dress fabric: 1-7 parts of wool fabric fiber, 3-6 parts of plush fiber, 5-9 parts of voile yarn fiber, 2-4 parts of corn fiber, 3-5 parts of real silk fiber, flax 4‑6 parts, polyamide fiber 5‑7 parts, peanut fiber 5‑8 parts and polypropylene fiber 6‑8 parts. Through the above method, the thin and soft dress fabric provided by the present invention has good light and thin characteristics and soft touch, which can meet people's needs.

Owner:苏州凤霓绣叶文化艺术有限公司

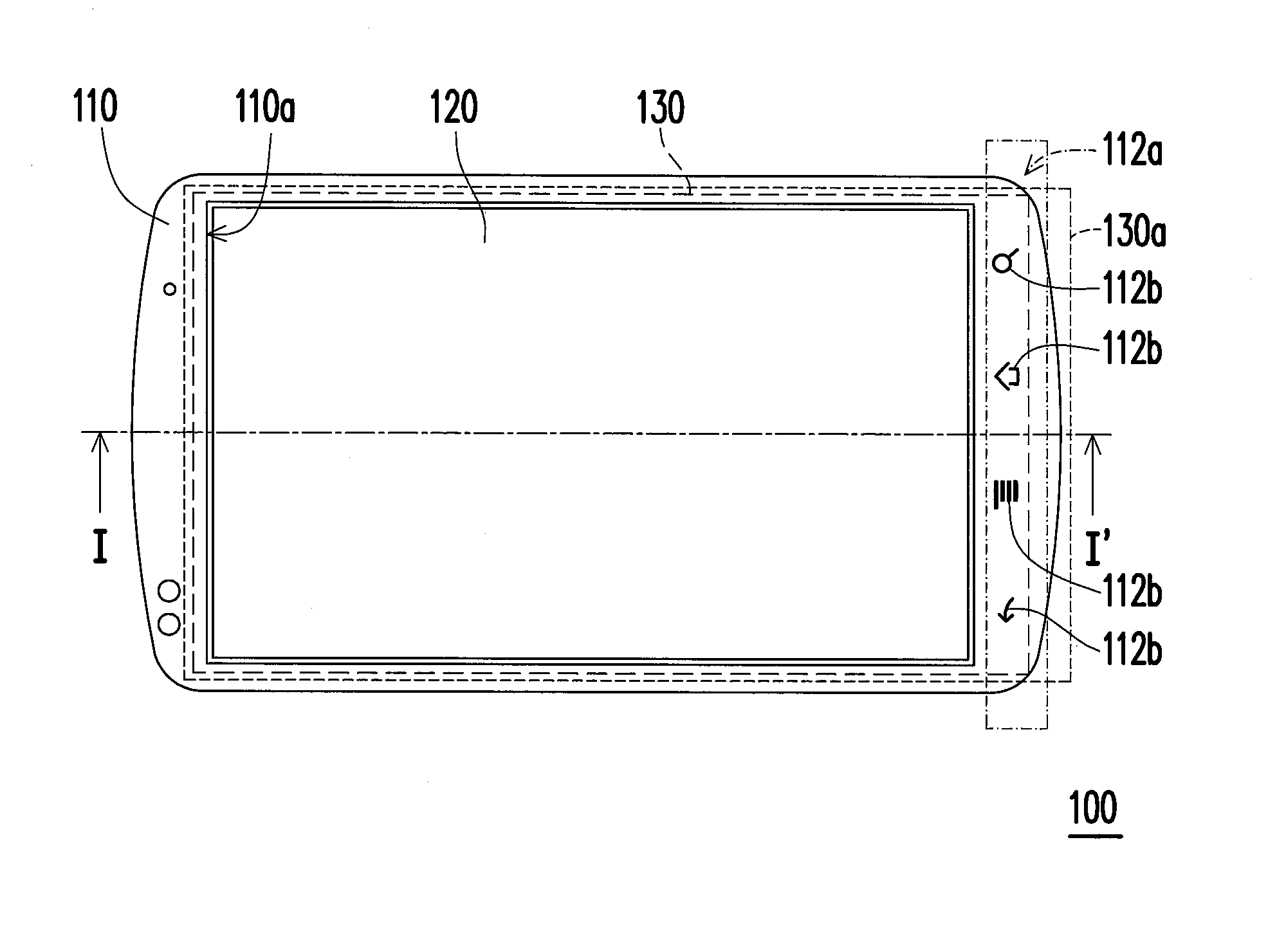

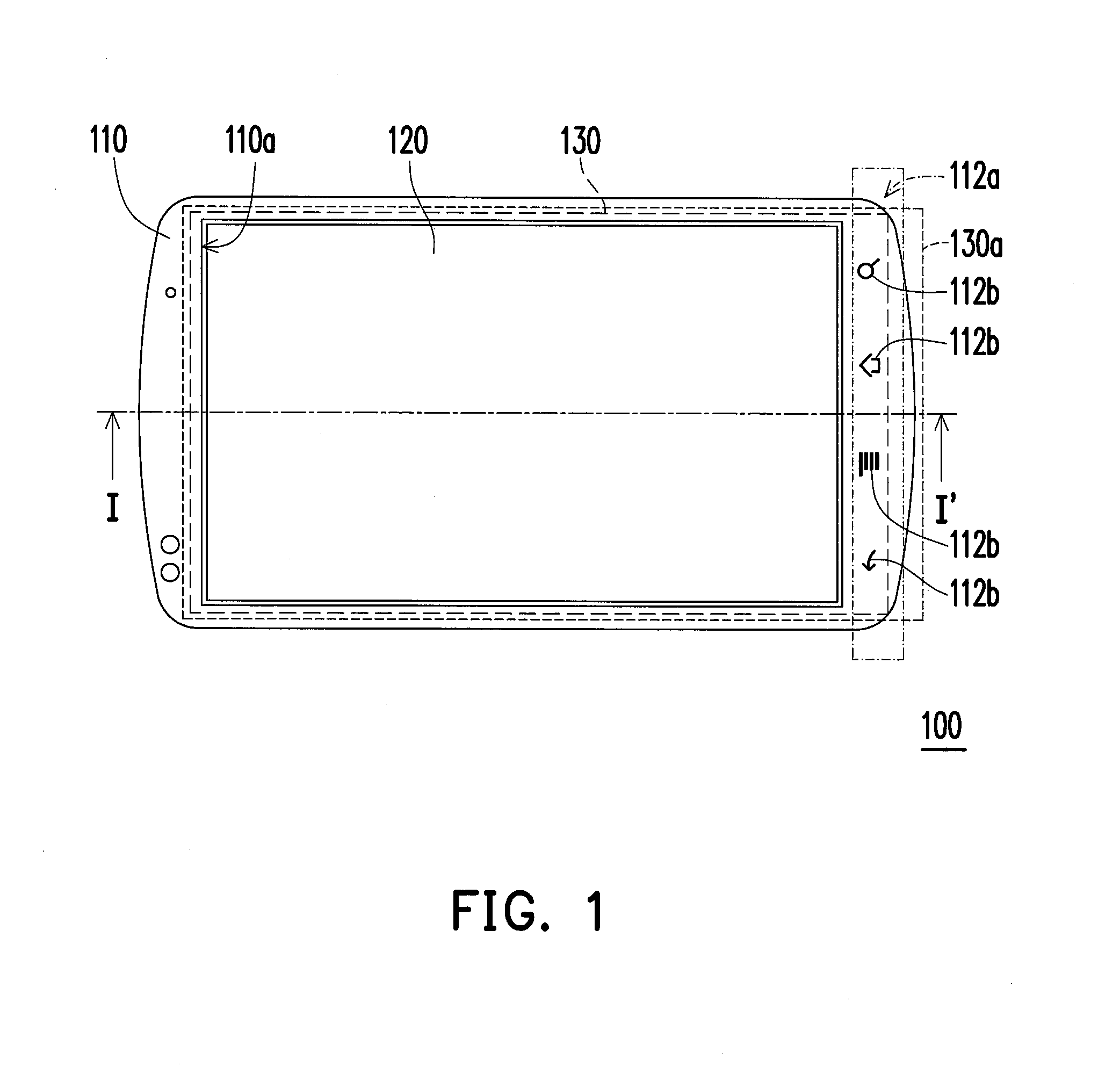

Handheld electronic device

InactiveUS20130141341A1Lighter componentReduce the amount of lightDigital data processing detailsPlanar/plate-like light guidesEngineeringLight source

A handheld electronic device including a housing, a display panel and a backlight module is provided. The housing has a display opening and a transparent region located outside of the display opening. The display panel is disposed in the display opening. The backlight module is disposed in the housing. The backlight module has a light emitting region which is located under the display panel, adapted to provide a plane light source to the display panel. The light emitting region further extends to outside of the display panel so that a part of the plane light source is sent out the housing through the transparent region.

Owner:HTC CORP

Insulation cotton containing aerogel and production process thereof

InactiveCN110696453AGood air permeabilityGood thinnessSynthetic resin layered productsCellulosic plastic layered productsPolyesterPolymer chemistry

The invention discloses insulation cotton containing aerogel and a production process thereof. The insulation cotton comprises a bottom polyester cotton layer, a TPU film layer, a material layer and asurface polyester cotton layer, wherein the material layer is wrapped in the TPU film layer, and the TPU film layer is arranged between the bottom polyester cotton layer and the surface polyester cotton layer, wherein the material layer comprises a polyester cotton layer and 1-20% of the aerogel, and the polyester cotton layer comprises 0-60% of down feather, 20-99% of polyester and 0-60% of cuprammonium silk fibers. Compared with the traditional technology, the process successfully adds the aerogel to a fabric material safely, overcomes the problems of difficult processing, volatilization and high danger of the aerogel, and enables clothes to have good air permeability, lightness and thinness and simultaneously have high-efficiency heat preservation effect, inner layer waterproofness canbe realized due to water repellency, and simultaneously the insulation cotton has four-sided elasticity to ensure comfort.

Owner:上海泉欣织造新材料股份有限公司

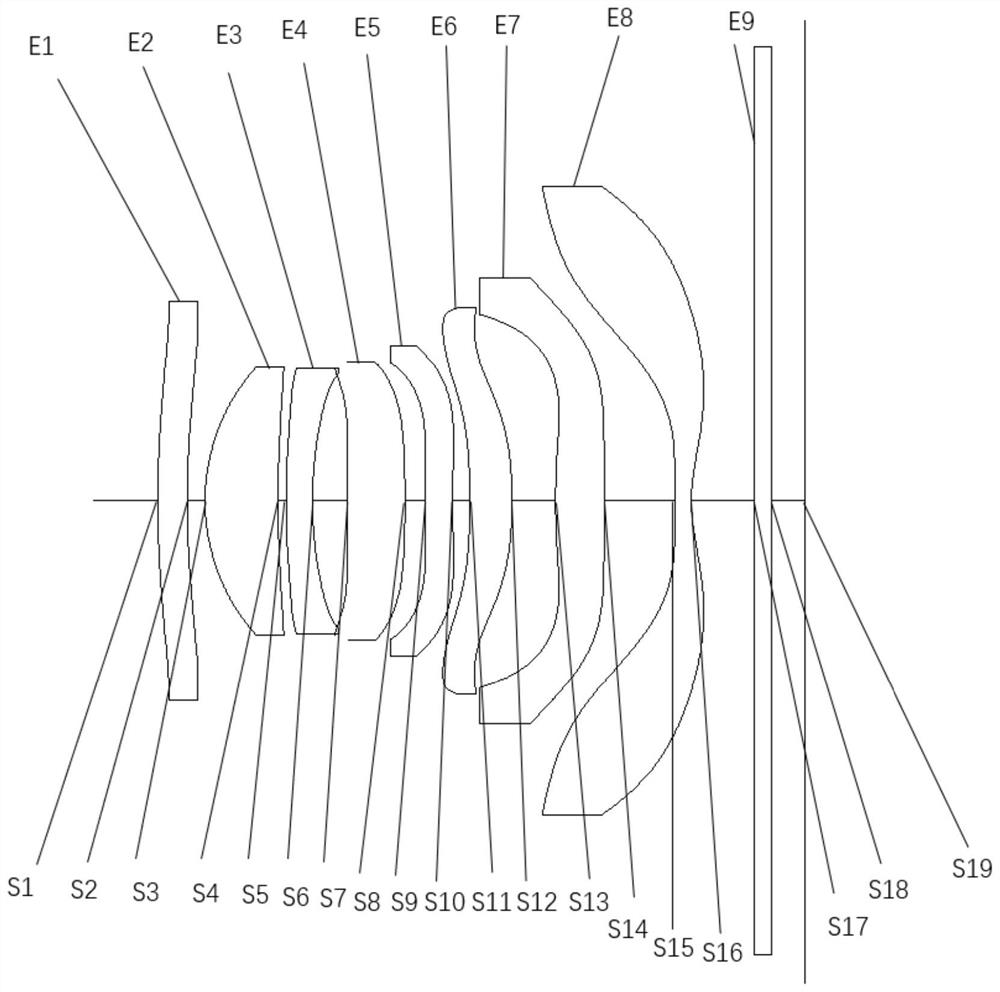

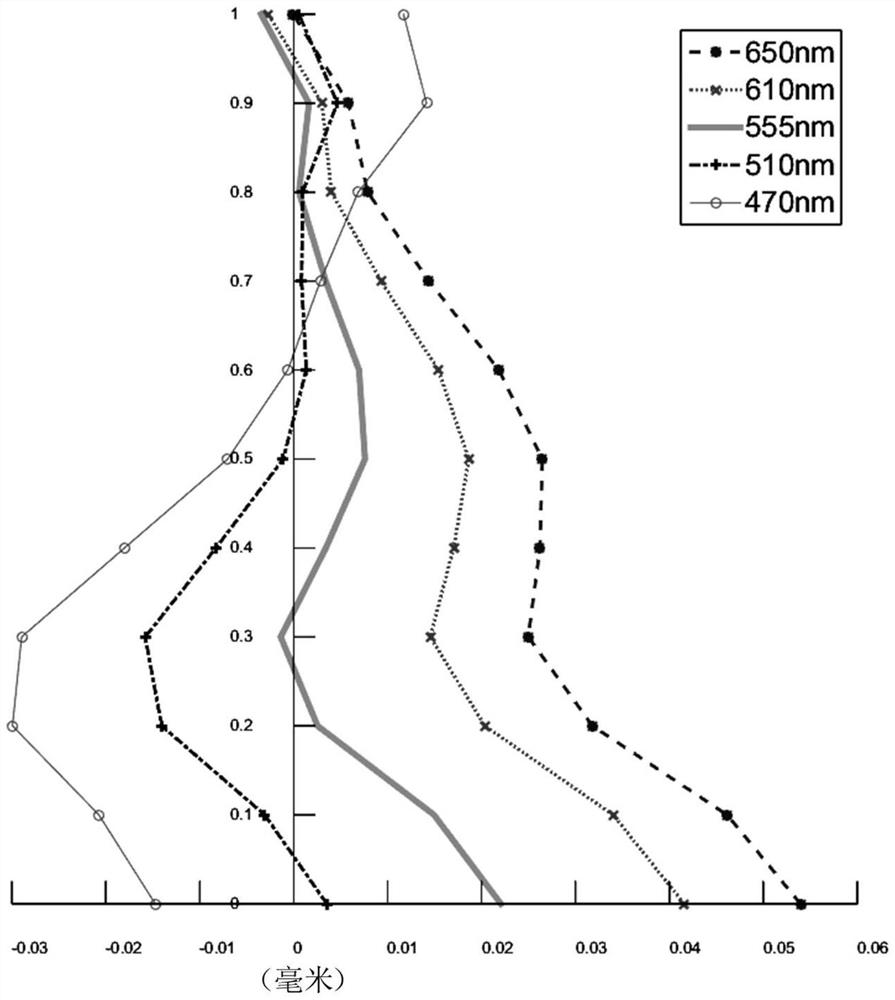

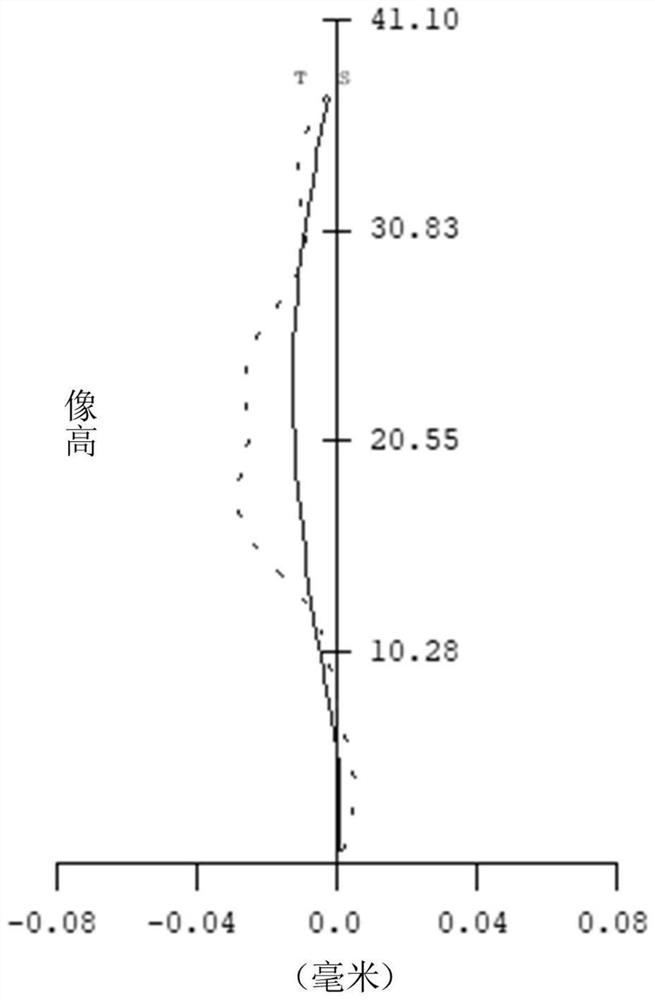

Optical imaging lens and electronic equipment

InactiveCN112305837AThin and lightweightWith super wide angleMountingsCamera body detailsOphthalmologyOptical axis

The invention discloses an optical imaging lens and electronic equipment, and belongs to the technical field of optical imaging. The optical imaging lens comprises a shell, a first lens, a lens groupand a photosensitive element. The shell is provided with a light transmitting hole and an inner cavity, the light transmitting hole is connected with the inner cavity, the first lens is arranged in the light transmitting hole, and the lens group and the photosensitive element are arranged in the inner cavity; and the lens group is located between the first lens and the photosensitive element, andambient light can sequentially pass through the first lens and the lens group to be projected to the photosensitive element. The lens group comprises at least two lenses which are sequentially arranged on the optical axis of the optical imaging lens, and the optical imaging lens further comprises a driving mechanism which is in driving connection with at least parts of the lenses of the lens groupand drives the lenses to move on the optical axis relative to the photosensitive element. According to the scheme, the problem that an existing optical imaging lens cannot give consideration to shooting quality and structure lightness and thinness is solved.

Owner:VIVO MOBILE COMM CO LTD

Preparation method of capacitive touch screen

ActiveCN103309538BReduce thicknessThin and lightInput/output processes for data processingPolyethylene terephthalateIndium tin oxide

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

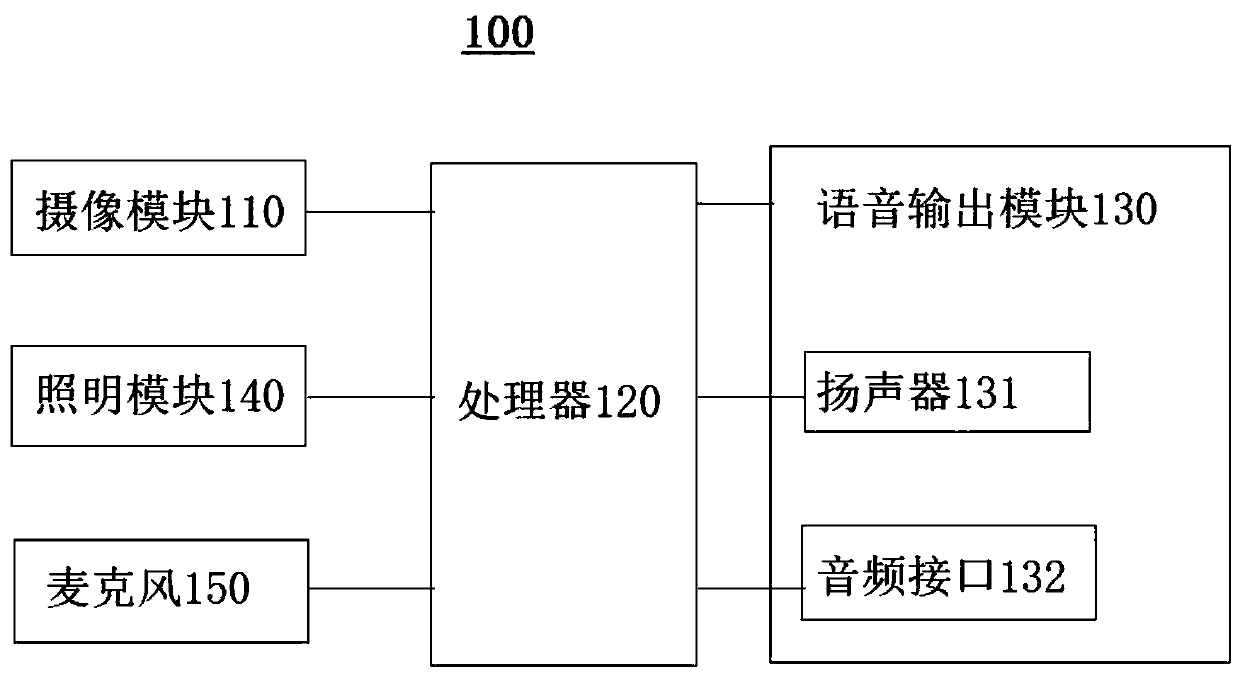

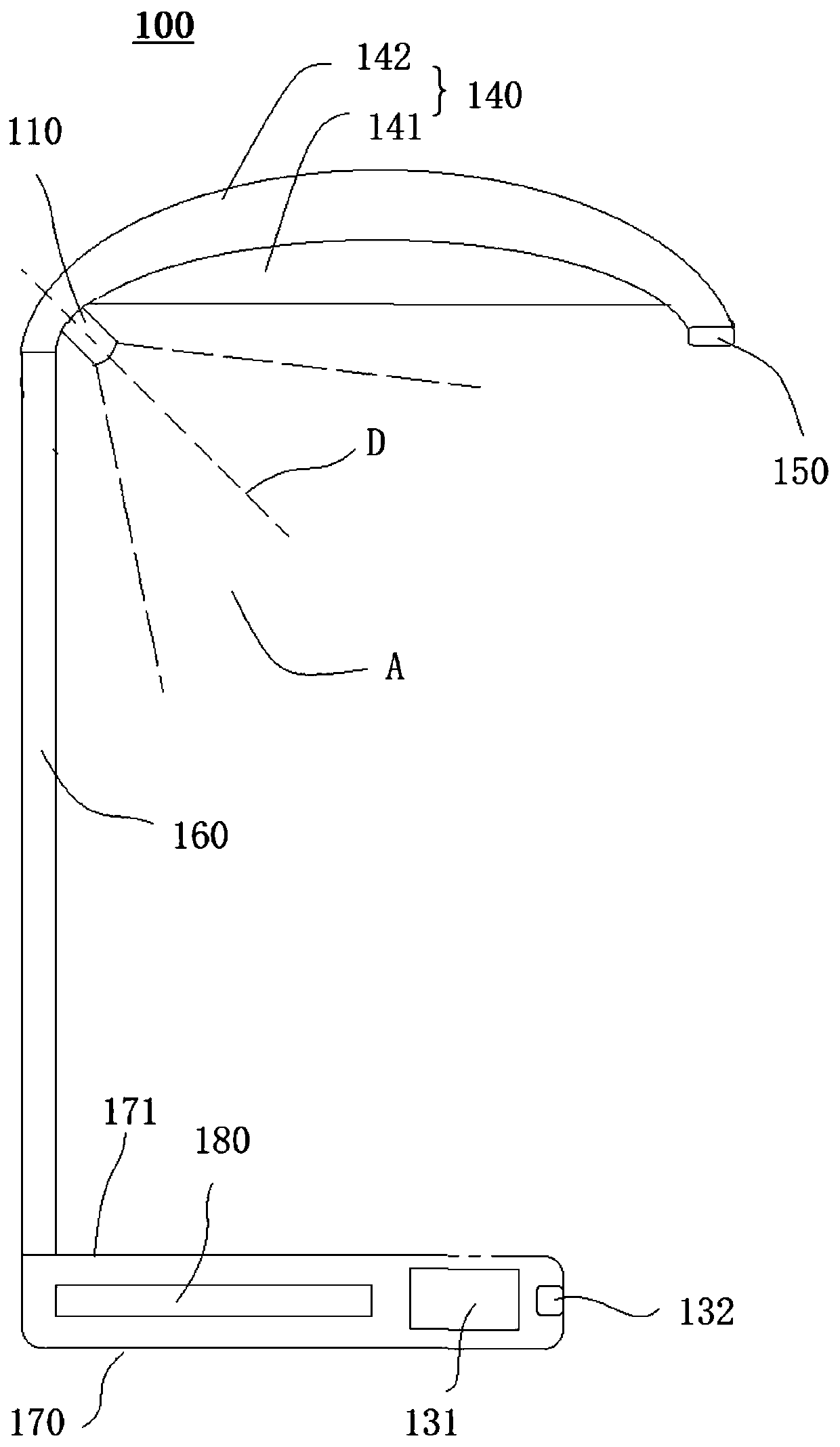

Intelligent auxiliary learning device

PendingCN111405135AReduce radiationStrong learning supportElectrical appliancesPictoral communicationMachine learningEngineering

The invention provides an intelligent auxiliary learning device. The intelligent auxiliary learning device comprises a camera module, a processor and an audio output module. The camera module is usedfor tracking the action of a hand or a reading auxiliary device when a user reads a text and transmitting a video image to the processor; the processor is used for analyzing the video image, when theaction of the hand or the reading auxiliary device during reading of the user conforms to a preset action, the processor acquires a part of text image pointed by the action of the hand or the readingauxiliary device, performs translation, analysis and / or network entry search on the part of text image to acquire an analysis result, and outputs the analysis result through the audio output module.

Owner:SHENZHEN AUSDOM CLOUD TECH CO LTD

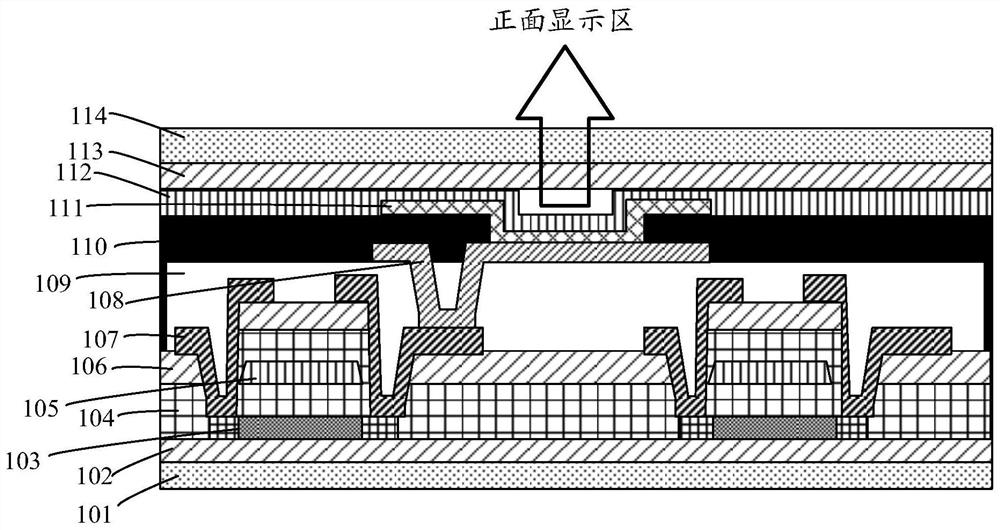

Electronic equipment and manufacturing method of double-sided display screen

PendingCN112687724AGood thinnessSimple structureSolid-state devicesSemiconductor devicesControl systemMaterials science

The embodiment of the invention provides electronic equipment and a manufacturing method thereof. The electronic equipment at least comprises a display screen control system and a double-sided display screen; the double-sided display screen comprises a first substrate, a first display unit and a second display unit arranged on the first substrate, and a second substrate covering the first display unit and the second display unit; the first display unit at least comprises a first anode, a first cathode and a first light-emitting layer, and light emitted by the first light-emitting layer is emitted from the second substrate; the second display unit at least comprises a second anode, a second cathode and a second light-emitting layer, and light emitted by the second light-emitting layer is emitted from the first substrate; and the second anode and the first cathode are formed by the same process.

Owner:LENOVO (BEIJING) CO LTD

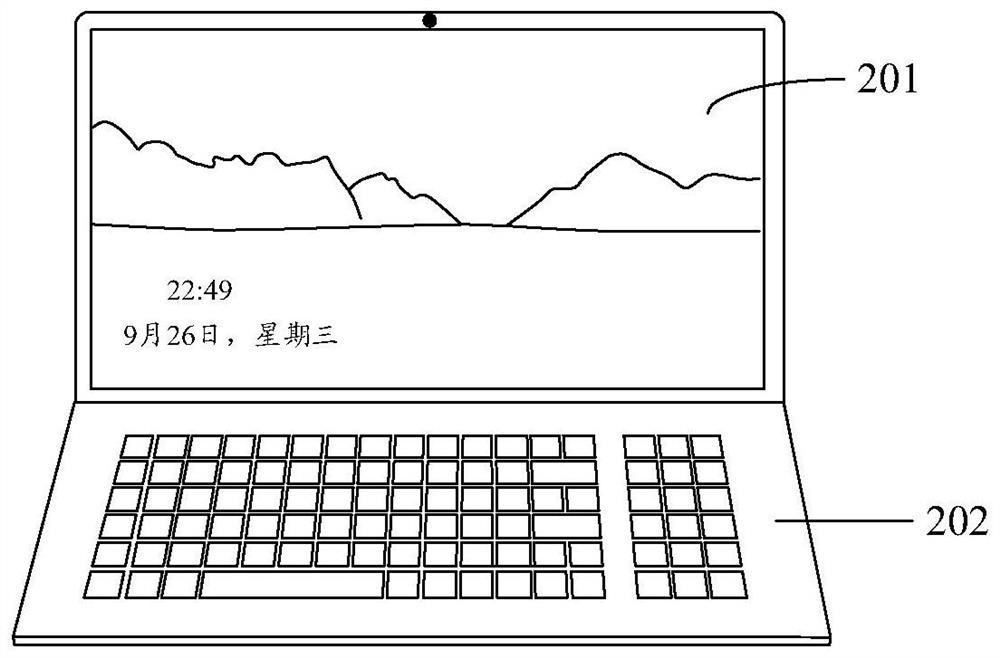

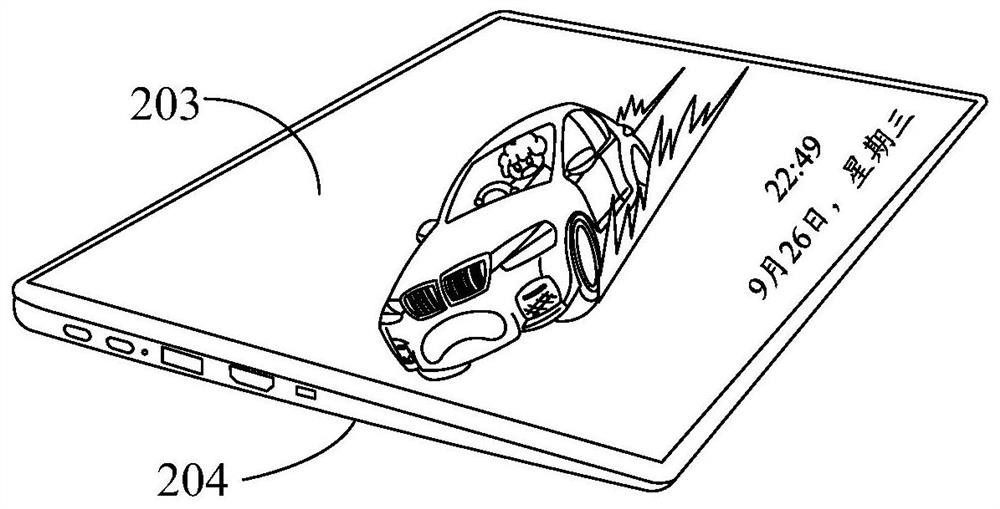

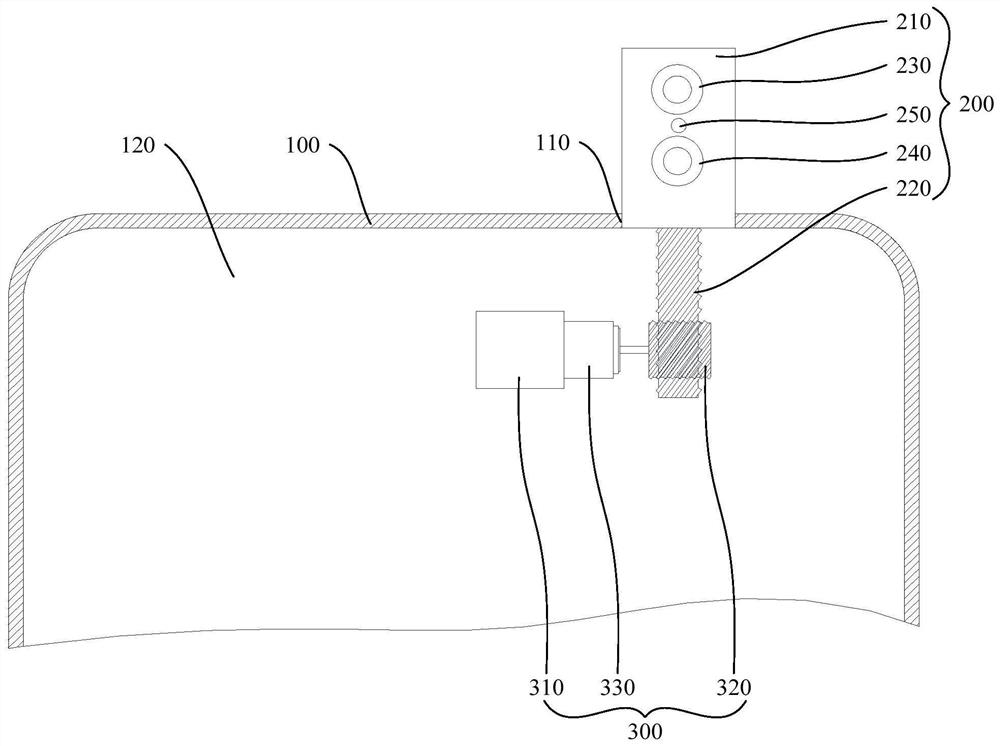

Terminal Equipment

ActiveCN109803074BReduce thicknessGood thinnessTelevision system detailsColor television detailsTerminal equipmentEngineering

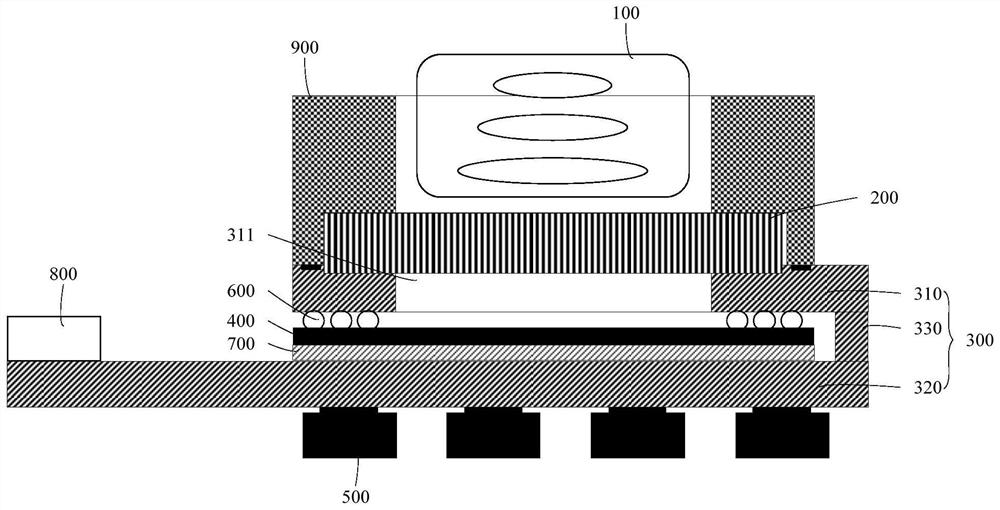

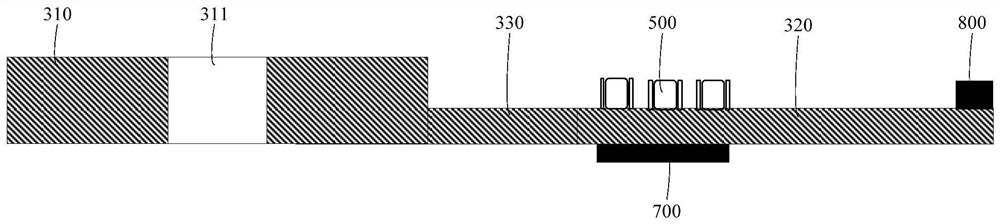

The invention discloses a terminal device, which comprises a casing (100) provided with a perforation (110), a camera assembly (200) movably arranged in the casing (100), and a driving mechanism arranged in the casing (100) (300), the camera assembly (200) enters and exits the housing (100) through the perforation (110), the drive mechanism (300) is connected to the camera assembly (200) in transmission, and the drive mechanism (300) applies rotational drive to the camera assembly (200) Under the action of the rotational driving force, the camera head assembly (200) rotates relative to the housing (100) with the central axis through the hole (110) as the rotation axis. The camera assembly can be rotated so as to face the front, the back or other positions of the terminal device according to the needs of the user. It can be seen that the terminal device can realize front-facing shooting and rear-facing shooting at the same time through the one camera component, and there is no need to set up a front-facing camera and a rear-facing camera separately, so that the thickness of the terminal device is reduced and its thinness is improved.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

Mask structure of LCD display screen and manufacturing process thereof

The invention relates to the field of LED display screens. The invention relates to a mask structure, in particular to an LCD display screen mask structure and a manufacturing process thereof. An outer shell of the LED display screen comprises a pressing plate and a mask. The mask is attached to the upper plane of the pressing plate, a plurality of light transmitting holes are formed in the pressing plate, a plurality of light scattering holes are formed in the mask, the light scattering holes and the light transmitting holes are located on the same axis, and the surface treatment process comprises the following steps that S1, the pressing plate and the mask are subjected to pressing treatment in a precision stamping mode; S2, epoxy resin is filled; and S3, the mask is subjected to pressing treatment in a vacuum closed environment. According to the invention, through multi-line refraction of light, the light is uniformly mixed, and the emitted light has few mixed colors, so that the black and white contrast of the display screen is improved, and the brightness of the light is more uniform.

Owner:HEFEI PRECISE DISPLAY CO LTD

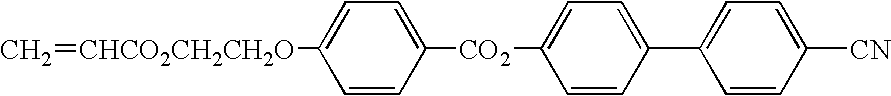

Wide viewing angle polarizer and liquid-crystal display device

InactiveUSRE41679E1Improve viewing angleReduce thicknessPolarising elementsNon-linear opticsPolarizerWavelength range

A wide viewing angle polarizer having: a polarizing film; and a phase retarder adhesively laminated on at least one surface of the polarizing film through an adhesive layer, the phase retarder being made of a composite phase retarder constituted by a laminate in which a retardation layer B of a cholesteric liquid crystal-oriented solidified layer in a selective reflection wavelength range of not larger than 350 nm is supported by a retardation layer A of a thermoplastic resin exhibiting positive birefringence, the composite phase retarder being formed so that the laminate has Re of not smaller than 10 nm and Rth−Re of not smaller than 50 nm when Re and Rth are defined as Re=(nx−ny)X d and Rth=(nx−nz)X d respectively in which nx and ny are in-plane main refractive indices, nz is a thicknesswise refractive index, and d is a layer thickness. A liquid-crystal display device having: a liquid-crystal cell; and a wide viewing angle polarizer defined above and disposed on at least one surface of the liquid-crystal cell.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com